24

December

2014

HYDROCARBON

ENGINEERING

example. The firm is able to provide this transportation based on

a network of carriers that specialise in these kinds of unusual

requirements.

A typical overseas spent catalyst shipment, perhaps from an

oil refinery in Abu Dhabi or a petrochem refinery in Brazil would

work something like this: First, the catalyst owner advises SILC

on the pending shipment of spent precious metal bearing

catalysts. SILC’s people discuss the shipment with an

international freight forwarder which contacts a local freight

forwarder in the exporting country to help facilitate

transportation arrangements and, in some cases, assist the

customer with documentation requirements or other requests.

This process is usually done quickly; it is

also done simultaneously when there are

split shipments of spent catalysts that are

scheduled for recovery and refining in

two different Sabin processing facilities.

Obviously, time is of the essence with

regard to faster settlements for the

customer so as to eliminate or minimise

the need for purchasing or leasing

replacement precious metals for a new

catalyst campaign. SILC processes

shipments simultaneously in order to

speed up the process.

Prior to the introduction of SILC’s

SA-BINs, there were occasional issues

concerning how a customer might load

and safely store large volumes of spent

catalysts prior to shipment to a Sabin

recovery and refining processing facility.

Depending upon circumstances, spent

catalysts were stored in drums or other

types of shipping containers. SA-BINs are

significantly easier and faster to load

than standard storage shipping drums. A

SA-BIN will typically contain

approximately 3000 lbs of material; this

is approximately eight to 10 times more

material than a single 55 gal. drum. They

are also more durable than ‘supersacks’,

which might tear or tip over during

loading and/or shipping. Also, from a

cost perspective, SA-BINs offer

significant savings versus supersacks or

drums since they are supplied at no

charge by the company.

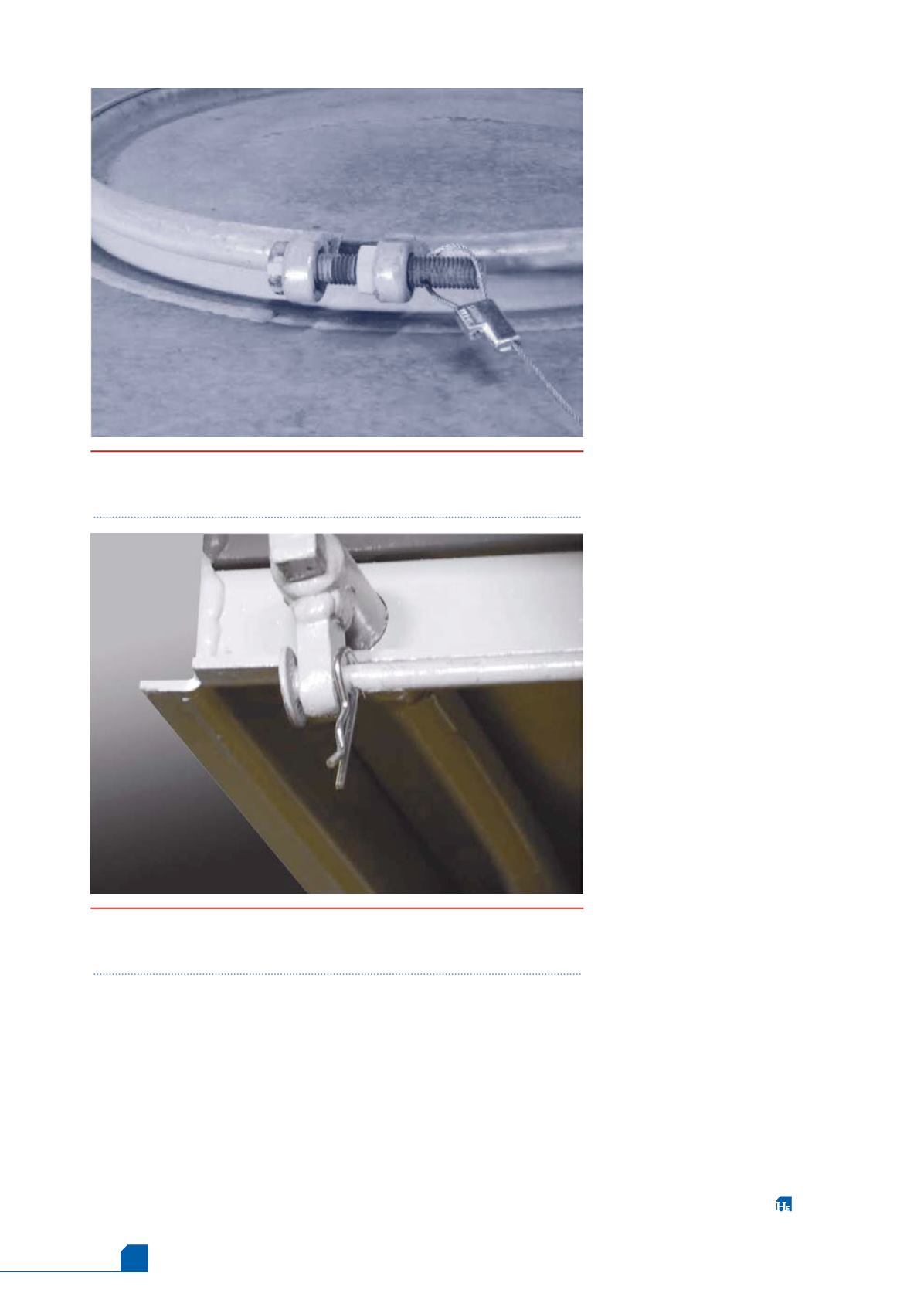

SA-BINs are filled from the top after

a catalyst campaign, and they are

emptied from the bottom at the Sabin

Metal refinery. To assure maximum

storage and shipping security, their tops

are sealed with a locking ring surrounding

the lid and top opening. A tamper

evident cable seal closure secures the lid

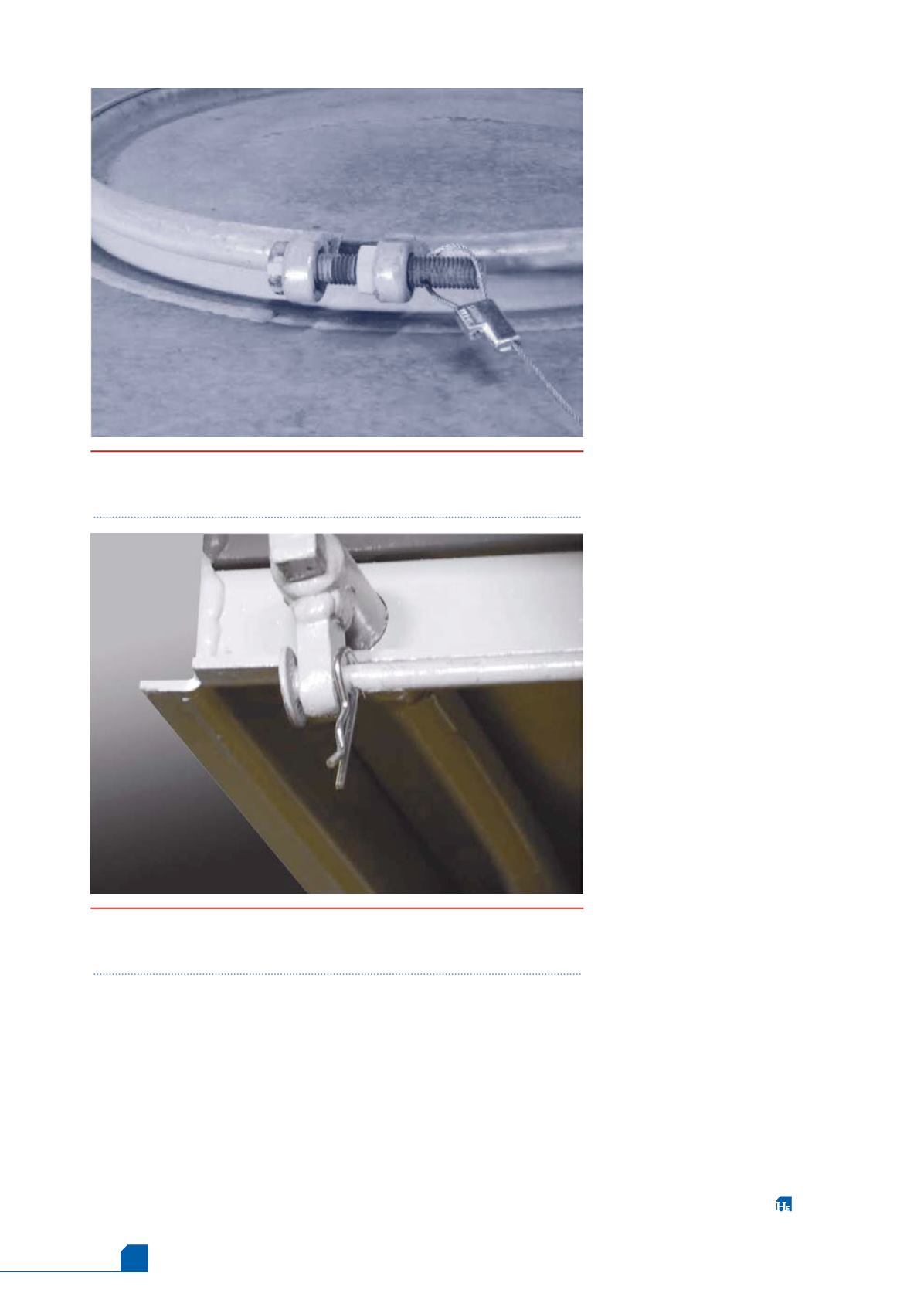

in place (Figure 3). The bottoms of the

SA-BINs also incorporate a locking

mechanism with dual camshafts which

hold the slide gate closed. Once closed,

the camshafts are locked (Figure 4)

virtually eliminating all possibility of material leaking out during

handling or transport.

Conclusion

Keep in mind that in addition to shipping and handling issues,

there are many other criteria to be aware of when working with

a precious metals refiner. Among them are turnaround time,

recovery/refining procedures such as sampling and assaying, and

compliance with appropriate environmental regulations. These

are considered the most critical issues to evaluate, since any

relationship with a precious metals refiner essentially

constitutes a ‘partnership’, for better or for worse.

Figure 3.

To further assure security of spent precious metal bearing

catalysts, SA-BIN's are sealed at their tops with a locking ring (with

tamper evident cable) surrounding the lid and top opening.

Figure 4.

A locking mechanism with dual camshafts on each SA-BIN

virtually eliminates the possibility of materials leaking during

handling or transport.