orientierte Polymere’ Mh. Chem. 1964, 95, pp. 1225 - 1227.

7. THORET BAUCHET, J.-P., ALCURI, G., ‘Process to monitor unwanted

formation of polymer having internal strain by acoustic emission analysis’

US 2010/0162816 A1.

8. BREITENBACH, J. W., AXMANN, H. ‘Popcorn Polymers’, Polymerization

Kinetics and Technology; American Chemical Society: Washington, DC,

1973. pp. 110 - 124.

9. MILLER, G. H., LEUNG, H. ‘Polyisoprene Popcorn’ J. Macromol. Sci.-Chem.

A, 1970, 4 (8) pp. 1705-1717. MILLER, G.H., PERIZZOLO, A.F., J. Polymer

Sci., 18, 411, 1955.

10. MILLER, G. H., PERIZZOLO, A. F., ‘Styrene Popcorn Polymer’ J. Polymer

Sci., 1955, 18, pp 411-416.

11. MILLER, G.H. , ALUMBAUGH, R.L., BROTHERTON, R.J., ‘Butadiene

Popcorn Polymer’, J. Polym. Sci., 1952, 9, (5) pp. 453 - 462.

12. KORF, S.J., SEIFERT, S.S., The identification of butadiene popcorn polymer,

AIChE 92B. Prepared for presentation at 2013 Spring National Meeting,

San Antonio, Texas, April 30, 2013.

13. MILLER, G. H. ‘Oxidation of butadiene popcorn polymer’ J. Polym. Sci.,

(1953), 11: pp. 269 – 276.

Notes

14. The survey is described as non-exhaustive because the incident review

was limited to cases available within the Nalco Champion database,

which includes treated and untreated units.

15. SPPT method

Styrene should be inhibitor free. Remove inhibitor (TBC) by mixing 540 gram

styrene with 100 g of Selexsorb CD. Store solution for one day.

Reference: styrene polymerisation. Fill two PE vials with 15 gram of styrene

and cap under nitrogen (preferably in a glove box).

Reference: styrene polymerisation with lab popcorn. Add 0.5 gram of reference

popcorn in each vial. Add 15 g of styrene under nitrogen. Cap under nitrogen

in a glove box.

Sample: styrene polymerisation with plant sample. Add 0.5 grams of sample in

a vial. Add 15 gram of styrene under nitrogen, cap and store in a glove box.

Heat vials in an oven at 60 °C.

Styrene polymerisation is slow at this temperature, and takes a few days.

Styrene polymerisation will become viscous and finally a transparent

glassy polymer will result after a week. The styrene polymerisation with

reference popcorn will be faster. Due to the popcorn the polymerisation is not

homogeneous. The viscosity of the bulk styrene is increasing much faster when

popcorn is present.

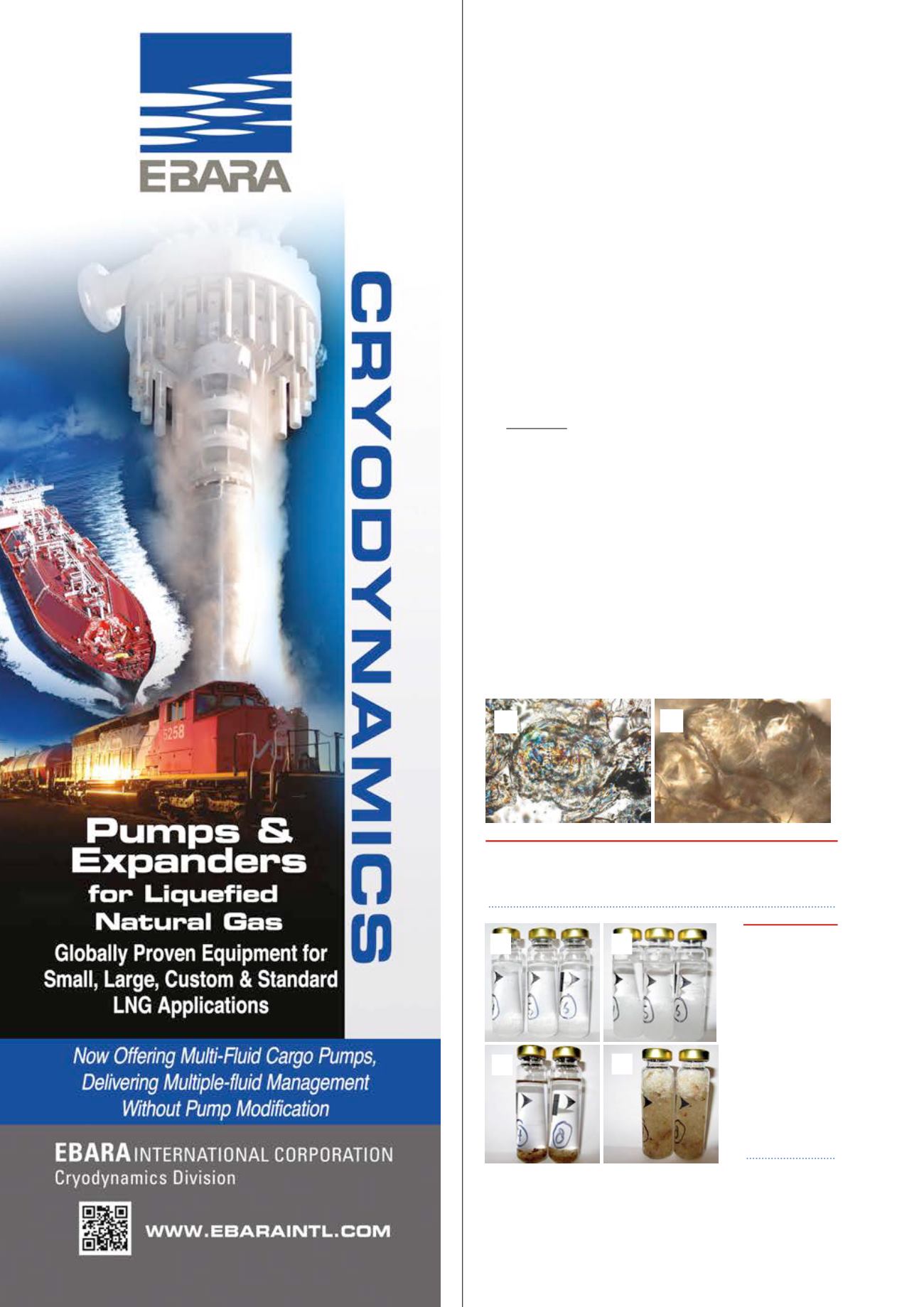

Figure 5.

Reference

popcorn

growth in

styrene, (A)

t=0 and (B)

t= 24 hrs.

Popcorn

growth of

plant sample

in styrene,

(C) t=0 and

(D) t=24 hrs.

A)

B)

C)

D)

Figure 4.

Micrographs of a representative sample

recovered from butadiene purification towers (A)

and dubutaniser reboiler (B).

A)

B)