32

December

2014

HYDROCARBON

ENGINEERING

to reduce the SRU equipment. The acid gas enrichment works very

well where the H

2

S concentration are very low, for this project, the

H

2

S concentration for high H

2

S cases varies from 46 - 68% and the

CO

2

concentration varies from 43 - 21%, corresponding from all

cases H

2

S varies between 31 - 68% and CO

2

varies between

58 - 21%.

n

n

Acid gas enrichment is very effective where the H

2

S/CO

2

ratio is

low and will achieve high CO

2

slip. The H

2

S is enriched and SRU

unit will be smaller. In this project, there was high H

2

S/CO

2

ratio

and CO

2

slip will decline, therefore the SRU will not be smaller and

the acid gas enrichment are not very effective. In other words,

after a detailed evaluation, it was concluded that adding

conventional acid gas enrichment would be not as effective as

generally expected.

n

n

Supplemental fuel gas burning: Supplemental natural gas burning is

a technique often employed to raise the flame temperature while

processing acid gas feed of low H

2

S concentrations in a sulfur

plant. However, natural gas was not available in this project, and

using fuel gas will cause soot formation.

n

n

Oxygen enrichment: Oxygen enrichment technology is an ideal

technology for raising the flame temperature of the Claus reaction

furnace especially for acid gas of low H

2

S concentration. However,

oxygen was not available in the project.

n

n

Cooling water: Using cooling water is not practical in summer due

to hot climate weather temperature; therefore, water cooler usage

in the tail gas unit would not help in summer.

Proprietary acid gas enrichment

and SRU schemes

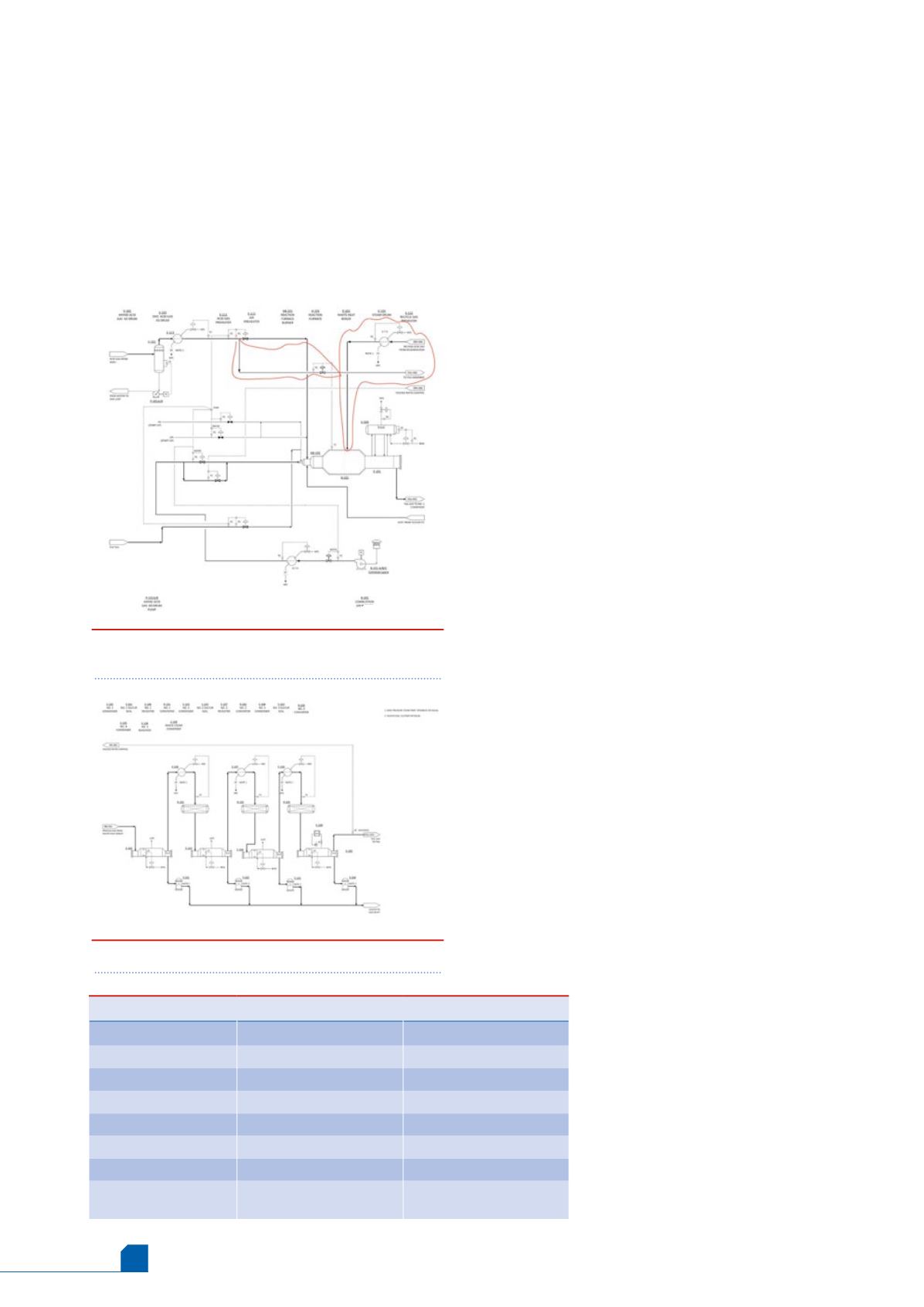

A unique acid gas enrichment process called Rich ‘S-MAX’ was

developed, and a unique proprietary scheme of the reaction furnace.

A proprietary ‘S-MAX’ two zone reaction furnace, which is different

with the conventional scheme, with high intensity burner was used. In

the conventional scheme of the two zone reaction furnace,

hydrocarbons andmercaptans will be bypassed to the second zone

where the combustion temperature would not be adequate for the

heavy impurities destruction, which will cause soot formation and

catalyst deactivation.

The combustion temperature is always higher in the first zone than

the second zone. From the above evaluation, it was concluded that we

could use exclusive schemes by RATE for the high H

2

S cases. In addition,

in order tomeet the tight stack SO

2

specification, the tail gas unit

should be designed with formulated selective solvent MDEA based

formulated solvent.

The acid gas was split from the amine unit, where up to 75% of the

amine gas entered the first zone of the reaction furnace and up to 25%

of the acid gas is routed to the tail gas absorber in addition to the

quench overhead that flows to the tail gas absorber. The tail gas amine

unit is designed with the much higher amine loading similar to the

amine unit, so in summary:

n

n

25% of the amine acid gas is sent to the tail gas absorber.

n

n

75% of the amine acid gas is sent to the first zone of the reaction

furnace.

n

n

The tail gas absorber operates at higher rich loading

(0.2 - 0.3 mol/mol).

n

n

The tail gas recycle from the tail gas regeneration unit is recycled

to the SRU but not to the first zone, instead the acid gas from the

tail gas regeneration column, which is hydrocarbon/mercaptan

free, is recycled back to the SRU. It is preheated and flows to the

second zone of the reaction furnace. The combusted gas from the

zone one reaction furnace flows to the second zone through

choke ring where the temperature is above ignition temperature,

and burn the acid gas in the second zone and the

combusted temperature leaving the reaction furnace

is 990 ˚C, according to a simulation for the high H

2

S

cases.

n

n

The tail gas absorber was designed with 0.2 to

0.3 mol/mol loading. The acid gas loading in the tail

gas absorber is normally 0.1 mol/mol maximum, and

the acid gas loading for the amine absorber is

normally 0.3 mol/mol, it means there is significant

free amine in the tail gas absorber to process the

portion of the acid gas. The tail gas absorber acts not

only as a tail gas absorber but also as an enriched

absorber without adding significant cost to the

project. This scheme also removes the

Figure 3.

Proprietary design of the reaction

furnace.

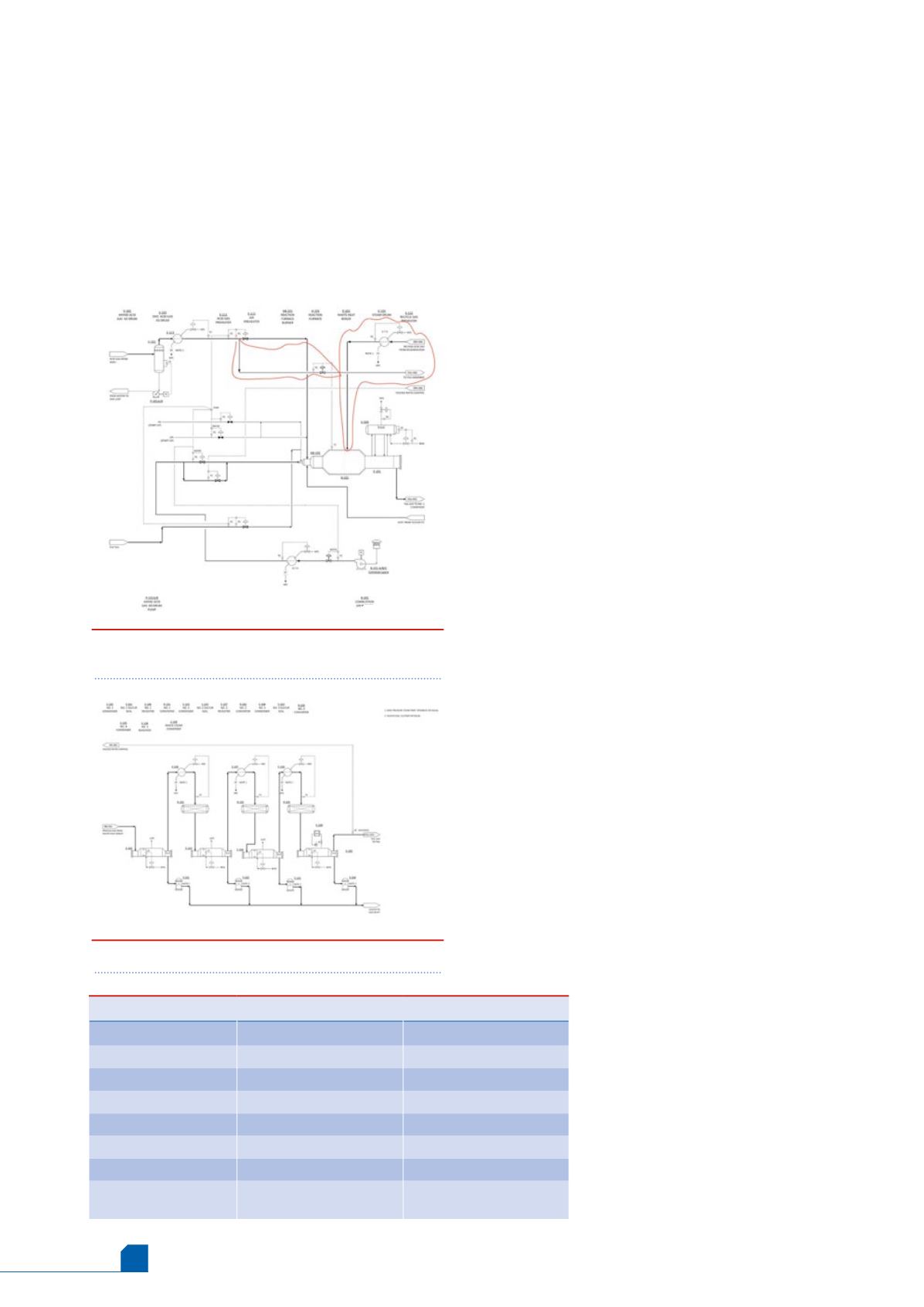

Figure 4.

Catalytic stages of the Claus unit.

Table 2.

Caustic scrubber versus conventional stack

Case

Case 1: Base case

Case 2: Alternative case

Chiller

No

Yes

Incineration type

Caustic scrubber

Stack

COS hydrolysis reactor

No

Yes

Tail gas amine circulation Lower, with higher loading Higher, lower lean loading

Recovery

99.99%

99.9%

Reliability, operability

High

Mid

Capital/operating cost

Lower (no chiller, less

power, less circulation)

Higher (chiller, more power,

more circulation)