36

December

2014

HYDROCARBON

ENGINEERING

containing catalytic cracking catalyst, which circulates

continuously from one vessel to the other through a set of

transfer lines. Those vessels are referred to as the reactor and

regenerator. The desired reaction occurs in the reactor, and over

time the surface of the catalyst particles is coated with coke, a

condensed hydrocarbon. Coke reduces the activity of the

catalyst and makes it necessary to continually remove

deactivated, or spent, catalyst to the regenerator, where the

coke is burned off in what is a very exothermic process. Once

the catalyst is cleaned, or regenerated, it is returned to the

reactor. This loop constitutes a continuous process that must

run every day, year after year, to yield maximum benefit.

FCC catalysts are typically microporous aluminosilicate

materials, and in a fluidised state, they can be quite abrasive.

Add to that high temperature and pressure, the presence of

steam, and a host of metallic and nonmetallic impurities, and

what one is faced with is an extremely difficult environment.

The impact of abrasive wear

The fluidised bed in the regenerator is maintained through the

use of compressed air, fed through a large number of nozzles

situated in one of a number of proprietary configurations. The

key element to performance in the regenerator is consistency,

and a uniform fluidisation must be maintained for maximum

regenerating efficiency. The size and shape of the orifices of the

air grid nozzles are critical to maintaining this uniformity. Any

abrasion to the nozzle has the potential to significantly impact

the geometry of the individual nozzle, and with enough damage,

eventually the overall performance of the regenerator.

When a grid nozzle wears, the shape of the flow path

through the nozzle changes, resulting in an alteration in the air

flow rate of the nozzle and, potentially, the flow pattern, as the

air flows into the bed. Distribute these changes in varying

magnitudes across the complete air grid and the resultant

variability in fluidisation and combustion can result in serious

performance issues. Catalyst regeneration rates can suffer and

reaction chemistry can change driving up catalyst deactivation

rates. Temperature distribution within the bed can change

from optimum design conditions resulting in unexpected

consequences such as HCN generation rates high enough to

carry through to flue gas discharge. The value of abrasive

wear resistance in FCCU air grid nozzles as it impacts process

consistency is significant.

Abrasion and metals

There are a number of different engineering strategies for

dealing with abrasive wear, but with regard to material

selection the generally accepted rule is the harder, the

better.

This premise can be a little tricky when it comes to metals

where in many cases resistance to abrasion is more heavily

influenced by specific constituents in alloyed compositions,

exhibiting higher individual hardness compared to the overall

average macrohardness of the composition. This characteristic

peak microhardness forms a basis for understanding abrasion

resistance in metals. Regardless, whether pure metal or alloy,

metallic compounds, as a class, are less hard than ceramic, and

because they deform under tensile stress (due to the elastic

nature of metallic bonds

1

) they are considered to be ductile

bodies; they deform, rather than fracture. Because they are

relatively soft as well as ductile, metallic material can be

displaced by erosive particles as they move across the surface.

2

This scouring effect continues for the length of the contact

between the erosive particle and the metal compound. Ergo,

the more acute the angle of impact, the longer the contact

path, and the greater the abrasive wear. The greater the angle,

the less total surface area is exposed to the effect of the

erosive particle and the less displacement occurs.

Consequently, metals wear faster at acute angles of impact

than at angles closer to 90˚. Further, metals begin to soften at

temperatures much lower than ceramic, and any excursions

can fatally undermine the material properties.

Abrasion and ceramics

Ceramics simply are harder, and this helps explain why more

often than not ceramic materials exhibit significant

advantages in wear applications. Ceramic materials,

surprisingly to some, share an important similarity to the

metallic compounds described above. They can be made

from a single ceramic constituent, or they may be ‘alloyed’ if

you will; made of multiple ceramic compounds. These

ceramic compounds do differ in one key way from metallic

alloys, the bond phase.

There are a number of grades of ceramic materials,

including structural, technical, refractory, and white ware.

Technical ceramics include tiles used in the Space

Shuttle program, gas burner nozzles, ballistic protection,

biomedical implants, jet engine turbine blades and missile

nose cones. Refractory ceramics include such things as kiln

linings, steel and glass making crucibles, and various

monolithic, or unformed, compositions used in the

petrochemical industry.

When one thinks of hard, abrasion resistant ceramic

materials, one is generally thinking of a technical ceramic,

with a fine grained, fully dense, sintered body. This is

analogous to the pure metallic composition described above.

The hardness of the single constituent dictates the abrasion

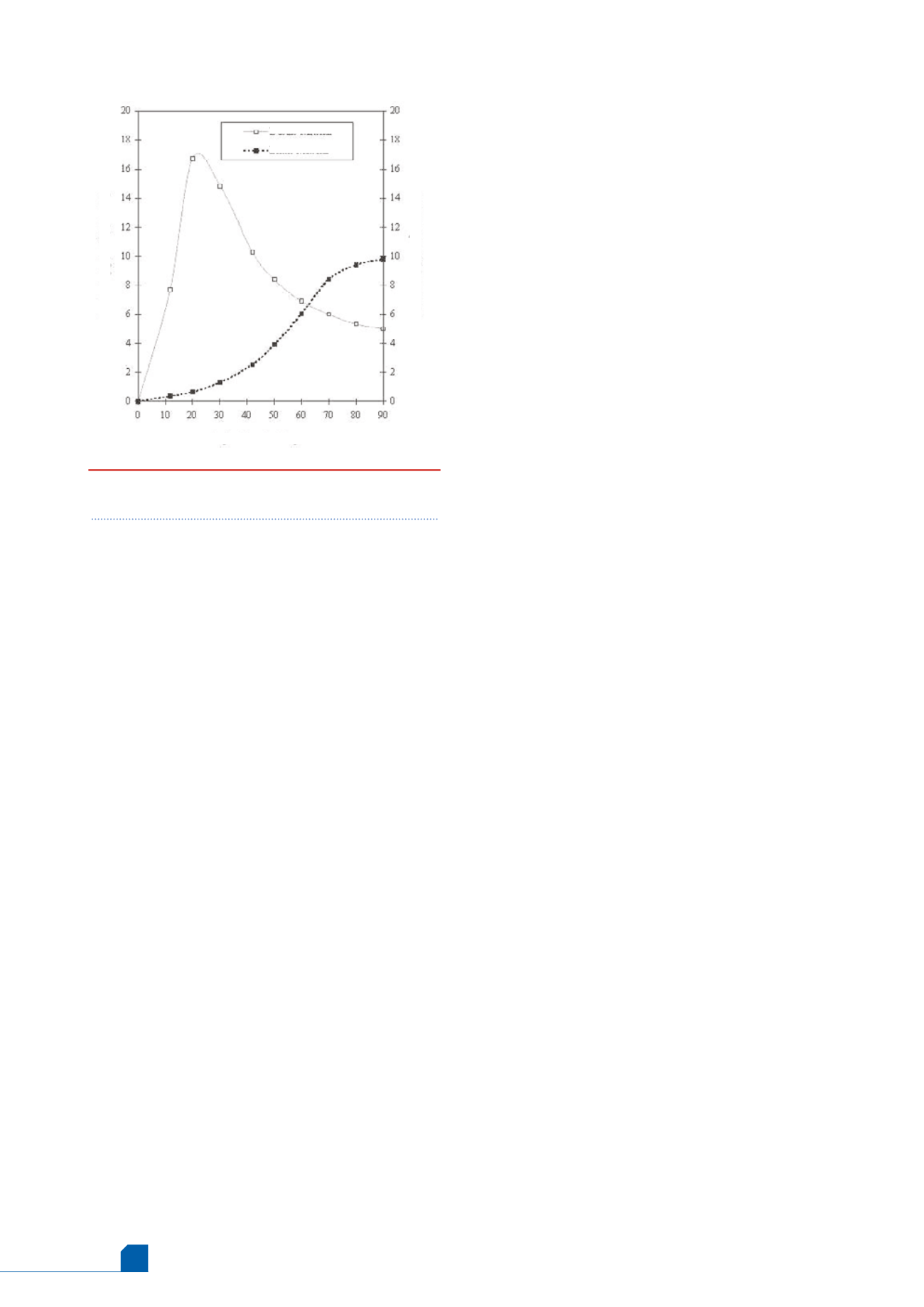

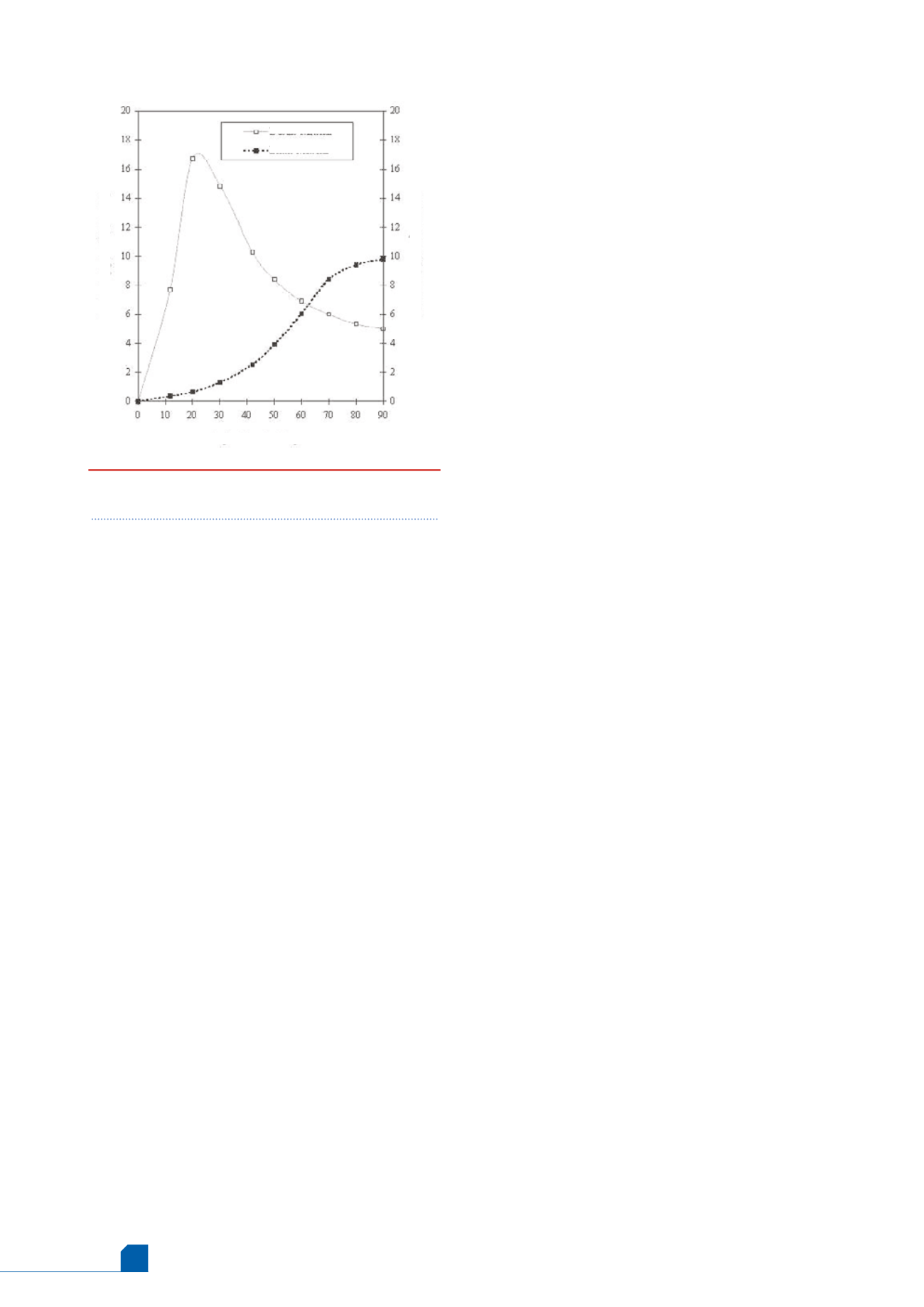

Figure 1.

Erosion resistance of ductile versus

brittle materials.

3

off the harder ceramic particles. As the angle of impact approaches 90 degrees, erosive particles can

hammer away at the typically softer bond phase, and begin displacing harder ceramic particles that way.

It is worth noting that the angle of incidence between erosive particles and the exposed surface of the

nozzles is generally acute, as the flow of air and particles swirls across the tips of the nozzles.

Figure 1. Erosion Resistance of Ductile vs. Brittle Materials

3

It wasn’t until the late 1980’s that a few plants started using ceramic for the air grid nozzles. They saw

the benefit of the monolithic castable materials used in areas covering the grid and in the cyclone.

Requirements for length of campaigns have been increasing, along with temperatures and pressures,

and it became imperative to find a material that would be up to the task. Over the last 20+ years a wide

variety of alloys, weld overlays, and ceramic materials have been tried in grid nozzles, with varying

results. The bulk of the ceramic materials have been fully dense technical ceramics, selected purely for

their abrasion resistanc . N t surprisingly, most of these suffered from early failure du to thermal

shock.

3

COMPUTATIONAL MODEL OF DUCTILE EROSION BY SINGLE PARTICLE IMPACT, Chandrakant Rai, West Virginia

University, Morgant wn, WV, 2000

Erosion in g/g ( x 10 ) [Ductile]

Ductile Material

Brittle Material

Angle of Attack in degrees

Erosion in g/g ( x 10 ) [Brittle]