In order to proceed to performance evaluation,

IPC applied this method in the following steps:

n

Expected performances related to design inlet

conditions have been adjusted to field suction

conditions.

n

Field performances are compared to adjusted

expected performances.

At this point it is possible to proceed with the

comparison.

Software

In order to use Cmap, the starting point is the

availability of a compressor performance map, the

relevant gas mix composition and thermodynamic

conditions (pressure and temperature). Having this

input data available, the software will perform all

complex calculations fully and produce expected

compressor performance details.

The input process offers a number of alternative

methods of entry. The most common method is to

enter performance curves expressed in terms of

delivery pressure versus inlet flow rate, and delivery

temperature versus inlet flow rate. Data input

processes can also be executed in a digital way,

picking up graphical data directly from pdf or jpeg

files.

Cmap is structured to allow analysts and

engineers to build their own machinery database and

maintain the records of all executed calculations.

Case study

The compressor under study was mapped for two

different inlet conditions of pressure and

temperature:

Design condition 1 (D1)

Pressure: 40.2 bar.

Temperature: 50 ˚C.

Design condition 2 (D2)

Pressure: 53.2 bar.

Temperature: 37.8 ˚C.

Starting from the curves of the D1 condition, the

expected performance curves in the D2 were

calculated using the Cmap software. The obtained

curves, D2calc, were then compared to the D2 curves

available as input.

Figure 3 compares the D2calc with the D2

performance curves. The curves almost overlap: the

maximum error calculated is less than 0.2%

(polytropic work at maximum speed). Measured

errors have been considered tolerable for the

purpose of the evaluation of compressor field

performance.

This case study confirms the capability of the

proposed method to predict compressor

performances aligned with design ones. An important

application of these proposed methods is on surge

protection systems and for diagnostic purposes.

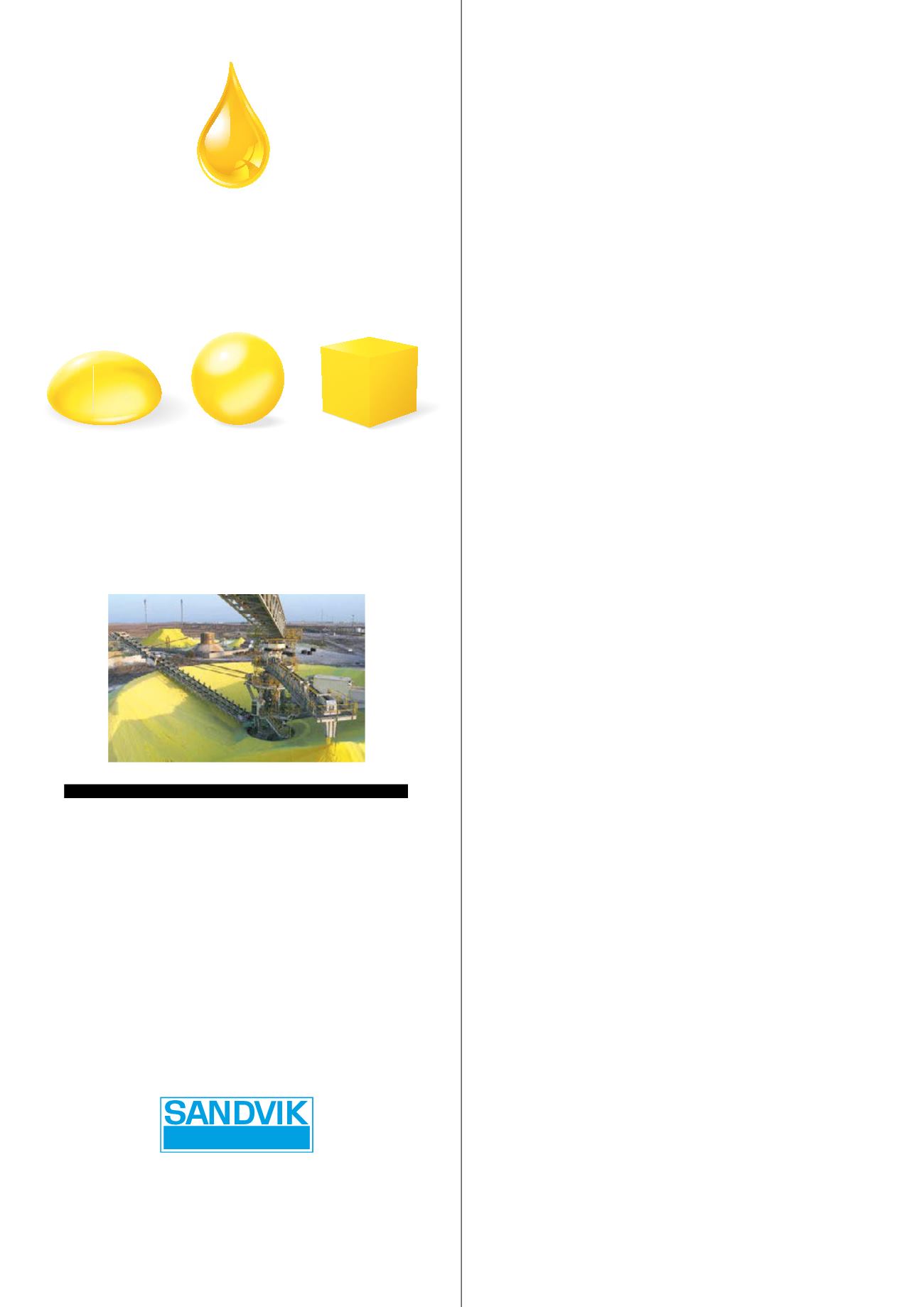

Sandvik sulphur

solidification solutions

Our acquisition of the technology and know-how of the

Brimrock Group means we now offer a full range of

solidification solutions, from our proven Rotoform

pastillation process and Brimrock RS1500™ granulation

to complete block pouring and forming facilities. No

wonder we’re known as The Sulphur Company.

n

Rotoform granulation for premium quality

and small/mid-size capacity

n

Fully automated Brimrock RS1500™

for fast, reliable high capacity granulation

n

Block pouring for cost effective long term storage

n

End-to-end process capability – from receipt of liquid

sulphur to storage, handling and loading

It’s what we do.

Sandvik Process Systems

Division of Sandvik Materials Technology Deutschland GmbH

Salierstr. 35, 70736 Fellbach, Germany

Tel: +49 711 5105-0 · Fax: +49 711 5105-152 ·