3

Paper for Oil&Field

2

Final review

1

Preliminary review

Tech. report.20/11

0

Prediction of centrifugal

compressor performances

Paganini Di Febo 13/05/2014

E

9/9

rev

description

prepared checked approved date

language sheets

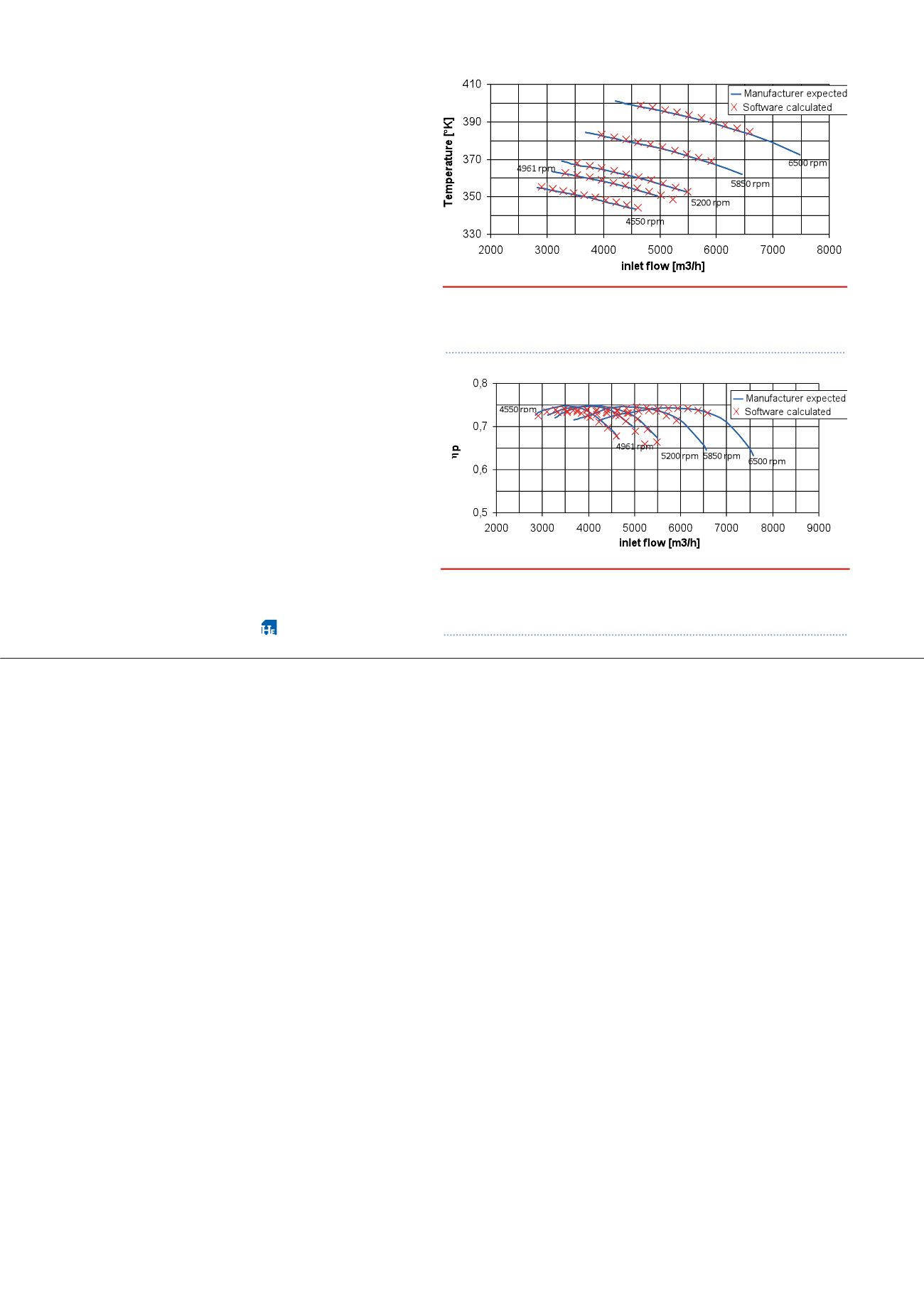

figure 4

figure 5

Figure 4.

Centrifugal compressor design performances

comparison to calculated performances (discharge

temperature).

Project : Pro 250 - CMap

PREDICTION OF CENTRIFUGAL

COMPRESSORS PERFORMANCES

AND APPLICATIONS FOR TEST,

SURGE PROTECTION AND

MACHINERY DIAGNOSTIC

TR 20/11 Paper Cmap rev 3

3

Paper for Oil&Field

2

Final review

1

Preliminary review

Tech. report.20/11

0

Prediction of centrifugal

compressor performances

Paganini Di Febo 13/05/2014

E

10/10

rev

description

prepared checked approved date

language sheets

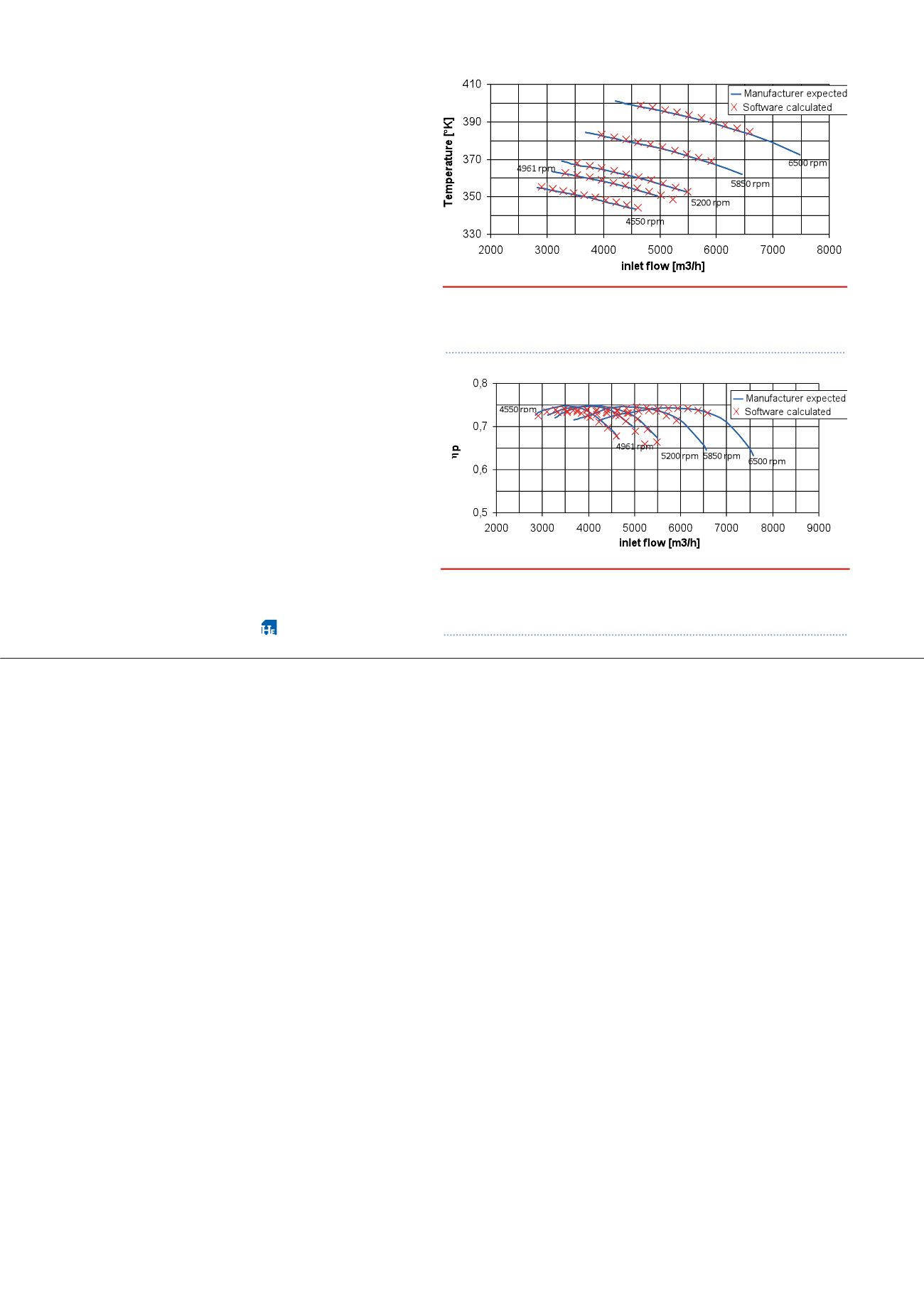

figure 6

In the previous pictures it can be noted how the curves almost overlap: the maximum error

calculated is less than 0.2 % (polytropic work at maximum speed). Measured errors have

been considered tolerable for the purpose of the evaluation of compressor field

performance.

This case study confirms the capability of the proposed method to predict compressor

performances aligned with design ones.

An important application of these proposed methods is on surge protection systems and

on diagnostic purposes

The actual centrifugal compressors protection systems are based on simplified algorithms

that use basically the inlet flow, suction and discharge pressures and temperatures. These

actual algorithms, are based on a basic surge locus equation obtained under simplified

hypothesis such as the ideal gas law, validity of hydraulic affinity laws, reference gas mix

and inlet conditions. These algorithms are consequently completly dependent on the

suction thermodynamic parameters (pressure, temperature and gas mix composition): the

protection action is than rigidly linked to design suction parameters and remains valid only

for the design specified gas mix. Therefore these systems provide a limited surge

protection valid in a small operative range around the design conditions. The compressor

protection is not correctly active when inlet conditions move to off design values, especially

when approaching the high pressures range where introduced errors do not allow to

provide enough accurate predictions for more severe applications

Figure 5.

Centrifugal compressor design performances

comparison to calculated performances (polytropic

efficiency).

Actual centrifugal compressor protection systems

being reliant on simplified algorithms that use suction

thermodynamic parameters, the protection action is

rigidly linked to design suction parameters and remains

valid only for the design specified gas mix. Therefore,

these systems provide a limited surge protection valid

in a small operating range around the design conditions.

The compressor protection is not correctly active when

inlet conditions move to off design values, especially

when approaching high pressure range.

Conclusion

The methods proposed and described in this article can

allow operators to:

n

Predict the performances of a centrifugal

compressor under varying thermodynamic

conditions of the inlet gas. The prediction of

compressor performances is accurate even at high

pressures, where the ideal gas theory commonly

used introduces considerable errors.

n

Analyse the performance of the compressor during

operation and compare them with those expected

(provided by the manufacturer).

n

Implement advanced protection from surge,

overcoming limits of the current technology.

n

Having useful indications of the health of the

compressor (diagnostics) based on the capability to

analyse the performances and efficiency of the

machine in a simple and immediate way.

n

Support decisions and planning of predictive

maintenance and activities.

REMBE

®

GMBH · SAFETY + CONTROL ·

Gallbergweg 21 · 59929 Brilon / Germany

T + 49 (0) 29 61 - 74 05 - 0 · F + 49 (0) 29 61 - 5 07 14 ·

✸✸✸

✸✸✸

Quickest

Response-

and Lead

Times

Bursting Discs

and Breather Valves

BURSTING DISCS

MADE IN GERMANY

All rights reserved - © REMBE - BDBV3-4C-E