significant reduction in the number of

main headings, which causes the static

pressure of primary escapeway to peak

in this area. It is possible to see that the

general pressure gradient trend of the

segregated belt road is flatter than that

of the primary escapeway, causing the

belt road to be at a higher static

pressure than the primary escapeway.

This results in the leakage of

contaminant into the primary

escapeway in the event of a belt fire.

This scenario had 17 vehicle doors

positioned along the trunk belt system.

This highlights the need for vehicle

and personnel access to the belt road

and subsequent issues with quality of

stoppings and leakage.

Case 2

Case 2 is based on a longwall mine in

the Bowen Basin in Queensland,

Australia. The trunk conveyor of the

mine is generally segregated on both

sides from the surrounding intakes

with 106 segregation stoppings. The

primary escapeway of the mine is

the main travel road.

This scenario involved the most

elaborate layout for segregation of

the belt road of all the scenarios

analysed. Table 1 shows that the

contaminant result for the longwall

face is 53 ppm regardless of whether

the segregation stoppings are in

place or not. The mains development

panel showed a reduction of 15 ppm

to 1 ppm with the removal of the

segregation stoppings and another

development panel showed a rise

from 1 ppm to 7 ppm. The primary

escapeway, however, showed a

significant increase from 6 ppm to

31 ppm with the removal of the

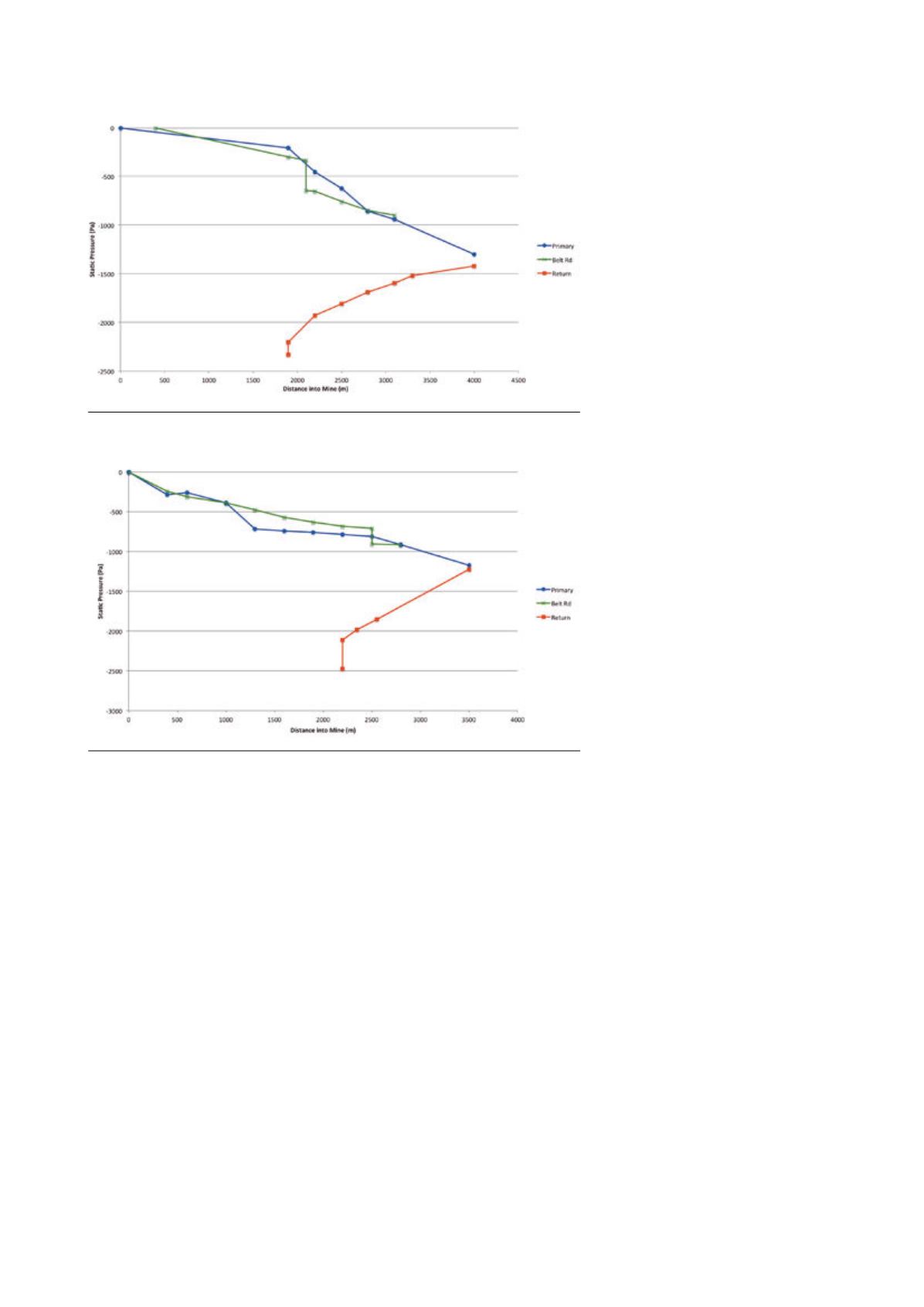

segregation stoppings. The pressure

gradient plot for Case 2 shown in

Figure 4 shows the extent that this

particular operation has gone to get

the pressure in the belt road to below

the pressure in the primary

escapeway (travel road).

The step in the pressure gradient

for the belt road at the 2000 m mark

is due to the placement of a

regulator and an air dump in the belt

road. This does a good job reducing

the pressure of the belt road and

largely prevents leakage of the

contaminant into the primary

escapeway. The infrequent instances

when the belt road has a higher

static pressure than the adjacent

primary escapeway results in the

low result of 6 ppm. The air dump

directs air out of the belt road into

adjacent intake roadways. It is this

air that is directed to the longwall

– and this is the reason for the

53 ppm result for the longwall face.

Case 3

Case 3 is based on a longwall mine

in the Bowen Basin in Queensland,

Australia. The trunk conveyor of the

mine is generally segregated on both

sides from the surrounding intakes

with 64 segregation stoppings. The

primary escapeway of the mine is a

roadway separate from the main

travel road and on the other side of

the trunk conveyor.

This scenario initially showed the

most promise for having a simple

design and maintaining a primary

escapeway at a pressure above the

adjacent belt road. However, the

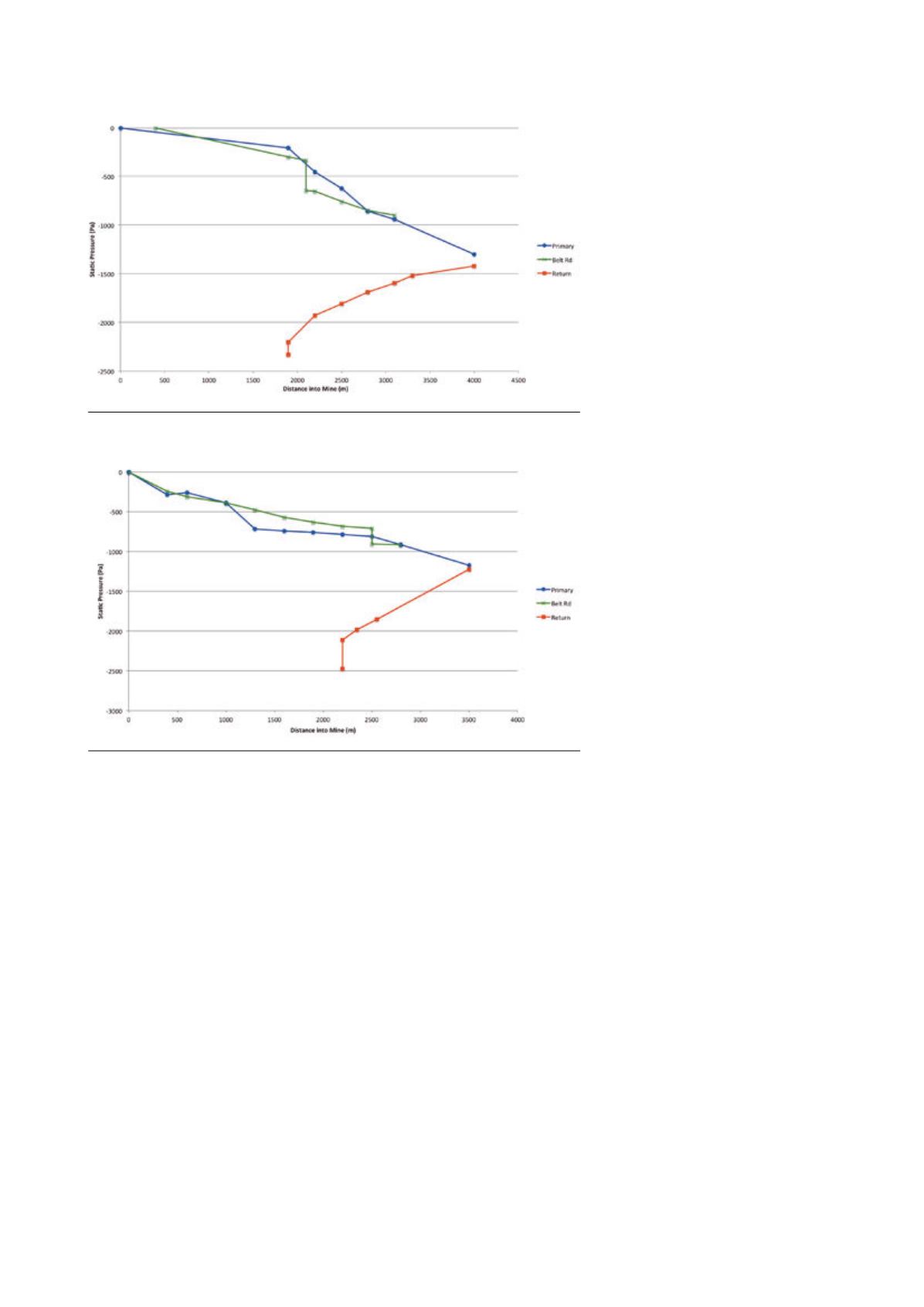

pressure gradient plot in Figure 5

shows that this is not the case. The

belt road is generally at a greater

static pressure than the adjacent

primary escapeway. This is reflected

in the results in Table 1, with

arguably better results achieved with

the segregation stoppings

removed from the model. The

primary escapeway showed an

increase in contaminant

concentration from 26 ppm to

29 ppm with the segregation

stoppings removed.

There are two ways this scenario

could be dramatically improved. The

50

|

World Coal

|

September 2014

Figure 4.

Case 2: pressure plot.

Figure 5.

Case 3: pressure plot.