mine consists of seven heading

mains, three headings with flanking

returns and a segregated belt road in

the middle heading. As the mine does

not exist, there is not a designated

primary escapeway.

There are two results for the

contaminant test for the primary

escapeway shown in Table 1,

depending on which set of intake

roadways is adopted as the primary

escapeway. The results show that,

with the 157 segregation stoppings in

place, the contaminant is directed

predominantly into the mains

development area with a

concentration of 76 ppm. The other

three panels (including LW) modelled

a contamination around 15 ppm. The

greatest benefit modelled with this

arrangement of segregation was the

contaminant concentration of 4 ppm

adjacent to the 76 ppm in the mains.

The 4 ppm result came from the

single intake airway to the left of the

middle heading belt road in Figure 1.

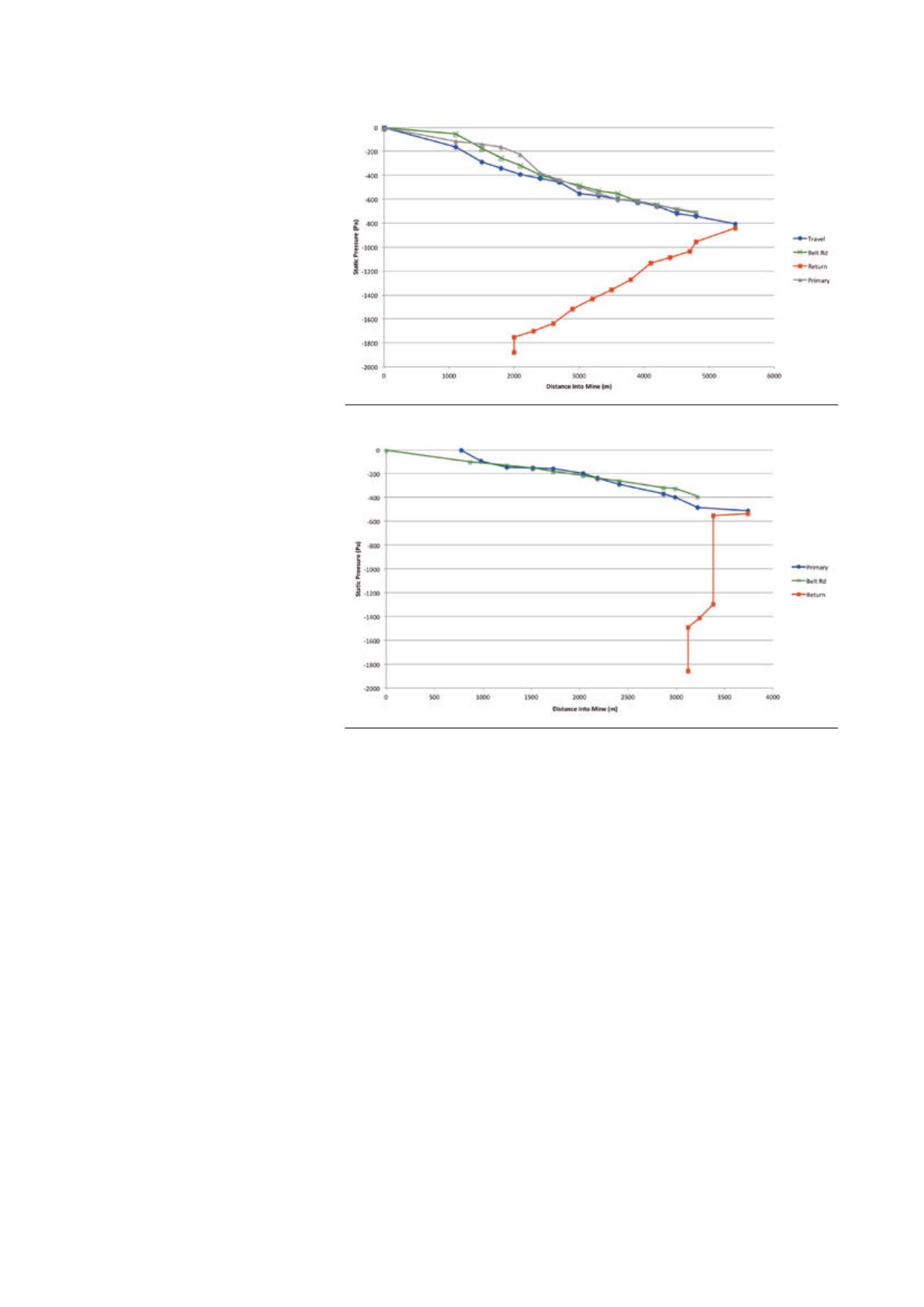

The reason for the relatively low

level of contamination can be seen in

the pressure gradient plot for Case 0

in Figure 2. The heading that

returned the result of 4 ppm is

referred to in Figure 2 as primary.

This heading for the most part sat at a

higher static pressure than the

surrounding roads, particularly the

belt road where the contaminant was

concentrated. This resulted in leakage

paths flowing away from this

primary heading. The instances

where the static pressure in this

roadway drops below the belt road is

due to the placement of segregated

belt underpasses that were put into

the model to allow for transport

movements (operational requirement)

and balancing of the intake airway

pressures. This balancing caused the

drop in static pressure to below

that of the belt road in some

instances. This could be mitigated in

practice via the installation of

machine doors at the segregated

underpasses.

The results in Table 1 also show

that by removing all segregation from

the model, all inbye areas of the mine

received similar contaminant

concentrations of around 30 ppm.

This includes all working faces

and escapeways.

Case 1

Case 1 is based on a longwall mine in

the Bowen Basin in Queensland,

Australia. The trunk conveyor of the

mine is segregated on both sides from

the surrounding intakes with

203 segregation stoppings. The

primary escapeway of the mine is the

main travel road.

The contaminant test in Table 1

shows some very interesting and

unexpected results. The highest

contaminant results with the

segregation stoppings in place were

31 ppm in the primary escapeway,

30 ppm in the mains development

panel and 25 ppm in one of the

gateroads. Without the segregation

stoppings in place, the most

significant result was the reduction of

contaminant in the primary

escapeway by 30% down to 22 ppm.

The longwall result increased from

7 ppm to 17 ppm without the

segregation stoppings in place, while

the mains development and one of

the gateroads both had reductions in

the level of contaminant. As expected,

the contaminant was more spread out

and diluted without the segregation

stoppings and more concentrated in

particular areas.

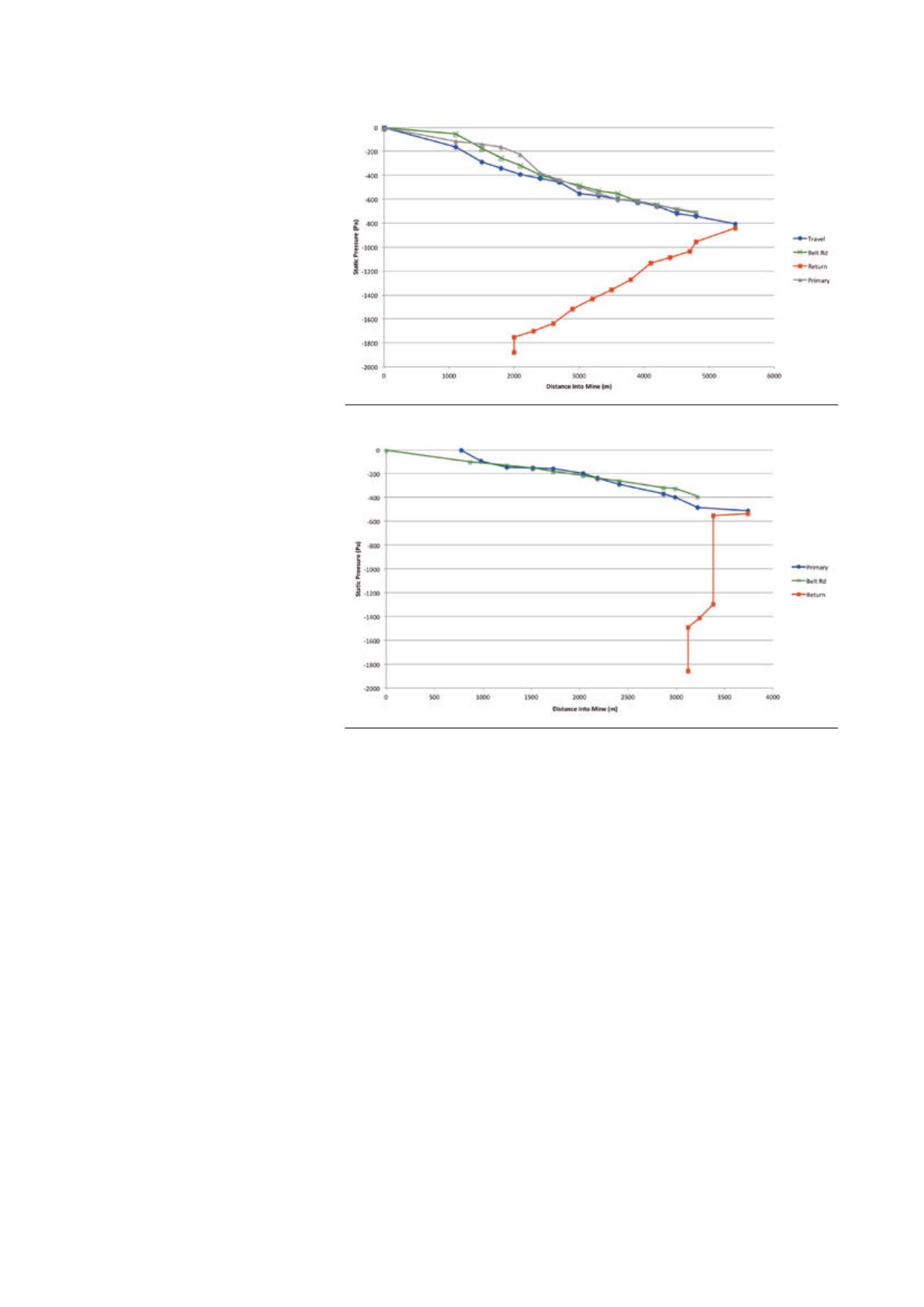

The pressure gradient plot for

Case 1 in Figure 3 shows the belt

road at a higher pressure than the

primary escapeway most of the time.

The first 1000 m the primary

escapeway and the belt are in

separate drifts so the leakage would

be almost non-existent. The time

where the primary escapeway sits

above the belt road in static pressure

around the 2000 m mark is due to a

September 2014

|

World Coal

|

49

Figure 2.

Case 0: pressure plot.

Figure 3.

Case 1: pressure plot.