although the flame is still considered to

have been stopped on the spot.

Tests 1 and 7 were baseline

explosion tests with coal dust placed

outbye of the methane chamber. In

these tests no suppression system was

placed in the tunnel; they were done to

determine flame propagation speeds

and maximum flame travel. In these

tests the coal dust explosion flames

propagated beyond the final

sensor positions at 81 m and

reached maximum speeds of

306.8 – 366.3 m/sec at the 41 m

sensor position.

In the tests with a single

suppression system installed at 5 and

7 m and a double system at 7 m and

12 m respectively, it was clear that the

methane ignition was inhibited to such

an extent that no coal dust participated

outbye of the barrier position.

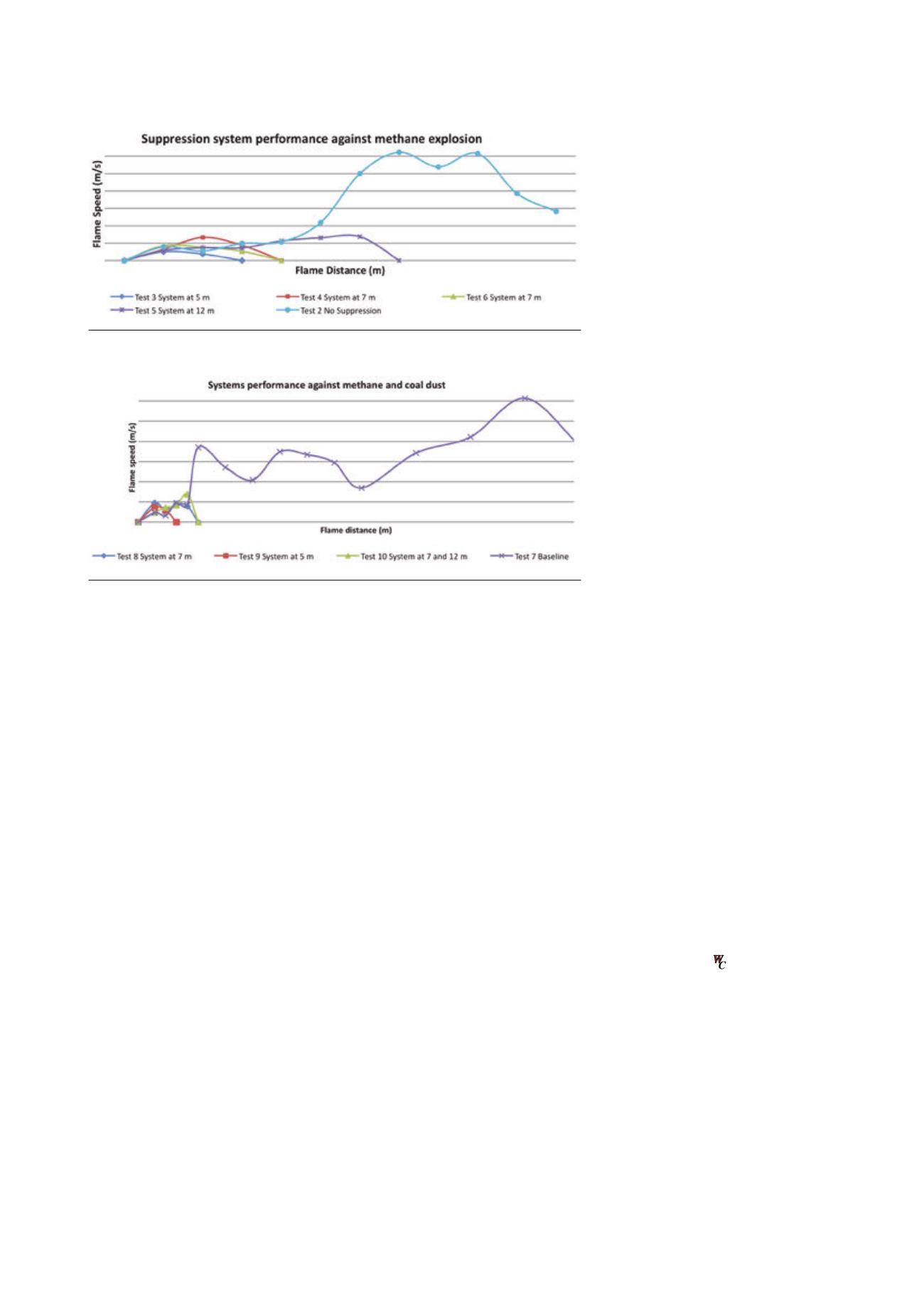

The average flame speed for the

baseline and for the flame inhibition

by the active barrier system when

installed at 5 m, 7 m and at 7 and 12 m

is shown in Figure 4.

In all the tests, the system was

successful in suppressing flame

propagation. In each case the

performance of the system can be

classified as stopped on the spot, i.e. the

flame was stopped at the position at

which the systemwas placed. The active

barrier successfully suppressed

propagating coal dust flames

approaching the barrier at flame speeds

varying from 24.4 – 62.2 m/sec.

In the unsuppressed explosion, the

flame front reaches a distance of 180 m

within 750 msec, while the flame front,

with the system installed at 30 m from

the end of the tunnel, does not reach

50 m.

The test results in the 200 m

Kloppersbos tunnel were extrapolated

to design the active suppression

protection system for longwall

mining. The 200 m tunnel provides a

means of conducting large-scale

evaluations and assessments of

barrier performance and other

requirements that cannot be done

economically by other means.

Deployment of systems

A total of 17 machine-mounted systems

have been deployed in SouthAfrica at

Sasol mines andAnglo Thermal Coal

operations. The system has successfully

suppressed methane gas ignitions on five

separate occasions.

In China, more than 400 systems have

been deployed. The system is utilised

within longwall operations to protect

against ignitions associated with shearer

frictional events. It is also deployed as a

roadway barrier within 30 m of the

tailgate position. Recent legislative

changes in China have resulted in it

being made mandatory to install

ExploSpot systems on roadheaders and

to install roadway barriers in all returns

in Shanxi Province and

Liaoning Province.

Conclusions

In protecting a mine against methane

and/or coal dust explosions, many

different controls are implemented.

However, many of these controls

remain under the control of man. In

this context, the use of active barrier

systems can assist mine management

in the prevention and control of the

risk associated with mine explosions.

The results obtained in the 10 m,

20 m and 200 m test tunnels at

Kloppersbos still need to be

considered in terms of the constraints

of the different tunnels and different

evaluation protocols. Nevertheless,

from the tests conducted, it can be

concluded that the ExploSpot system

was successful in stopping methane

explosions and the associated flame

propagation when ammonium

phosphate powder was used as the

suppression material.

In all the tests conducted, both

methane explosions and methane and

coal dust hybrid explosions, the

ExploSpot system stopped the flame

spread, thus successfully preventing

coal dust from participating in the

methane ignition.

Note

This article is based on a presentation given

at the Coal Operators’ Conference 2014,

12 – 14 February 2014, Wollongong, Australia.

References

For a complete list of references see:

DU PLESSIS, J.J.L. and SPÄTH, H., “Active

barrier performance preventing methane

explosion propagation”, in AZIZ, N.

et al

(eds.),

Proceedings of the 2014 Coal Operators'

Conference

(University of Wollongong; 2014).

Available at:

.

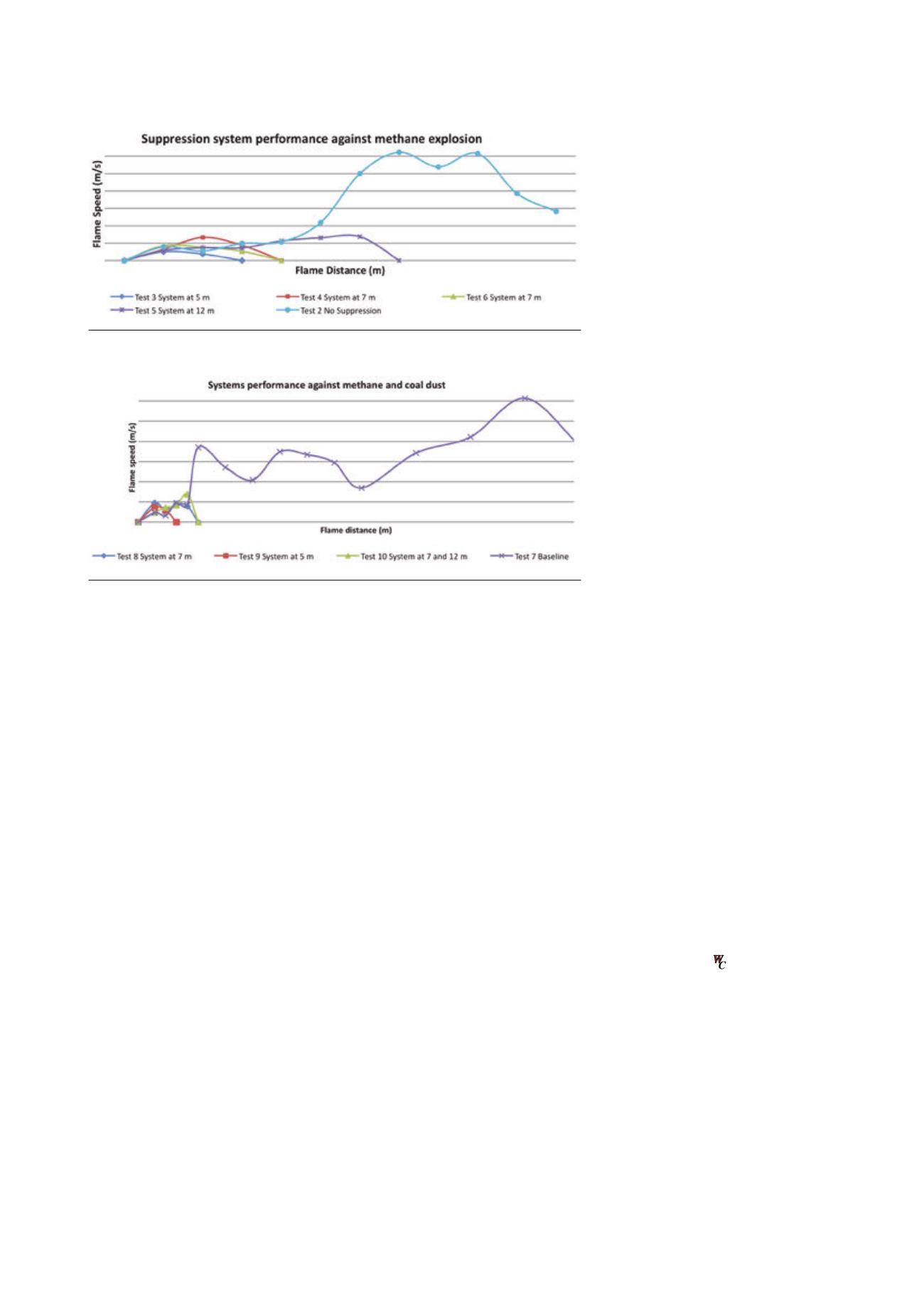

Figure 3.

Test 2 (baseline) flame and performance of the active barrier.

Figure 4.

Tests 8, 9, 10 and 7 average (baseline) flame speed and active barrier

performance.

46

|

World Coal

|

September 2014