mining application, the active

suppression system can only be

mounted on the auger outside the

production hole, thus far away from

the cutter head. As the cutter head is

most likely to be the only ignition

source and the auger hole the only

roadway for the ignition to propagate

in, it can be expected that the explosion

would exit the auger hole in due

course. This is, however, dependent on

the amount of fuel and oxygen

available and on the amount of

confinement achieved by the number

of auger flights trailing the cutter head.

The Kloppersbos explosion tunnel is

10 m long, with a 2 m dia. It is raised

700 mm above a cement floor with one

side sealed off by a steel plate. During

a suppressed explosion, the steel plate

acts as an emergency pressure-release

mechanism in the event of very high

pressures building up in the tunnel.

In one test a fuse cap was used to

ignite the methane/air mixture. In all

the other tests, a shielded detonator

was used to ignite the flammable gas

mixture. The fuse cap was initially

chosen for use because it produced a

flame that would not be seen or

recognised by the triggering

mechanism of the suppression system.

The detonator was shielded from

the triggering system; the reason for

using it was to create a more violent

methane explosion. The chamber

containing 23 m

3

of methane/air

mixture was obtained by placing a

plastic membrane 7 m from the closed

end of the tunnel. This amount of

methane/air mixture will produce

enough wind pressure to lift the coal

dust into the air, supply sufficient heat

to the coal dust particles for flame

propagation to take place and be

sufficient to ensure flame growth up to

5 m beyond the tunnel mouth.

For most of the active suppression

system tests conducted in the 10 m test

tunnel, an explosion mixture of 9%

methane/air per volume was used.

This was done to test the triggered

barrier system under simulated

worst-case scenarios. A small amount

of coal dust was placed on racks at the

open end of the 10 m tunnel.

The measure of success was defined

to indicate whether the flame

propagation was stopped inside the

tunnel opening (referred to as

“stopped inside”). The results of the

methane explosion tests are shown in

Table 1.

In every test, the flame was

stopped at the tunnel opening, with no

flame visible from the front and

perpendicular to the tunnel. Each

explosion was further captured on

camera and a record of the photos

and the video material was used to

evaluate the success of the flame

suppression.

The ExploSpot system registered a

methane ignition and opened the

extinguishing cylinders within 20 msec.

The suppressing agent sealed off the

tunnel opening completely within

30 msec, preventing the flame from

penetrating the suppressant material.

During these tests the suppressing agent

was initially dispersed at high pressure

(stored at 60 MPa in the cylinder) and

velocity into the propagating flame

front. From the tests conducted, it was

concluded that the auger

machine‑mounted ExploSpot system

was successful in stopping a methane

flame in the tunnel opening.

20 m test tunnel

A 20 m test tunnel was erected at the

Kloppersbos Research Facility to suit

the double-pass mining method

associated with the use of a continuous

miner. The tunnel was modified to

simulate the dimensions of mine

workings of medium seam height. A

full-scale model of the Joy 12HM9

continuous miner was used for test

purposes. The test tunnel is 20 m long

and 7 m wide, with a variable height of

2 – 6 m. It has a cement floor and

springs along both sides, on the outside,

supporting and guiding it. For the case

of an unsuppressed explosion, the

tunnel is able to lift up to 140 mm off its

base to provide an alternative escape

route for the expanding gases. For the

full-face conditions, the cross-sectional

area was approximately 21 m

2

.

The test sequence was carried out in

order of ascending difficulty. Three

main placements of the machine inside

the tunnel were tested, as well as

sub-conditions for the placements of the

boom (and thus ignition) and, of course,

the various methane concentrations.

The testing began with the 9%

methane/air explosion for full-face

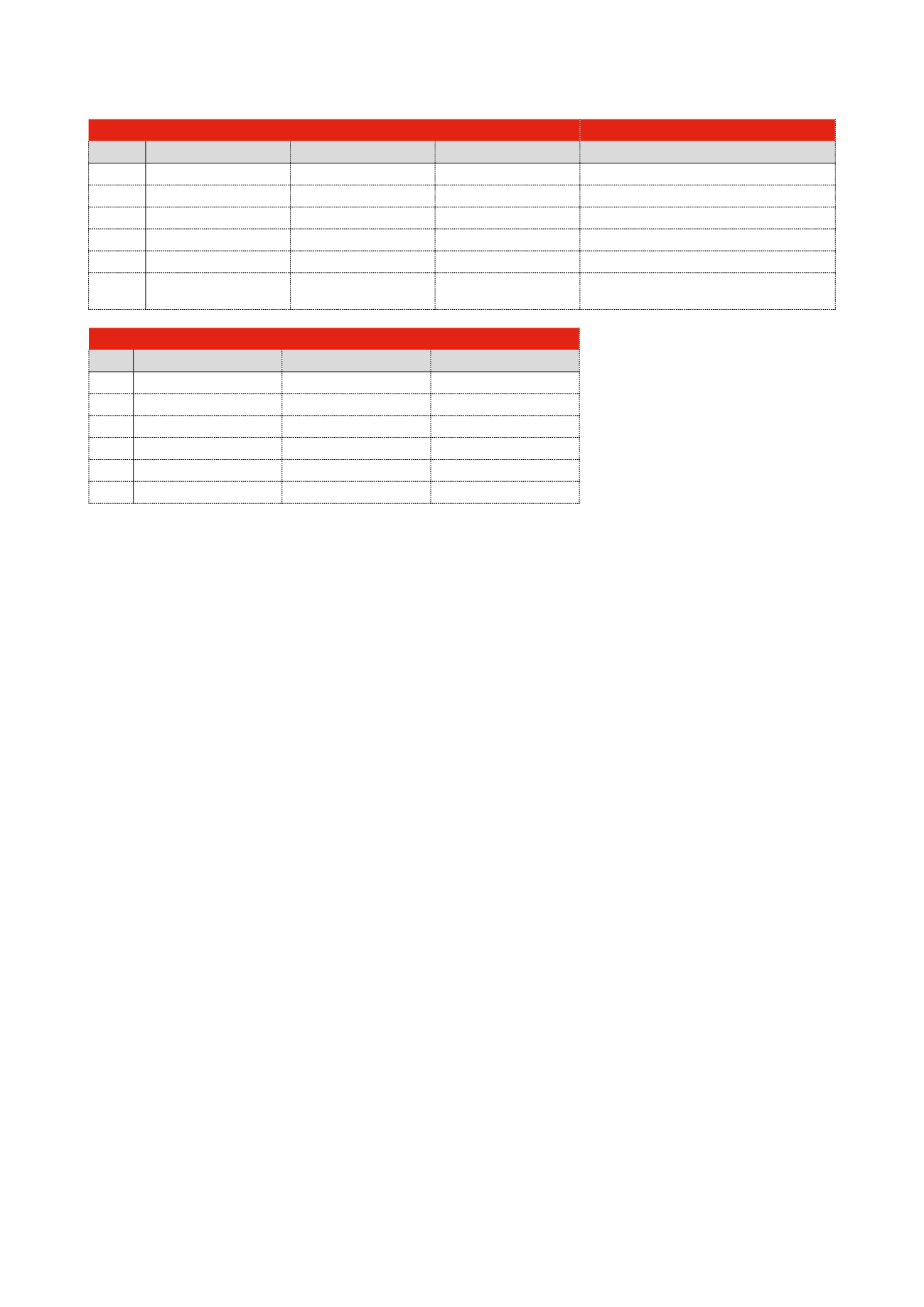

Table 1: Results of the performance of the ExploSpot system

Test

Methane concentration (%) Initiator used

Visible flame

Comments

1

7.5

Detonator

None

One cylinder failed, flame stopped successfully

2

9

Detonator

None

Flame stopped successfully

3

9

Detonator

None

Flame stopped successfully

4

9

Fuse cap

None

Flame stopped successfully

5

12

Detonator

None

Flame stopped successfully

6

9

Detonator

None

Flame stopped successfully. Small flame could

be seen at the back of the tunnel.

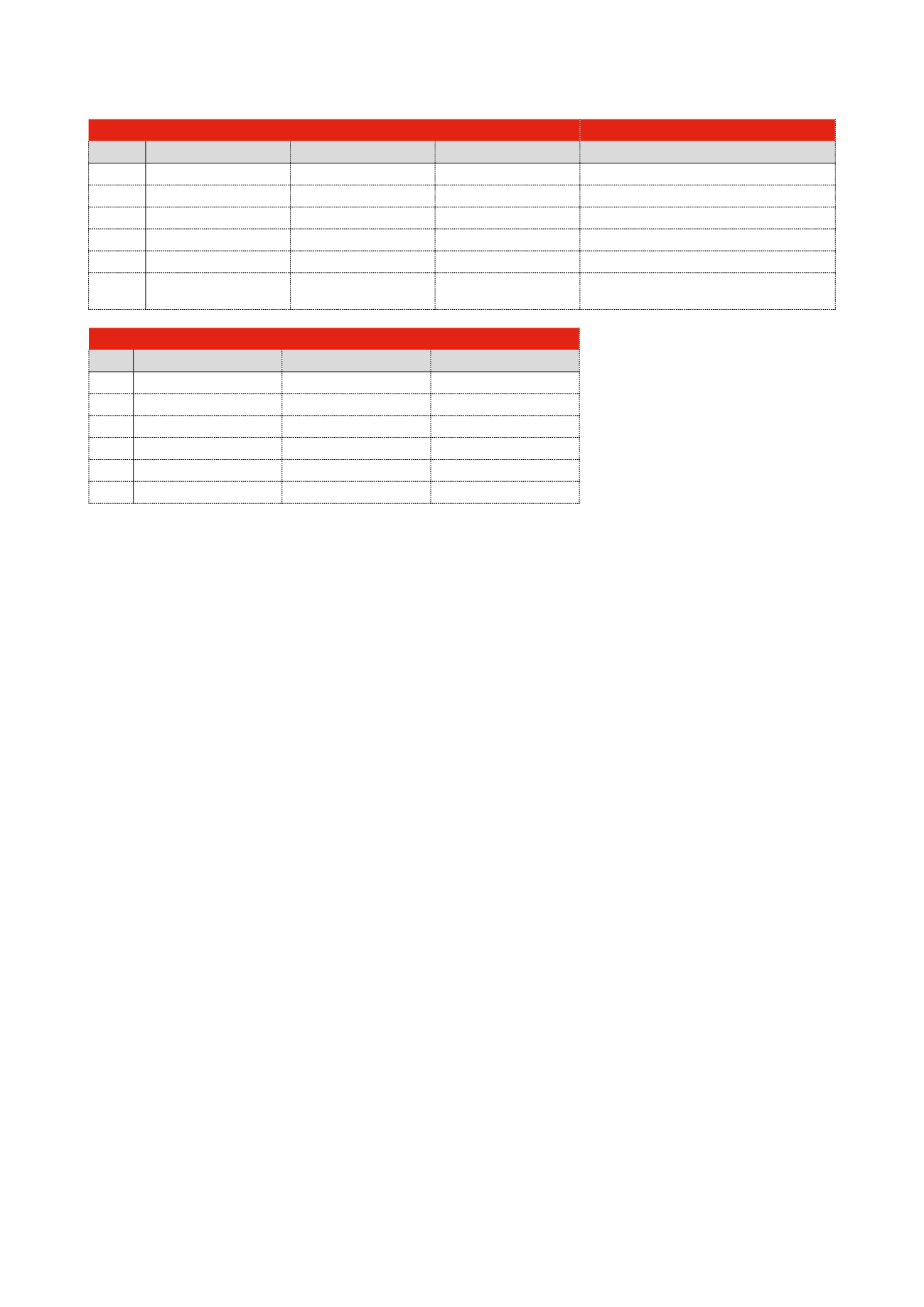

Table 2: Full-face active suppression test results

Test

Methane concentration (%) Flame length (m)

Temperature increase (˚C)

77

9

6

80

78

9

6

no temperature rise

79

9

6

93

80

9

6

70

81

9

6

no temperature rise

82

12

5

58

44

|

World Coal

|

September 2014