appropriate gear for the movement.

Focus can instead be directed on

carefully manoeuvring the truck

across the difficult terrain in a safe

manner. This not only reduces the

stress that a driver endures when

operating a fully loaded truck in

desert conditions, but also lowers

the need for any advanced training,

as the automatic gearboxes are easy

to operate. This ease-of-use also has

the advantages of helping eliminate

bad driving habits, as the correct

gear is always selected, cutting out

incidences of over-revving the

engine and grinding gears, thus

reducing both engine and

transmission wear.

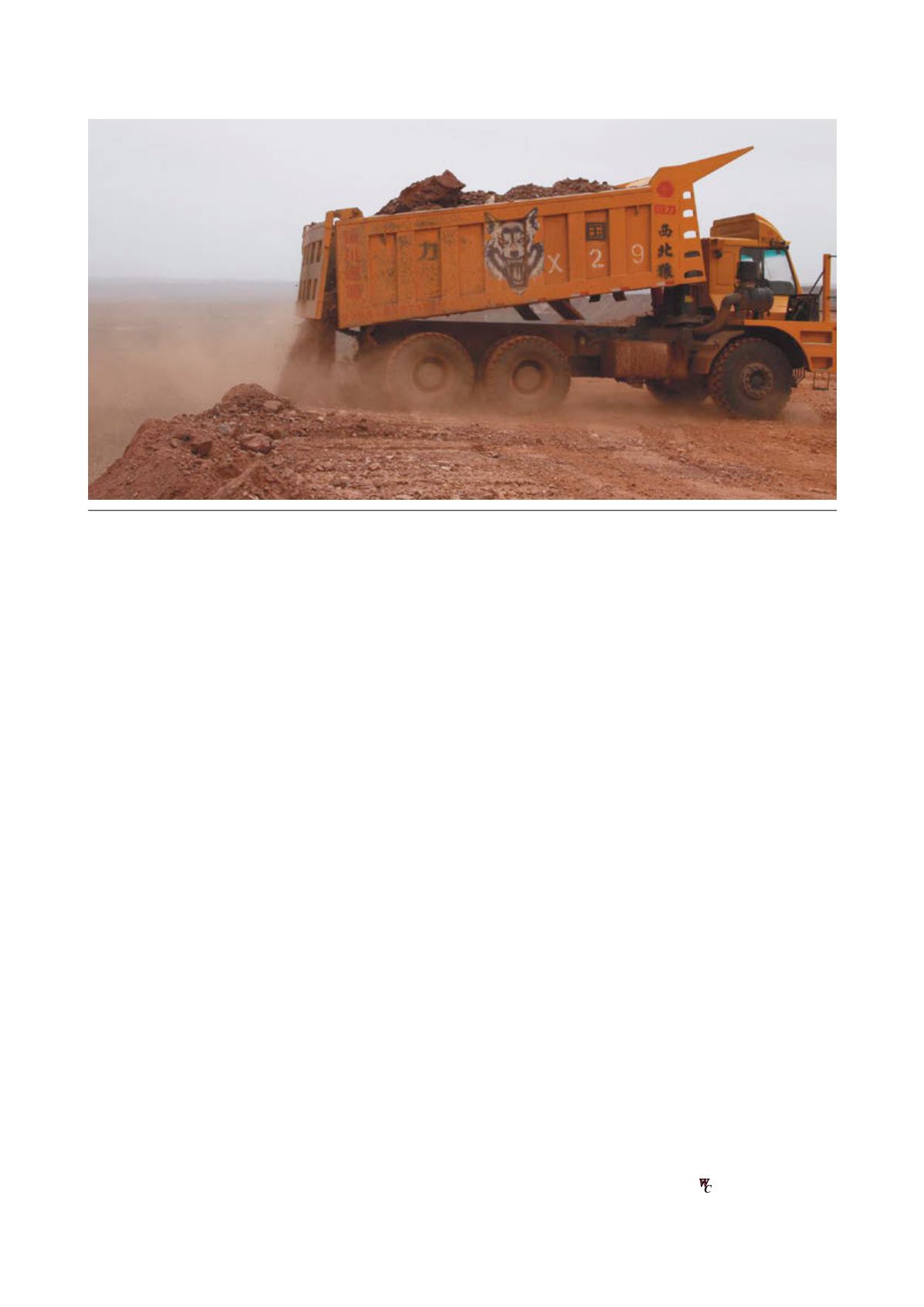

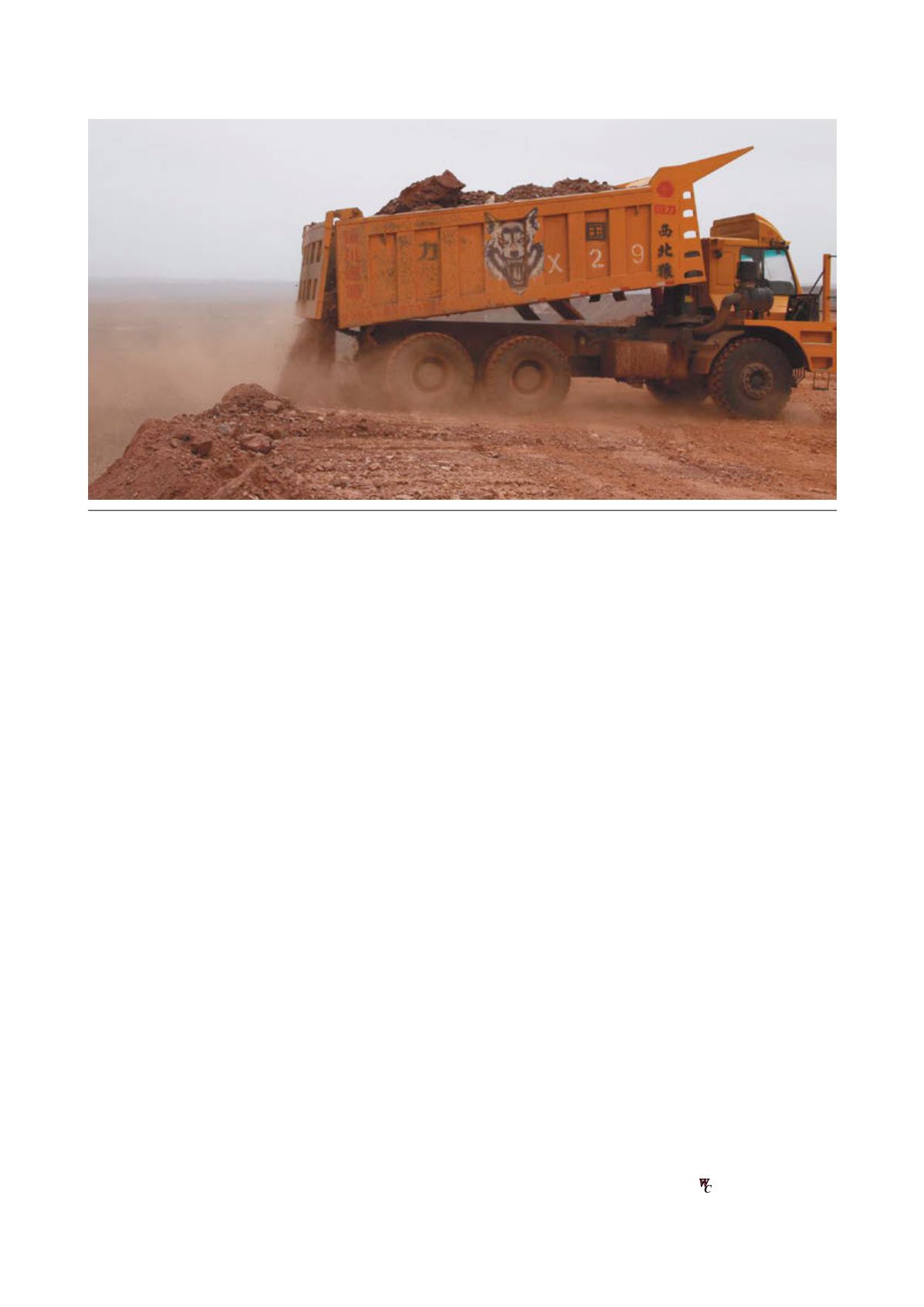

By using a carefully configured

torque converter, the automatic

transmission system can deliver

maximum torque both in first gear

and at a very low RPM. This is vital

when the Xi Bei Lang trucks need to

carry out their cliff-side

manoeuvres, as the delivery of

continuous torque through the

powertrain helps prevent any wheel

spin and jerking when the trucks

take-off after dumping their cargo.

This is a problem that was inherent

in the manual transmissions found

in the previous fleet of dumper

drucks. These trucks would slide

backwards when attempting to

climb the mine’s steep inclines of

over 200 m, making difficult

drop-off manoeuvres that much

more demanding.

As the Allison Transmission

system removes such problems, the

downtime required for tired drivers

and trucks with overworked

powertrains is reduced,

improving productivity.

The transition of

transmission

While the aforementioned

manoeuvre highlights the benefits of

an Allison Transmission system

when it comes to truck drivability

and operation, the need for little, no

regular or unscheduled maintenance

is key in propelling productivity

performance of powertrains.

Before purchasing the Xi Bei Lang

mining dump trucks, Xinjing Coal

imported trucks equipped with

manual transmissions to carry out

transport duties on the site. As the

mine’s unforgiving terrain requires

truck drivers to make constant gear

changes, it led to countless

breakdowns that required repair

parts. These could take a month or

longer to ship from OEMs overseas.

At one time, there were as many as

50 manual vehicles awaiting repair;

these trucks sat idle at a cost of

3000 – 4000 yuan/day per driver.

Such downtime needed to be

avoided if the Xinjing mine was to

operate efficiently.

Since automatic transmission

systems select the ideal gear for the

road conditions, powertrain wear

(and associated maintenance) is

avoided. Where time and

productivity has such a significant

effect on a mining operation’s bottom

line profits, reducing the need for

maintenance – scheduled or

otherwise – is a margin enhancing

prospect that mining fleet operators

cannot ignore.

Conclusion

When considering the proven effect

it can have on a mining operation’s

productivity, it seems clear that the

careful combination of reliable,

high-performance off-highway

powertrain components is a vital

part of fleet specification. This is true

both before and during a mining

operation. In a crowded and

competitive industry, the powertrain

could be the difference between

failure and significant success for

both mining companies and

vehicle OEMs.

36

|

World Coal

|

September 2014

“Allison transmissions have high reliability and provide excellent maneuverability,” dump truck driver, Baoan, concluded. There is

nothing to worry about, as his truck dumps its 30 t load over a nearly 90˚cliff in the Gobi Desert.