February

2014

OilfieldTechnology

|

67

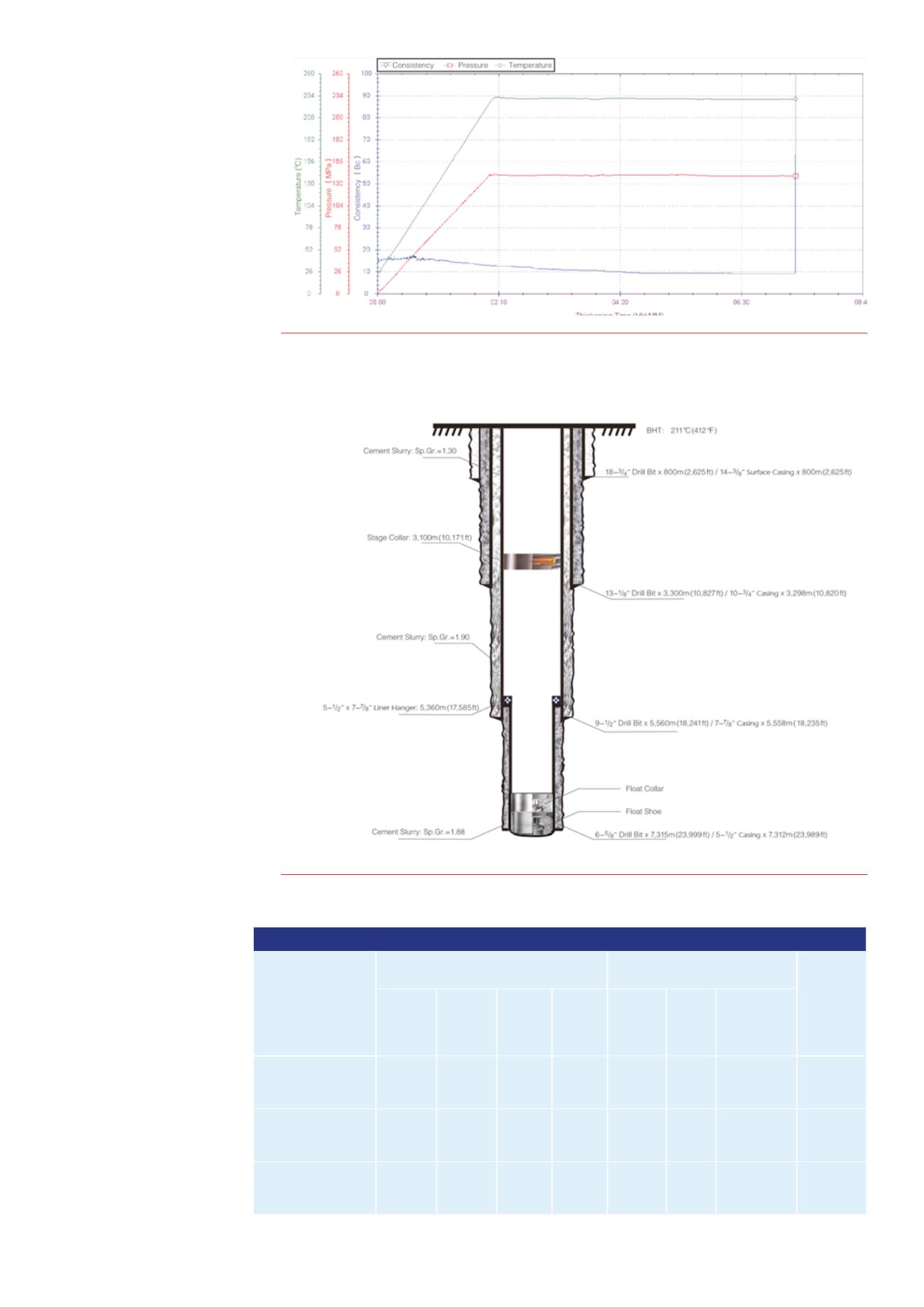

As the temperature

increaseswhenpumping the

cement slurry into the hole,

themolecular chains extend to

releasemore ions to strengthen

theprotectivefilms, so that

the thickening time increases.

Therefore, a smaller amount

of the additives is required

for greater results. After being

heateddown in thewellbore,

the cement slurrywill be

cooleddownwhen returning up

through the annulus, and the

molecular chains then contract

to recombine the extra retarding

ions in the cement slurry

togetherwith the selective

preference of thepolymer

monomers. So, the slurry

develops strengthquickly.

Goodlinearrelationship

Figures 1, 2 and 3 show the

linear relationshipbetween

the thickening time andweight

percentage of GT‑20L retarders

in the total solidphase. The

formula’s components (except

water) used for testing are

referred to inTable 1. The

thickening time versusweight

percentage of GT‑20L retarders

added is in a good linear

relationship, the thickening

time increaseswith the

increasing of GT‑20L retarders’

weight percentage, so it is easy

to control the thickening time

by adjusting thedosage of the

retarders.

Superhightemperature

cementingjobs

Figure 4 shows the evaluation

testing results at 446˚F.

The formula’s components

(exceptwater) used for

testing are referred to in

Table 2. From Figure 4, the

following conclusionwas

obtained: the additives

canbe used for super high

temperature cementing jobs.

Figure 4 shows the

evaluation testing curve

for the cementing job

planning of cementing the

annulus between 5

½

in.

liner and 6

⅝

in. hole in the

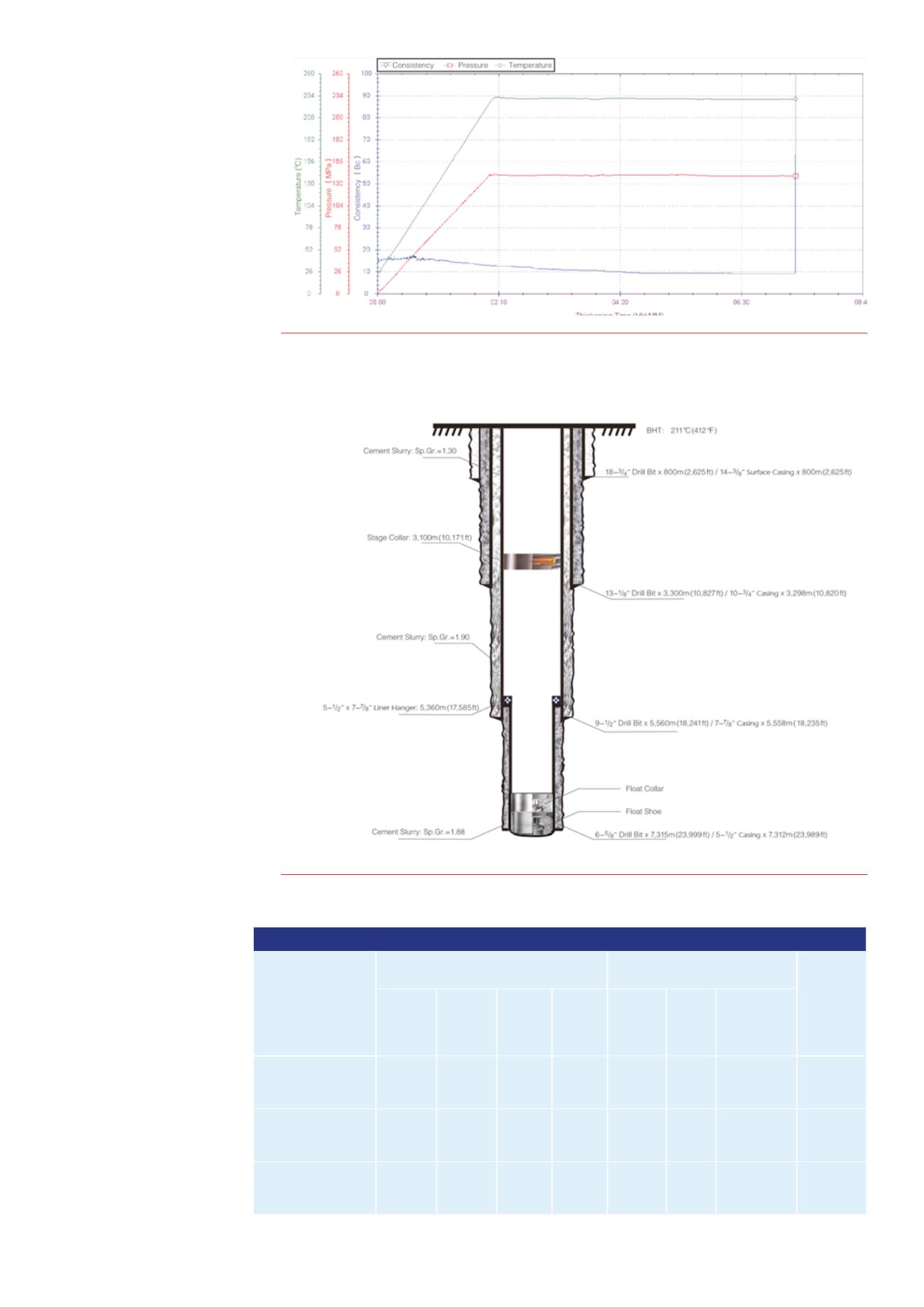

Gucheng Xwell. Figure 5

shows the casingprogramme

Figure4.

Thickeningcurveat230˚C(446˚F).

Figure5.

CasingprogrammefortheGuchengXwell.

Table 1. Formula of solid cement (320˚F)

Component

Liquid additive’s percentage (weight of

additive/total solid phase’sweight)

Weight of cement and other

solid additives (lb)

Total

solid

phase’s

weight

(lb)

GT‑10L GT‑20L GT‑30L GT‑66L

ClassG

cement

Silica

fume

Micro‑silicon

Figure 1, 321 ˚F

(160.8 ˚C)/17 303 psi

(119.3Mpa)

5.00

3.70

1.50

0.10

100

35

5

140

Figure 2, 322 ˚F

(160.9 ˚C)/17 390 psi

(119.9Mpa)

5.00

4.20

1.50

0.10

100

35

5

140

Figure 3, 321 ˚F

(160.6 ˚C)/17 361 psi

(119.7Mpa)

5.00

4.80

1.50

0.10

100

35

5

140