66 |

OilfieldTechnology

February

2014

additives and auxiliary agentsmust nowhave the following

features:

Ì

Ì

A high temperature resistance to at least 412˚F.

Ì

Ì

Suitability for awide range of temperature differences of

230˚F ormore because one stage lone zone cementingwill

be required for somewells.

Ì

Ì

High salt resistance.

Ì

Ì

Suitability for cementing jobswith very high Sp.Gr. slurry

(Sp.Gr. = 2.8) or very low Sp.Gr. slurry (Sp.Gr. = 1.1).

Ì

Ì

Suitability for high pressure gaswells (maximum bottom

hole static pressure is 17 600 psi), then great bonding

capability and anti‑gas channelling is required.

Ì

Ì

Simple formulation and no pumping issues.

Anewseriesofadditives

Over thepast few years of research, evaluation and through

servicinghundreds of wells inCNPC’s TarimBasin inChina,

Landy Energy Services, Inc. has developed a series of cementing

additives called Intelligent Temperature AdaptableCementing

Additives (ITACA).

These canbe used for

cementing conventional wells,

and they can alsobe added into

cement slurry for super deep

andHPHTwells.

The series includes:

Ì

Ì

GT‑10 fluid loss additive

(GT‑10L is in liquid form,

GT‑10S is in solid form).

Ì

Ì

GT‑20L retarders (in liquid

form).

Ì

Ì

GT‑30 drag reducing agent

(GT‑30L is in liquid form,

GT‑30S is in solid form).

Ì

Ì

GT‑66L defoamer (in liquid

form, whichwasmodified

fromGT‑60L defoamer).

Ì

Ì

GT‑70S stabiliser (in solid

form).

Ì

Ì

GT‑600Sweighting agent (in

solid form, Sp.Gr. =

6.8 ~ 7.4).

Ì

Ì

The above additives are all

resistant to 464˚F.

Also, the following

auxiliary additives havebeen

developed:

Ì

Ì

GT‑50S anti‑gas channeling

agent (in solid form,

resistant to 392˚F).

Ì

Ì

GT‑116Lwashing‑out and

isolating agent (in liquid

form, suitable for both

water and diesel‑basedmud

displacement).

Ì

Ì

GT‑160S alleviating agent

(in solid form, Sp.Gr. = 0.58

~ 0.62, pressure rating =

10 000 psi).

Ì

Ì

GT‑HW‑2 non‑conductive

weighting agent (in solid,

Sp.Gr. = 5.2 ~ 5.8).

Intelligentadditives

For the ITACA series, hydration

is achievedmainly through

macro‑molecules beingdirectly

adsorped in theGT‑10L(S)

fluid loss agent and theGT‑20L

retarders, and is also controlled

by the concentrationof the

retardingmolecules in the

cement slurry.

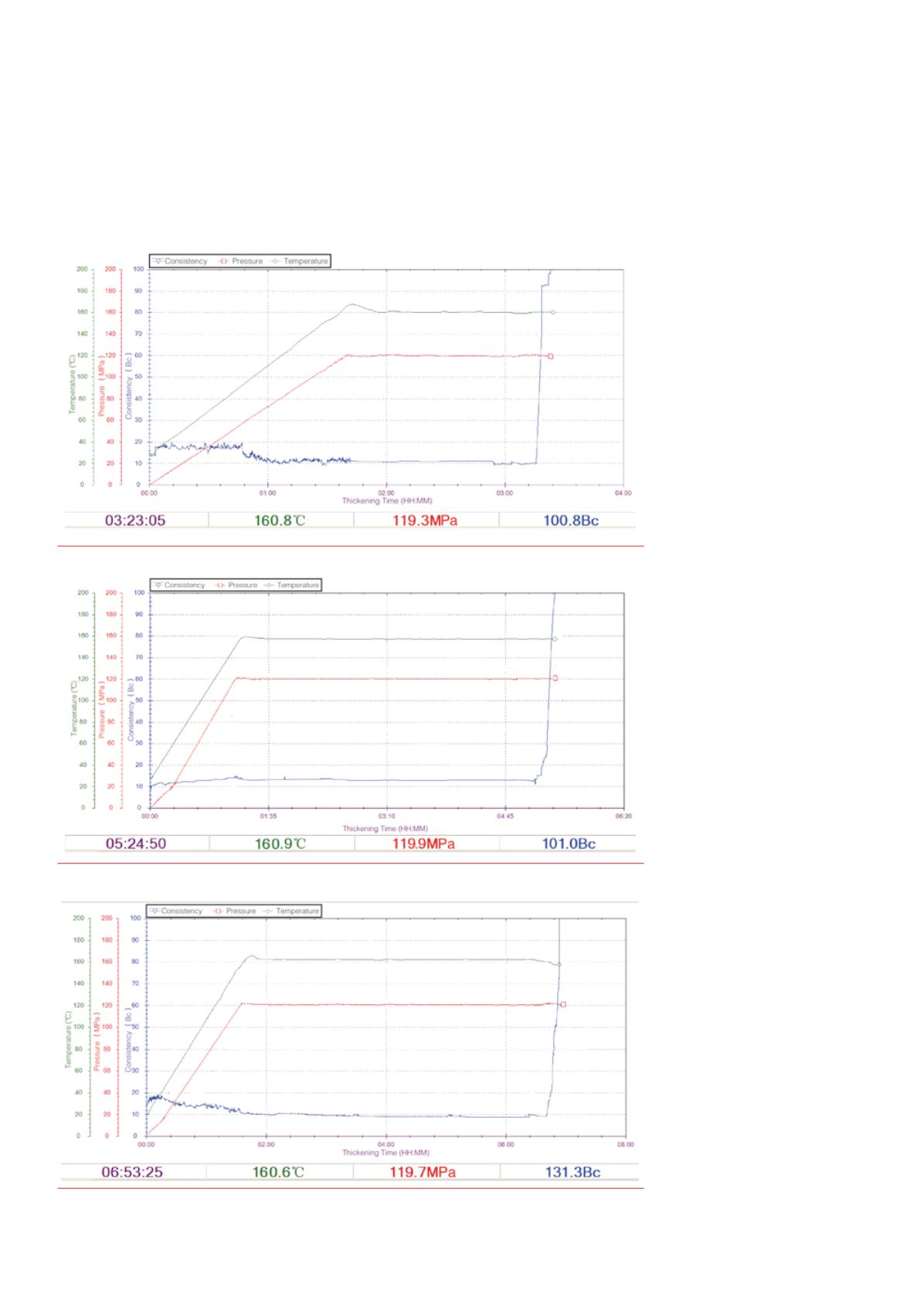

Figure1.

ThickeningcurveAat160˚C(320˚F).

Figure2.

ThickeningcurveBat160˚C(320˚F).

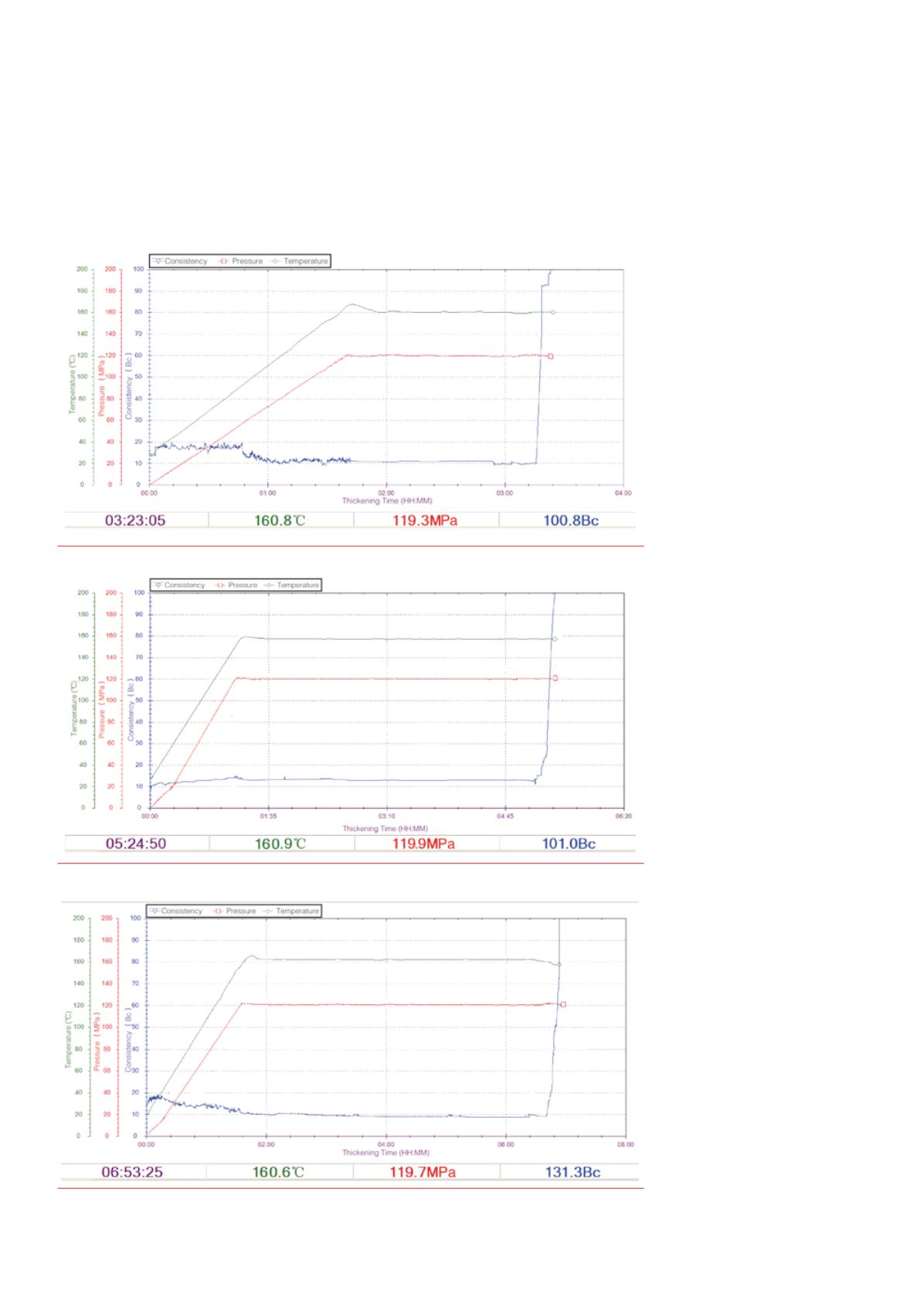

Figure3.

ThickeningcurveCat160˚C(320˚F).