70 |

OilfieldTechnology

February

2014

presenceof greater than1%of carbonaceousmaterials. The

amount of clays – largely kaolinite,montmorillonite,mixed layer

and illite – can vary frombeingaminor toamajor constituent of a

shale.Mullenhas shownhow themineralogical compositionof the

shale varies fromwell‑to‑well in theEagleFord shaleplay, andhis

findings are reproduced inTable1.

1

As illustrated inTable 1, shale composition can vary in

both total clay content andmineralogy. Therefore, the fluid

compositionproviding optimumperformance for drilling,

completion and stimulationoperationsmay vary across a single

field. Knowledge of these changeswithin the shaleplay is

required tomaximise the efficiency of a givenoperation type.

The shale/fluid incompatibilities causedby an improperly

formulated aqueous fluid arise from the interactionof water

with the clayminerals present in the shale. Clayminerals

are hydrous aluminiumphyllosilicates, sometimeswith

variable amounts of iron,magnesium, alkalimetals, alkaline

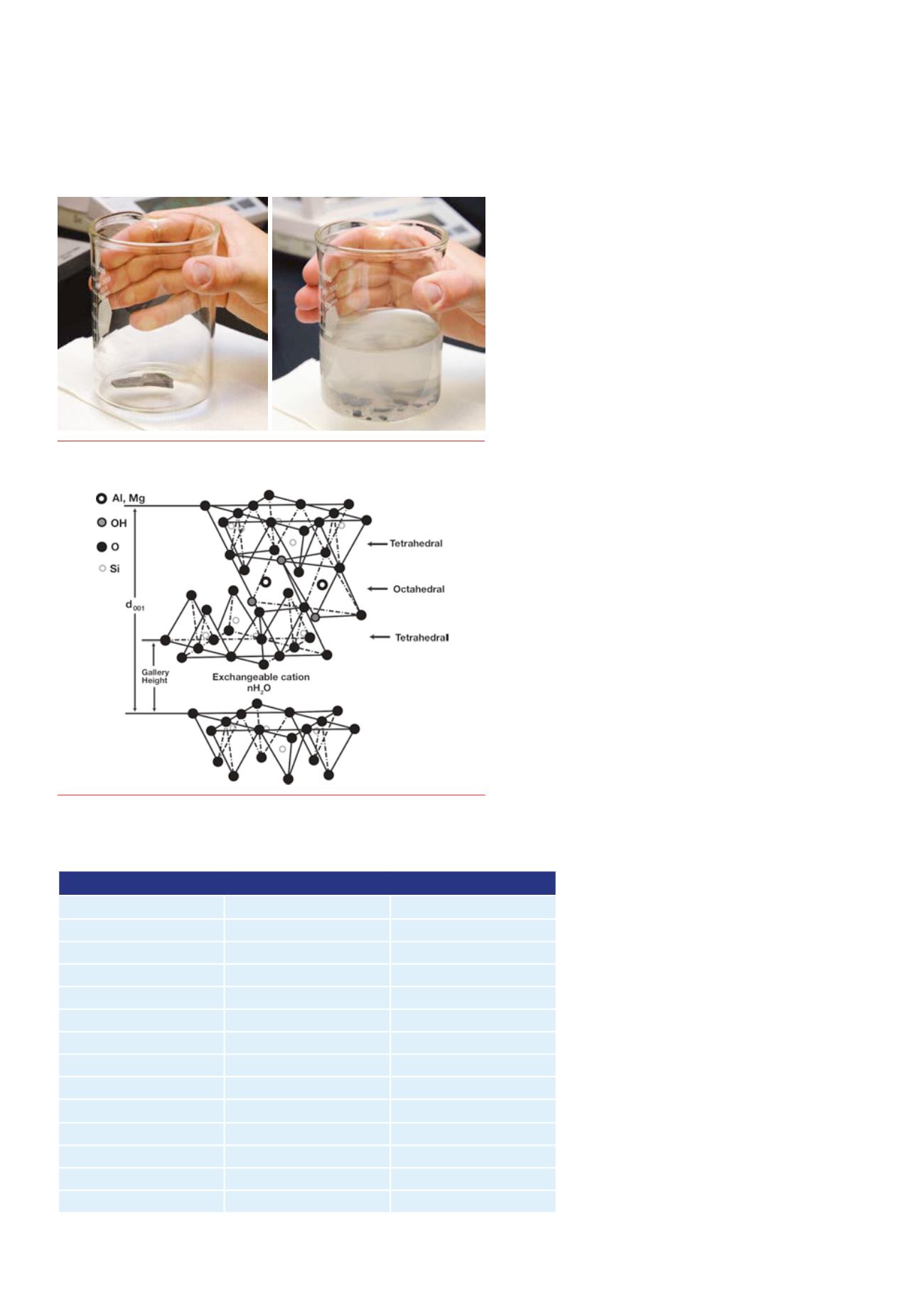

earths andother cations. Figure 2 shows the structure of

montmorillonite, also known as smectite, a common clay in

shale.

2

Montmorillonite clay forms flat hexagonal sheets or

plates, similar tomicas, which are less than twomicrons

in size. The surfaces of the clay platelets are negatively

chargedwhile the edges arepositively charged, and in an

undisturbed state thebalancing counter‑ions are usually

Na

+

. Clay particles hydrate in thepresence of water as

theNa

+

exchangeswithwatermolecules. As a result, the

montmorillonite expands considerablymore thanother

clays due towater penetrating the interlayer spaces and

concomitant adsorption. Depending on the chemical

characteristics of the shale, this can result in rapid swelling

or dispersionof the shale.

3

Indrilling, this can lead to

problems such as bit‑balling, disintegrationof cuttings,

boreholewashout, high torque anddrag and stuckpipe.

4,5

A variety of chemicals havebeenused to stabilise or

inhibitwater sensitive shales and clays over the years.

Black andHower described the use of potassium chloride

for fracturingwater‑sensitive formations in 1965.

6

This

was followedby other inorganic salts like sodium chloride

and calcium chloride,

7

aswell as tetraalkyl amine salts

8

such as ammonium chloride,

9,10

TMAC,

11

choline chloride.

12

Monomeric andpolymeric saccharides like glucosides,

13

fully

anionic PAC

14

andHEC

15

havebeenused, alongwith synthetic

polymers containing cationic,

8,16,17

anionic,

18

amphoteric

5

and

nonionic

19‑22

functionality.

As environmental toxicity has becomemore of a concern,

the use of anumber of these shale/clay inhibitors has been

discontinued inoffshore andother environmentally sensitive

areas. The toxic nature ofmany cationic

amines has limited their application in these

environmentally sensitive areas. Patel

3

compares

the toxicity of anumber ofmono‑, oligomeric‑

andpoly‑cationic amine‑based shale inhibitors

withpolyethylene imine salts

23

andoligomeric

ether amine salts

24

that show excellent shale

inhibition and are notmarine toxic.

With thewide variety of shale stabilisers

available for use, the choice of aparticular

shale inhibitormust be justifiedbasedon

several factors, such as performance, toxicity,

availability, cost and compatibility for a specific

shale formation. Shale inhibitor performance

and toxicity are the twomost important issues.

Anumber of laboratory tests exist for screening

shale reactivity todrilling and stimulation fluids.

Thesemethods include thin section analysis,

scanning electronmicroscopy (SEM), cation

exchange capacity (CEC), X‑ray diffraction

Table1. EagleFordShalemineralogical comparisonbetweenWell 1andWell 3

Mineral composition

Well 1

Well 3

Marcasite

1%

1%

Pyrite

5%

3%

Dolomite+FeDolomite

0%

2%

Calcite

55%

59%

Plagioclase

2%

3%

Quartz

15%

21%

Fluorapatite

1%

0%

Clays

20%

11%

Claycomposition

Well 1

Well 3

Kaolinite

7%

32%

Illite/smectite

53%

43%

Illite/mica

36%

25%

Chlorite

5%

0%

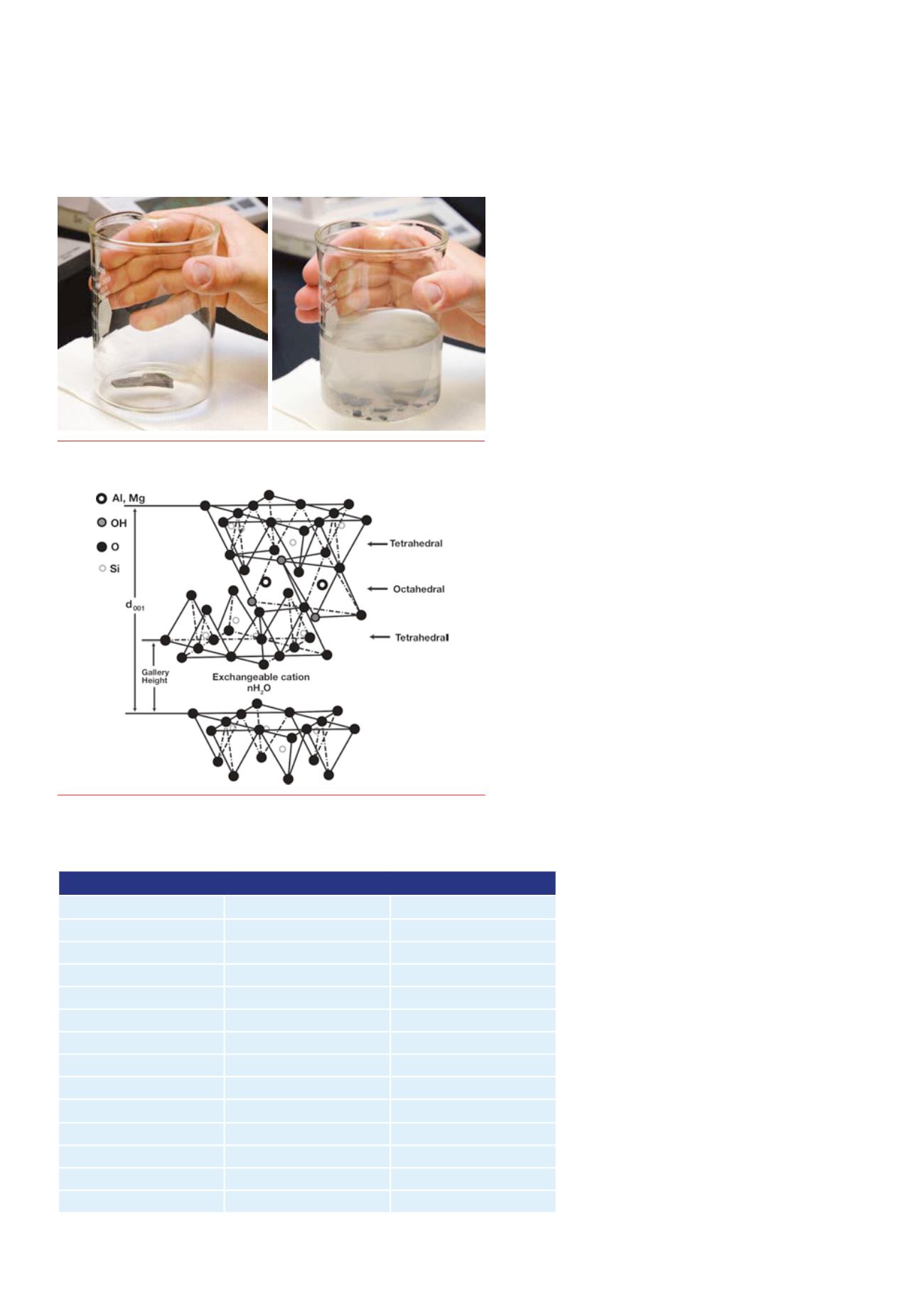

Figure1.

DisaggregationofMidwayshalewhenplaced intofreshwater.

Figure2.

Thestructureof2:1smectiteclays;d001referstothebasal

interlayeringspacing.ExtractedfromChenetal.(2008).Reproducedby

permissionoftheRoyalSocietyofChemistry.