February

2014

OilfieldTechnology

|

71

(XRD), capillary suction time (CST), bentonite inhibition testing

dispersionmeasurements, linear swellmeter (LSM) testing,

immersion testing, bulk hardnessmeasurements, water activity

measurement, fracturedevelopment tests, regainedpermeability

testing and fracture flow capacity testing.

23,25

In general, capillary

suction time (CST), bentonite inhibition tests anddispersion

tests are used to initially evaluate anew shale inhibitor. These

testswere used to compare three common shale inhibitors, KCl,

polyetheramines (oligomeric ether amine salts) and choline

chloride

3

to anovel product thatwas developedon thebasis of

low toxicity and enhanced shale inhibitionperformance.

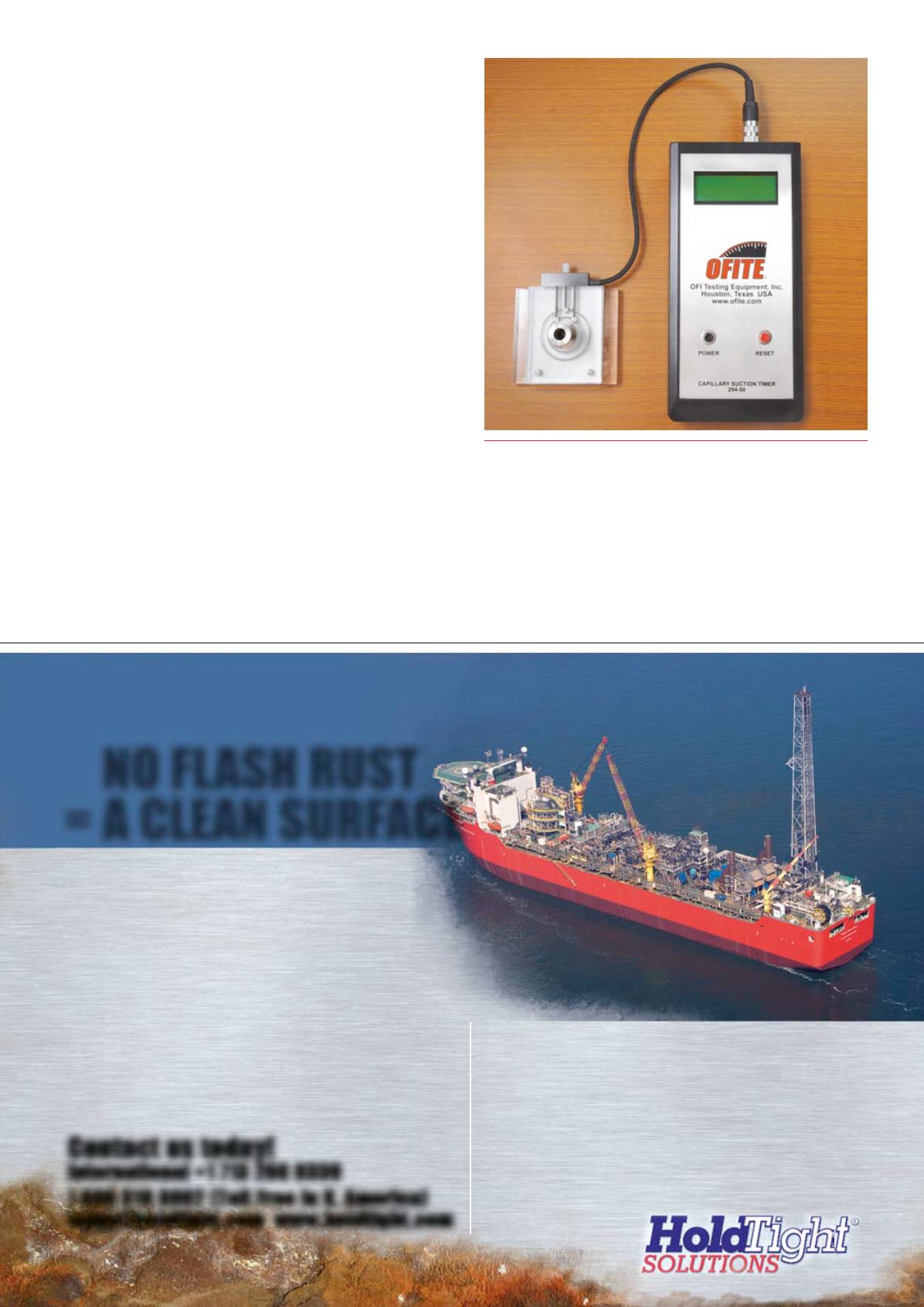

For CSTmeasurements, anOFI 294‑50 capillary suction timer

was equippedwithWhatman 17CHR filter paper (Figure 3). An

aliquot of 1 ‑ 2ml freshly prepared inhibitor‑claymixturewas

injected via transfer pipet into the timer reservoir and theCSTs

were recorded. Lower CST values indicate a lower interactionof

thewaterwith the shale andbetter shale inhibition (Figure 4).

Bentonite inhibitor rheological testswereperformedwith an

AntonPaar 302 rheometer using concentric cylinder geometry. A

20ml sample of an inhibitor‑bentonitemixturewas poured into

the sample cup, and the samplewas sheared from 100‑1 sec

‑1

at

25˚Cwhile viscositywas recorded as a functionof shear rate.

Lower viscosities indicate a stronger interactionof the shale

inhibitorwith thebentonite, leading to lower levels of bentonite

deflocculation (Figure 5).

Shaledispersion testswere runonMidway shale samples

that hadbeen retainedby a 16‑mesh sieve. The large shale

pieceswere treatedwith 3% shale inhibitor solutions and sealed

inpressure cells pressurisedwithnitrogen. The cellswereplaced

into apre‑heated roller oven and initially rolled for 16 hours at

250˚F.

3

The cellswere cooled in awater bath and the contents of

the cellswere collectedonto the 16‑mesh sieve anddried. The

mass of the inhibitor‑exposed shale after hot‑rollingdividedby

the initialmass of samplemultipliedby 100 gave thepercentage

of shale retained. The higher thepercent shale retained from the

NOFLASHRUST

=

ACLEANSURFACE

HoldTight

®

102 is the standardof

performance for preventingflash rust:

Among rust preventers and salt removers,

HoldTight

®

102 is themostwidelyused, reliable,

time-proven, lab-tested, field-tested, recommended

and approvedbymost coating companies.

Call, email or visit ourwebsite today to seewhy

HoldTight

®

102 is thebest option for low-cost,

easy-to-achieve, and easy-to-measure

contaminant-free surfacepreparation.

•

NOSALT.

Removes all contaminants

•NORUST.

Leaves a rust-free surface for 48hours or

more – often 3 to 5days

•NODETECTABLERESIDUE.

There is nothing left on the surface that

might interferewith your coating.

YOUKNOW ITWHENYOUSEE IT

Contact us today!

International +1 7132669339

18003198802 (Toll Free inN. America)

FSOBTERRANOVAPHOTOCOURTESYOF SUNCORENERGY

Figure3.

OFI294‑50capillarysuctiontimer(CST).