64 |

OilfieldTechnology

February

2014

TheLloydminsterareapresentstwomainchallenges–SCVFsand lost

circulationwhilecementing.Thesechallengesarenormallydealtwith

byusingthixotropiccements, lowfluid loss,zerofreewaterandacritical

intervalof lessthan30min.Sinceasignificantamountofworkhasbeen

completed intheareawithsuccess,theSCVF issuetypicallydoesnotarise.

Inoneparticularproject,described indetail inSPE157922 ‘Elimination

ofSurfaceCasingVentFlowandGasMigration intheLloydminsterArea’,

thefirstcoupleofwellswerecementedusingastandardtemperature

profile.Subsequentwellshadahigherthanexpectede ectiveECD.The

cementblendwasmodifiedtoaccountforthe increasedtemperature

withoutconsiderationforthee ectofthemodificationstotheproperties

describedabove.Thismodifiedblendwasusedonthenextfourwells.The

operationalexecutionwasdeemedsuccessfulastheslurrywasplaced

withexcellentdensitycontrolwithgoodcementreturnstosurface.Eachof

thefourwellsexhibitedaSCVF. Inordertosatisfytheregulatoryboard,a

cementbondlog(CBL)wasrequired.Thebond logsrevealedareas inthe

wellthathadpoorbond.

An investigationwasconducted inorder to fullyunderstand

the issue. Itstartedwithunderstanding thesourceof thegas that

wasgetting tosurface.Asampleof thegaswas testedand revealed

that thesourceof thegaswas fromadepthofapproximately

265-325m (869-1066 ), identifyinganeed to furtherexplore that

specific formationdepth.

The increasedwell temperaturewas reported tohave

increased thecirculating temperature from20˚C (68˚F) to

approximately45˚C (113˚F).Upon further investigation, the

increase in temperaturewasdue to thebottomof thewellbore

beingwarm,butnota ecting theupholeareas.Thismeant that

whenstatic, thecementslurryupholewasnotsubjected to the

increase in temperatureaspreviouslyexpected.Thesignificanceof

this finding is that thegradientwithin thewellbore,despitebeing

relativelyshallow indepth, isveryhigh.AstudybySabins,Tinsley

andSuttonshowed thatawide temperaturegradientcouldhavea

negative impacton thesettingofcementat the topof thecolumn.

Thecementpropertycommonlyusedtoexplainsettingunder

staticconditions isthecritical interval.Thecritical interval is

determinedbyastaticgelstrengthtest,and isdefinedbythetime

between48Pa (100lbs/100

2

)and240Pa (500lbs/100

2

).When

thegelstrength is lessthan48Pa (100 lbs/100

2

), there isenough

hydrostaticpressure fromthecolumnofcementtoholdbackthe

downholepressure.Thetransition fromthispointtowhen ithas

enoughgelstrengthtoresistthepressure (240Paor500lbs/100

2

)

isconsideredthecritical interval.Sabins,TinsleyandSutton’sstudy

showedthatduringthistransition, fluidhasthebestchanceof

migratingthroughthecement.

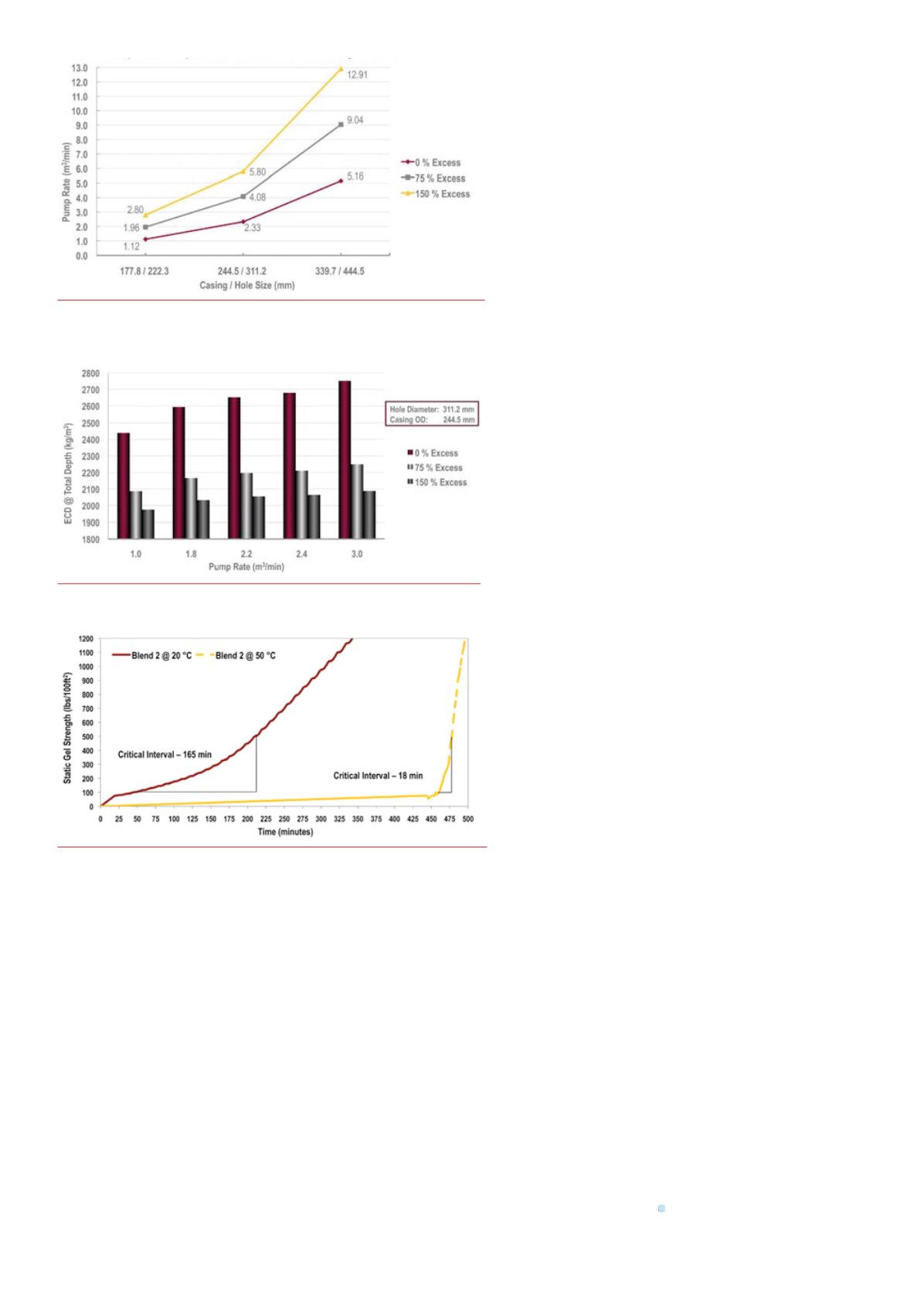

Thecritical intervalsof themodifiedblendwere foundtobe

165min.at20˚C (68˚F)and18minutesat50˚C (122˚F)asshown in

Figure3.

Thedesign temperaturewas50˚C (122˚F)and the

temperatureof theshallow formation,whichwas thesourceof the

gas,was20˚C (68˚F). Inorder toaid in thepreventionofSCVF,a

critical intervalof less than30min. is targeted.Themodifiedblend

was redesigned toachieveacritical interval less than30min.at

20˚C (68˚F).

Alongwiththis improvementtothemodifiedblend, thepump

rateswerealso increased inanattemptto improvedisplacement

e iciency. Inthis instance, the increase inpumpratescreatednew

challenges,as lostcirculationwasencountered.The lostcirculation

maybeaconsequenceofan increasedpumprate leadingtoan

increase intheECDthatthe formation isexperiencing.

Thepump rateswere reduced tomeeta targetECDand the

redesignedcementblendwasutilised resulting in improved

CBLsandeliminationof theSCVF.With the reducedpumping rates,all

thecementingoperationsattainedcement returns tosurface.

Summary

Bestpracticesareknownacross theoilandgas industrybyboth

servicecompaniesandE&Pcompanies,andsignificantworkand

investigationhasbeencarriedout indeveloping, improvingand

implementingdi erentbestpractices.Theareaand typeof

applicationwhereeachbestpracticeprovesmoste ectiveneeds to

bedeterminedso thatadditionalornewchallengesarenot

encounteredasa resultof implementation.Theexperienceand tools

available to theservicecompaniesandE&Pcompaniescan reduce the

learningcurve,buteachchallenge that isencounteredmustbe fully

understoodwithaproper investigation inorder to fullyeliminate the

issue.Onlyonce the issue iscompletelyunderstoodwillasolution,

whetherabestpracticeoracustomisedsolution,have thegreatest

chanceof solving thechallenge.

Figure3.

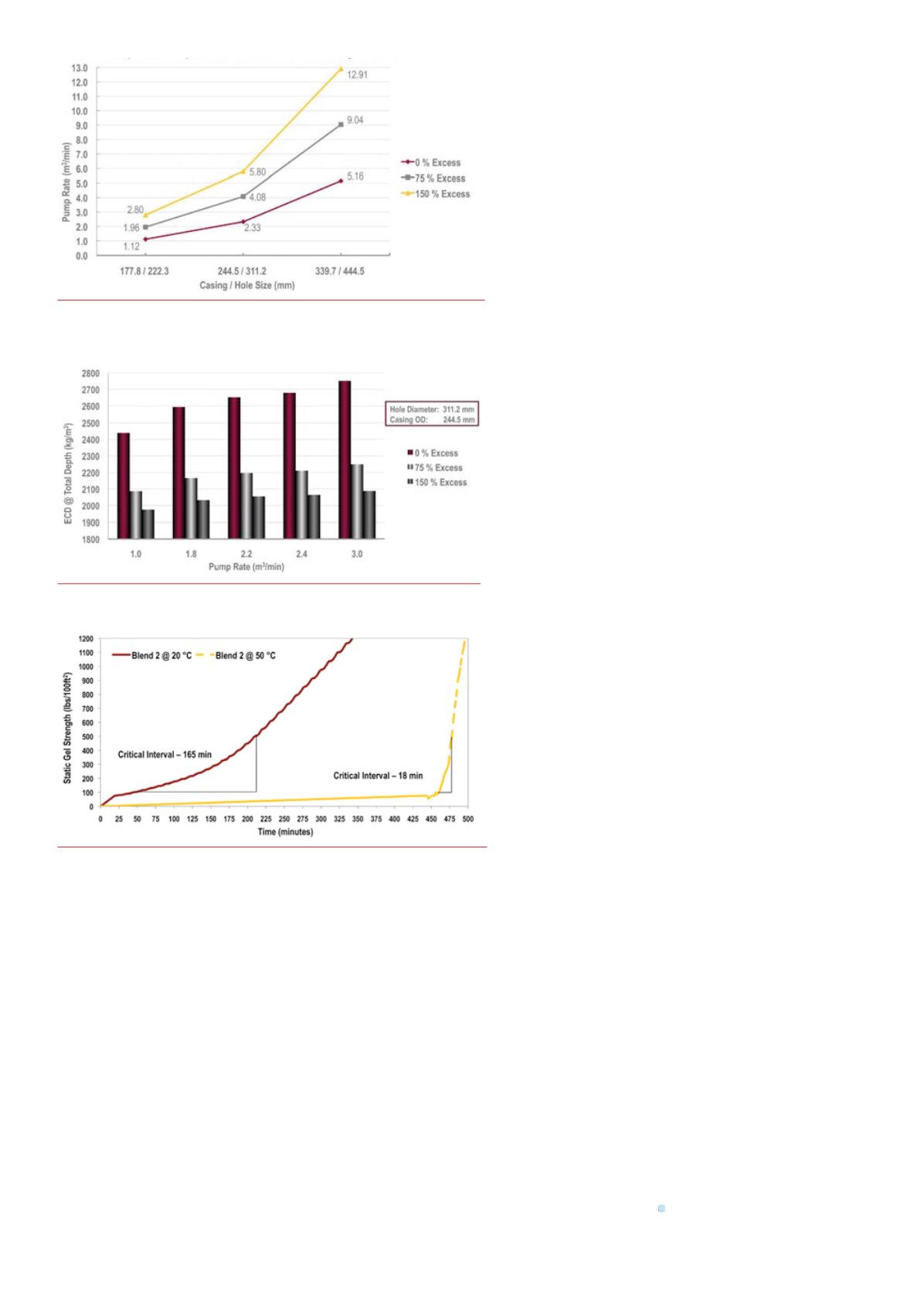

Pumpratesrequiredtoachieveannularvelocityof80m/min.

(262.5 /min.)forvariouswellboreconfiguration.

Figure4.

ECDversuspumprate.

Figure5.

Critical intervalat20˚C(68˚F)and50˚C(122˚F).