62 |

OilfieldTechnology

February

2014

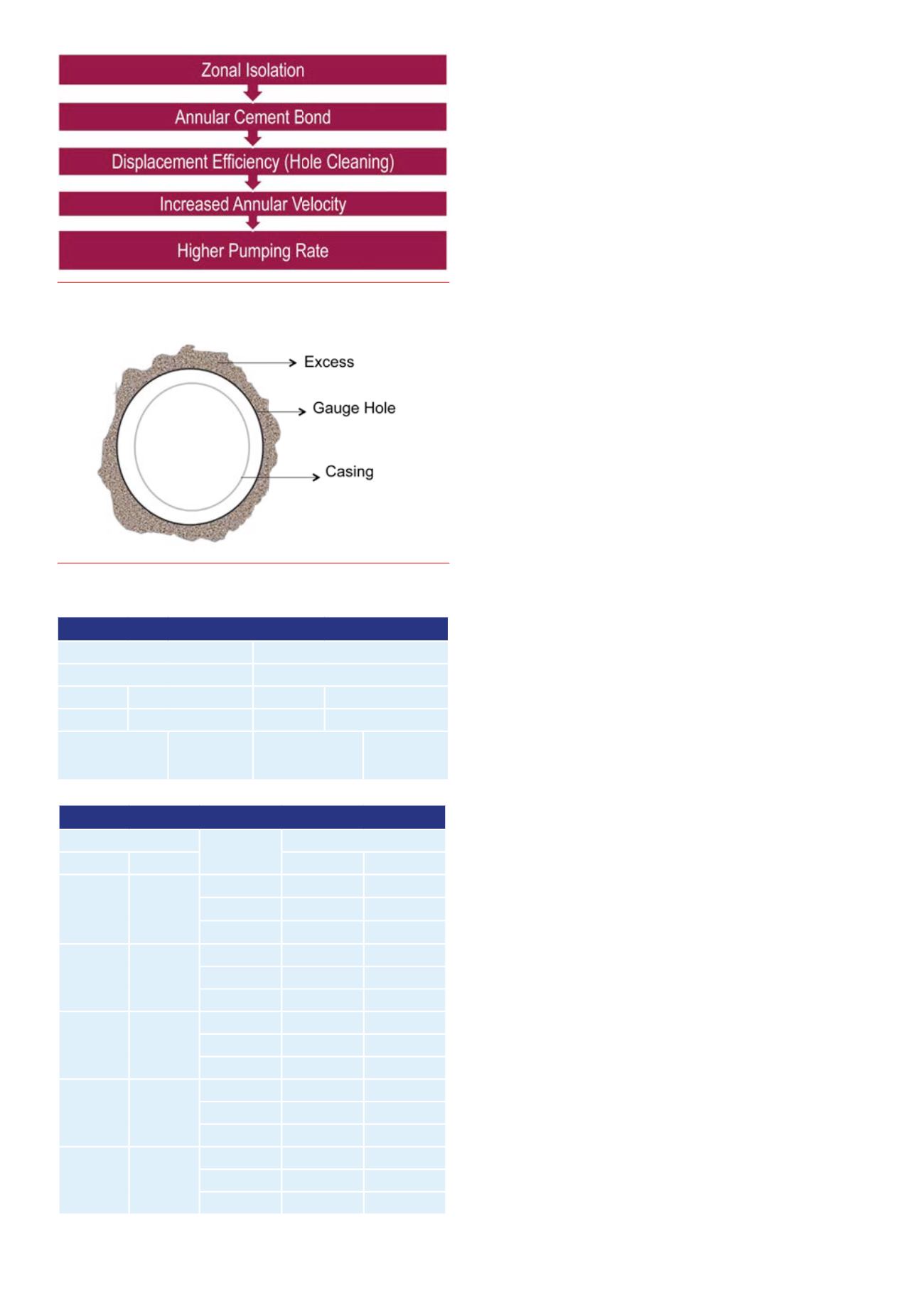

excessrequired isminimised,or isascloseto0%aspossible, isthrough

properdrillingtechniques;however,thismaynotbepossible inall

formations.Thereforetheabilityto increasethepumprate isrequired in

somecases.

Thisrequired increasedpumpratehasbeenmanagedafewdi erent

wayswithinthe industry:

Increasethepumpingabilityofasingleunit.

Usemultipleunitsduringanoperation.

Reviewmethodsto increasedisplacementefficiencythrough

differenttechnologies.

It is importanttoconsiderhowthesetechnologieswillcontinueto

develop inthefutureasthewellboreconfigurationcontinuestochange

inane orttomaximiseproduction.E&Pcompaniesare investigating

di erentconfigurationsthatsuittheirspecificrequirements. Ifthe

wellboresizescontinuetogrow,thesechallengeswillbecomemore

prevalent.Anexampleofthis isshown inFigure3,whereeven larger

casingsizesthanwhatmightcommonlybeusedtodayareexamined.

Figure3showsthat inawellboreconfigurationwhere339.7mm

(13

⅜

in.)casinganda444.5mm(17

½

in.)openholeareused,apump

rateof5.16m

3

/min. (32.5bbl/min.) isrequiredtoachieve80m/min.

(262.5 /min.)when0%excess isassumed.When150%excess is

taken intoaccountforthesamewellboreconfiguration,thepumprate

increasesto12.91m

3

/min. (81.2bbl/min.).

Whenapproachingratesofthismagnitude,therearemanynew

challengesthatarisefortheservicecompany.These include,butarenot

limitedto,thefollowing:

Surfacetreating ironpipevelocityrestrictions (increasederosion).

Horsepowerrequirementstoachievepumprates.

Spaceavailabilityon location forrequiredequipment.

Otherchallenges

OtherchallengesariseforboththeservicecompanyandE&Pcompany.

Oneofthesechallenges isthe increasetotheECDthatthewellbore

experiencesduringtheoperation.Astherate increasesforagiven

wellboreconfiguration,theECDalso increases.Anexampleofhowthese

valuescanchange isshown inFigure4.

InFigure4,theholeandcasingsizesare311.2mm(12

¼

in.),and

244.5mm(9

⅝

in.)respectively.Thegraphshowsthatforeachofthe

threeexcessvaluesassumed,theECD increaseswithan increase inpump

rate. Italso illustratesthatthemostdramatic increaseoccurswhere0%

excess isassumed.Theothertwoexamplesshowamuchmoresubtle

increase inECD.

An increase intheECDcan increasethe likelihoodofbreaking

downtheformation,or inducing losses, iftherockcannotwithstand

theforcesexertedon it. Inmanyoperations,anallowableECD isknown

andtheservicecompanyplanstheoperation inordertomaintainan

agreed-uponvalue. InanattempttomaintaintheallowableECD,the

servicecompanymaybeforcedtoreducetherecommendedpumprates

and/ormodifythecementslurrytomake iteasiertopump.These

modifications includedi erentmethodstoreducetheviscosityofthe

cementslurry.

Increasingannularvelocityhasprovene ectivefor improving

cementbond logs inmanyoftheSAGDareaswhere ithasbeenutilised.

However,therearealsoexampleswhereahighpumpratehasnotbeen

ase ectiveasexpected,both inSAGDwellsandotherareas.Forexample,

higherrateswere introducedasapossiblesolution indealingwithsurface

casingventflows(SCVFs) intheLloydminsterareaofWesternCanada.

SCVFsaredefinedasgascomingtosurfacefromthegroundandbetween

thesurfacecasingandtheproductionstring.TheoccurrenceofanSCVF

indicatesthedesiredzonal isolationwasnotsuccessfullyachieved.

Sincehighratepumping is intendedto improvezonal isolation, itwas

consideredasapossiblesolution inthisareawhereSCVFsarecommon.

Table1. Comparisonof conventional andSAGDwell requiredpump rates

Conventionalwell

SAGDwell

Intermediatehole:

Intermediatehole:

Openhole 222.3mm (8

¾

in.)

Openhole 311.2mm (12

¼

in.)

Casing

117.8mm (7 in.)

Casing

244.5mm (9

⅝

in.)

Pump rate to

achieve80m/min.

(262.5 ft/min.)

1.1m

3

/min.

(6.9bbl/min.)

Pump rate to

achieve80m/min.

(262.5 ft/min.)

2.3m

3

/min.

(14.5bbl./

min.)

Table2. Pump ratesandexcess

Pump rate

Excess (%)

Annularvelocity

m

3

/min.

bbl/min.

m/min.

ft/min.

1

63

0

34.35

112.7

75

19.63

64.4

150

13.74

45.1

1.8

11.3

0

61.83

202.9

75

35.33

115.9

150

24.73

81.1

2

12.6

0

68.7

225.4

75

39.26

128.8

150

27.48

90.2

2.2

13.8

0

75.57

247.9

75

43.18

141.7

150

30.23

99.2

2.4

15.1

0

82.44

270.5

75

47.11

154.6

150

32.98

108.2

Figure2.

Gaugeholeandexcess.

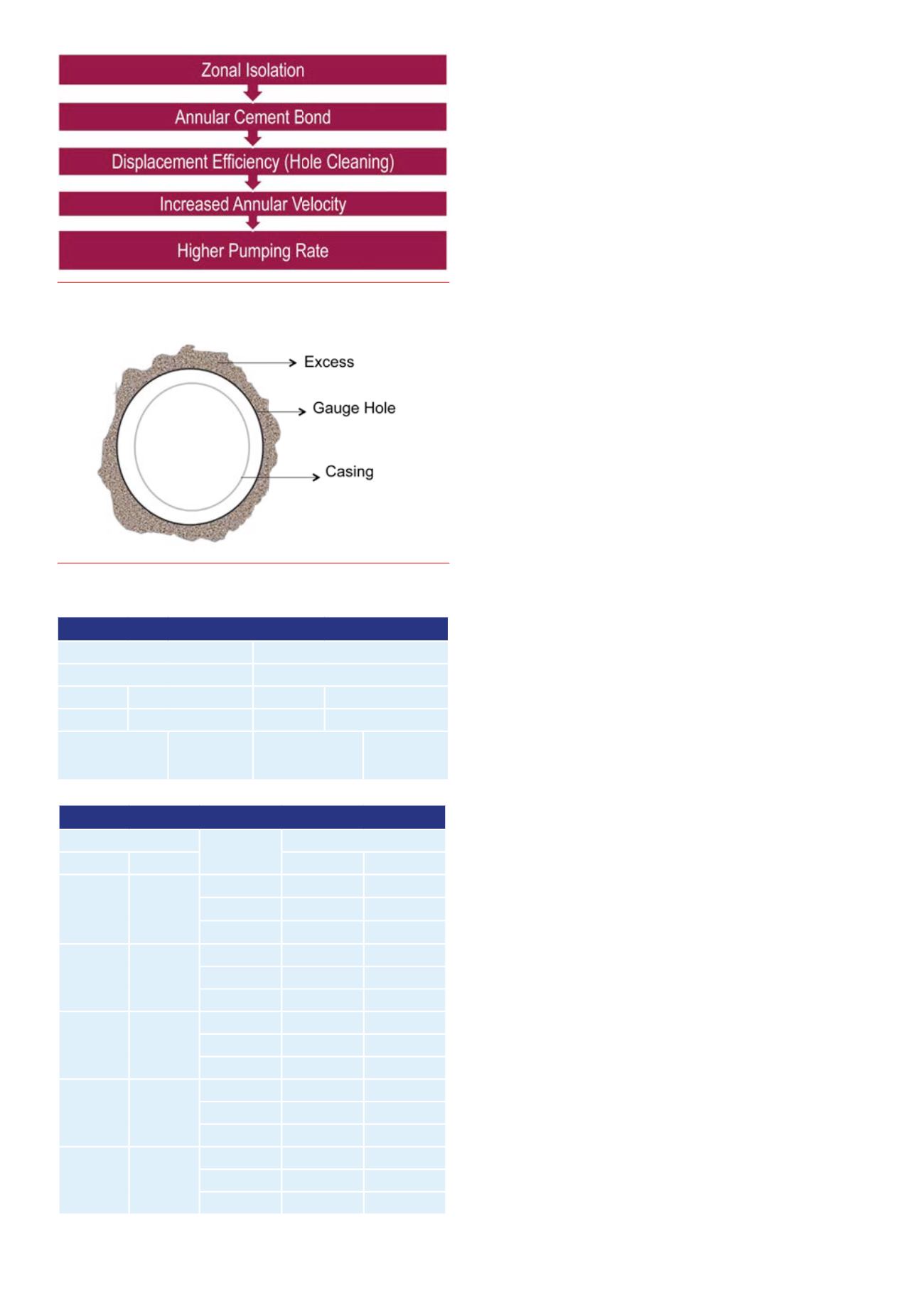

Figure1.

Pumprateandzonal isolation.

C

M

Y

CM

MY

CY

CMY

K