36 |

OilfieldTechnology

February

2014

Inaddition, noaccess roadorpadwasprepared inadvance, due to

the lowmarginsassociatedwith thewells.

Phase1:wellsoverbalancedwithmud

The firstphaseof thecampaignconsistedofdrilling threewells

overbalancedwithmud.OnewellwasanS-curve, and twowells

weredeviated tovaryingextents. Armedwith thePOLARIS tool, the

AnTech teamworked inconjunctionwithaspecialistCTD rigpartner

usingahybrid land rig.Byusingahybriddrilling rig, drilling timecan

be reducedbyup to60%compared todrillingwithaconventional

jointedpipe rig.

The firstwellwasanS-curvewelldrilled tonearly3000ftTVDand

over600ft lateraldisplacement (Figure2).

Theplanned targetwassituatedunderproductive farmland.

AnTechwasable todrill thewellbyplacing the rigonadjacent land

andsetting the trajectoryso that therewouldbenodisruption to the

landowner (Figure3).

The reservoir targets ofWells 2and3were situateddirectly

below creeks, whichmeant that the rigagain couldnot be sited

above the reservoir target, therefore thedecisionwasmade to

drill deviatedwellbores. As a result, efforts toexploit the reservoir

werenot compromised. Followingaone-daymobilisation, the

teamdrilledWell 2 toover 1500 ft TVD, withanaveragedog leg

severityof approximately 7.5˚. Theaccurate steering capabilities

of thePOLARIS tool enabled the job tobe completed in less than

oneday.

For the thirdand finalwell ofPhase1, the team travelledsouth

to thedrillingsitenearGoodland,Kansas. ThePOLARIS tooldrilled

efficientlyalong thedrillingpath (over1100ftTVDand700ft lateral

displacement).Onceagain, theoperationwascompletedon time,

reconfirming theeffectivenessof thesolid-stateAcrobat™gyro

system, theunderlying technology thatmakes itpossible tomonitor

orientationof the tool.

Theuseof agyrosensor inPOLARISmeans that the tool isvery

short (BHA less than40ft). TheAcrobatgyrosensor is located just

behind themotor. Thisgivesquickdirectional feedback,which in turn

meansabetterwell trajectory.

Maximumaccess,minimalimpact.

Thecombineddirectional capabilityandcompactnatureof the

operationsmeant thatPhase1wasexecutedwithminimal impacton

theenvironment.Byusing thismethod, AnTechwasable toaccess

reservoir targets thatwouldnothavebeen feasibleusingvertical

drilling. Thewellsweredrilledundera riverbed, ahill and from the

edgeof acornfield,withoutdisrupting theongoingharvest. Theyalso

tookplace inareaswithnoaccess roadorprepareddrillpads. Low

marginoperationsof this typeareonlyviablewithasolutionof this

nature,whichcanbemobilisedquicklyandefficiently, anddrilled

rapidly.

Phase2:Horizontalwells4and5drilledwithair

The final twowellsweredrilledhorizontallywithair. Thebuild

sectionsof thesewellsweredrilledwithmudusingan8

½

in. bit. The

horizontal sectionsweredrilledwithanairmistusinga6

¼

in. bit. Air

wasused todrill thesewellsdue to thehighly fractured formations,

whichwereunable tosupport thepressureof a liquidcolumn.

Oneof thekeybenefitsof thePOLARIS tool is that itgenerates

reportsofdownholevibration in real time.DuringPhase2, shock

spikesofup to350gwere recordedby theaccelerometersduringair

drilling, or– tobemoreaccurate–with thebitoff-bottom. These

measurementsdemonstrate theneed forequipment that can

withstand theveryhighshockandvibrationenvironment thatoccurs

whendrilling inairorwithaerated fluids.

HorizontalWell 4wasdrilled to1090ftTVDandover1450ft

lateraldisplacement. The team thencarriedout thesecondoperation

onhorizontalWell 5,whichwasdrilled to1096ftTVDwitha lateral

displacementof 1103ft (Figure4).

As in the threepreviousdirectionaldrillingoperations, the

POLARIS tool steeredeasily, reconfirming theeffectivenessof the

Acrobatgyrosystemand itsability todrilldirectional andhorizontal

wells.

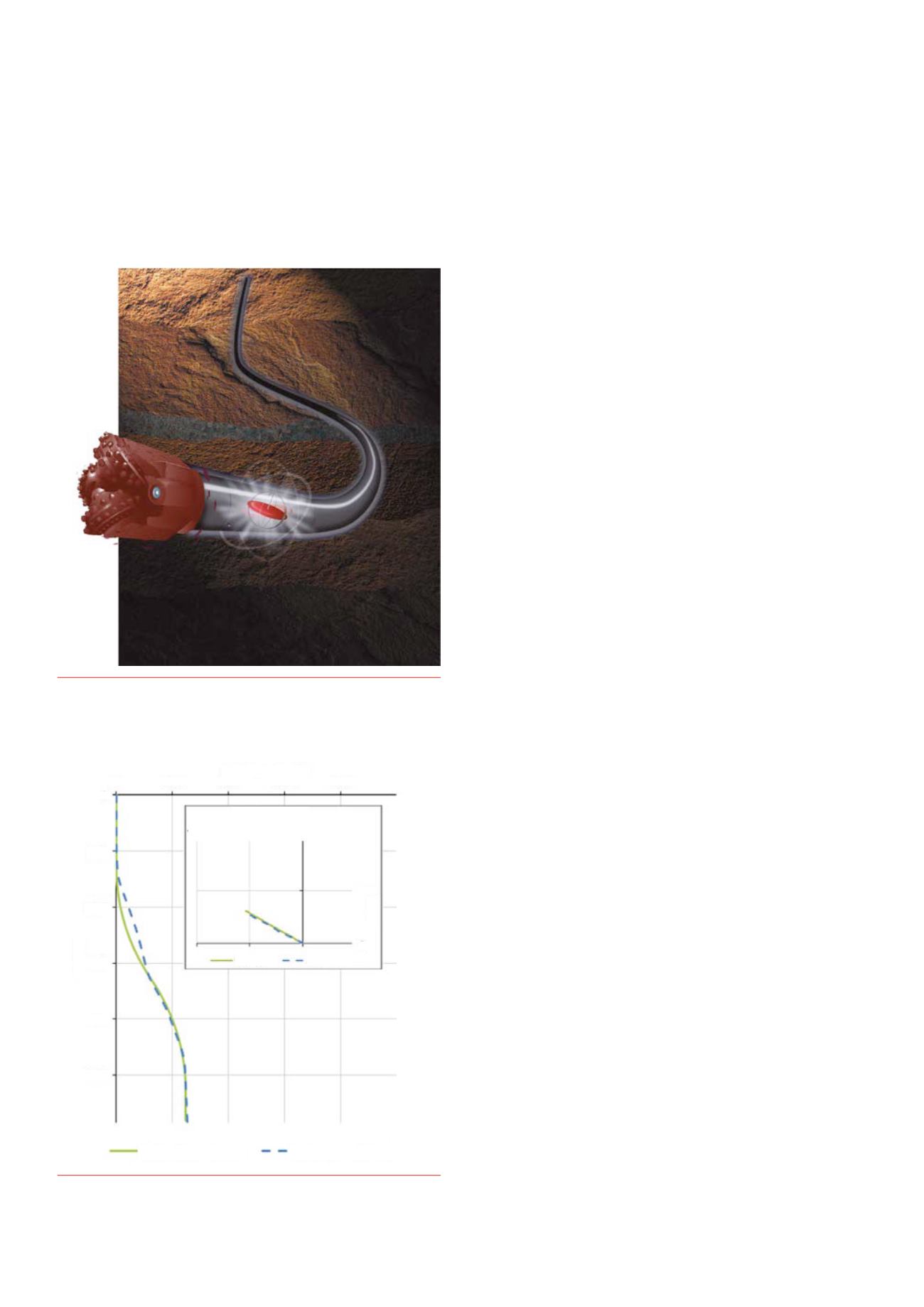

Figure1.

Usingsolid-stategyrotechnology,thePOLARISBHAforCTD

offersanaffordablewaytodrilldirectional,S-curveandhorizontalwells

inshallowreservoirs.

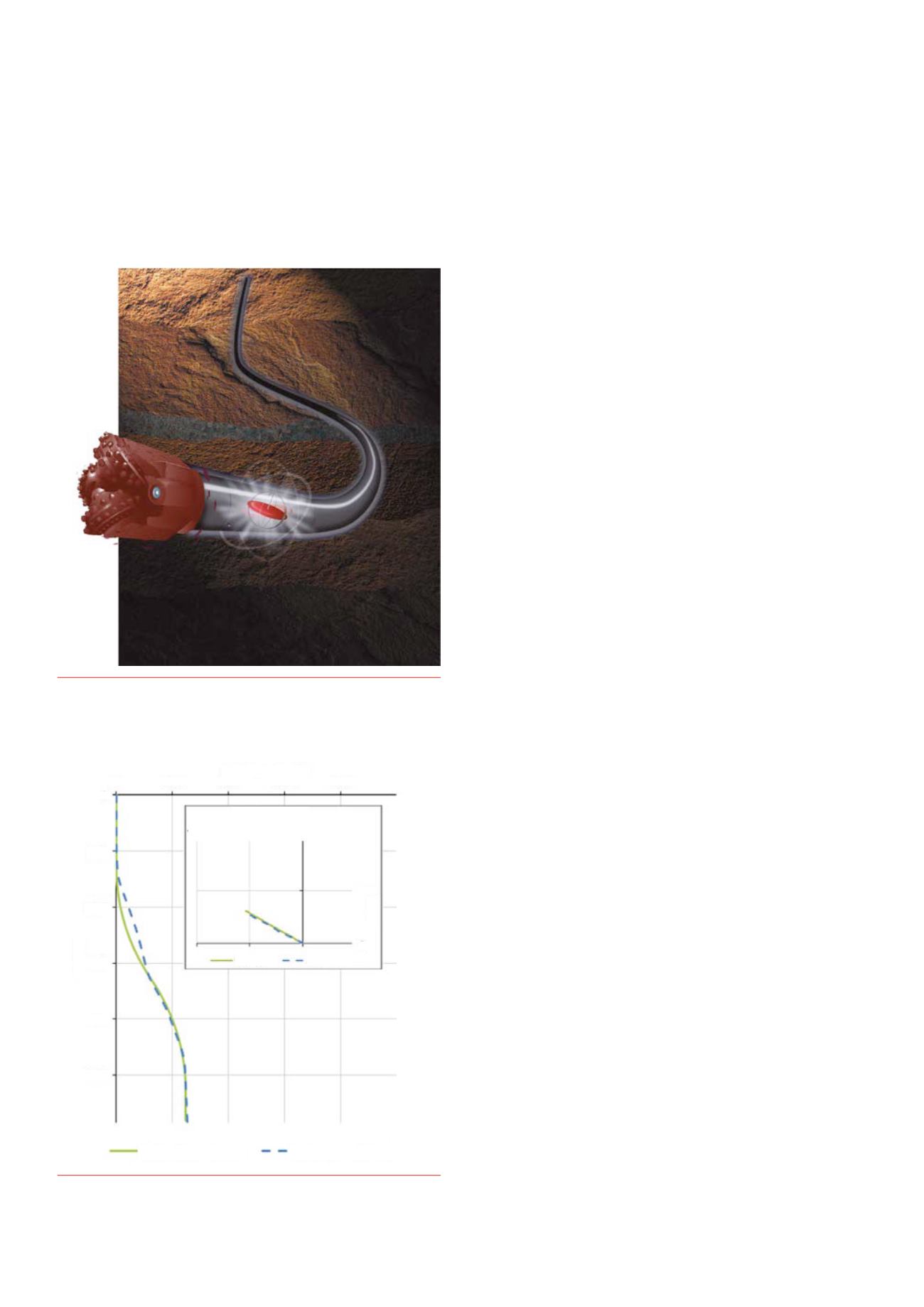

Figure2.

Well1,anS-curvedirectionalwelldrilledtonearly3000ftTVD,

wasdrilledunderacornfieldwithoutdisruptingtheharvest.

VerticalSection(ft)

0

0

500

1000

1500

2000

500

1000

1500

2000

2500

NS(ft)

-1000

500

0

WellPlan

SectionView-Planned

SectionView-AsDrilled

Asdrilled

PlanView

TVD(ft)

E-W(ft)

-500

0