30 |

OilfieldTechnology

February

2014

phenomenon, generating shockwaves and pressure. The

mechanical power generated is used for the destruction

and transport of disintegrated rocks away from the area

between the arc and the rock.

Ì

Ì

The system allows the generation of pressurewave

mode and pulsedmagnetic field increasing the power

of generated current pulseswith a transformation in the

time of charging/discharging from four to seven orders

of magnitude (s/

μ

s), thus allowing an increase in the

instantaneous pulse disintegration effect with power

pulses in the scale of MW or GW.

Wellstabilityenhancement

ContiCase is an innovative technology forwell stability

enhancement thatworks inparallel to thedrillingprocess

– essentially creating casing in‑situ, whiledrilling, in the

drillingbit zone, ensuringmechanical stability of thewell at

all times. It is composedof a set of technological processes

that enable the creationof anear‑net shapedmetal

structure. The ITF‑facilitated feasibility project assessed the

economy and effectiveness of theprocess and evaluated the

material’smicrostructure andmechanical properties aswell

as exploring thepotential for enhancing theproperties of

ContiCase structures through the use of addedmaterials to

create aprocess thatwill form layers on thewalls of thewell.

Theapproach couldbeparticularly valuable in

unconsolidated rock formations, which canbe challengingwith

respect tohorizontal drilling, andalsooffers thepossibilityof

a reduction innon‑productive time, as it is aone‑stepprocess

undertaken simultaneouslywithdrilling. Other benefits

andapplications of this technology could include the repair

and strengtheningof existingboreholes,management of

casingwith respect to variations in thickness and strength,

well stability combinedwithopenholeproductivityand the

productionof permeable casing sections in thewellbore.

Use of this type of well stability enhancement technology

couldpotentially have amajor impact inonshorewells, but

couldhave even greater benefits for offshoredrilling. The

aim is todevelop a system thatwill be suitable not only for

usewith theplasma‑baseddrilling technology, but also in

combinationwith current rotary‑baseddrillingmethods.

Realtimedataacquisition

ThePLASMABIT system, which is basedon the introduction

of an electric arc to the rock, offers the optionof optical

emission spectroscopy, which canbe used as theprimary

diagnosticmethod for evaluationof

rock composition.

Rockdisintegration is achieved

by interactionwith the high

temperature electric arc. Themelted

and evaporated rock elements are

highly excited and emit lightwhich

is converted into a spectral pattern

that canbe used to characterise the

chemical compositionof aparticular

drilled substance. The spectrometer

software enables rock typedetection

tobeperformedby comparisonof

themeasured signal with sampled

dataof a known andpreviously

measuredpatternof rock composition

(fingerprinting).

The system canbe used to identify thepresence of

selected elements, preciousmetals or other valuable

resources, such as hydrocarbons, throughdetection

of characteristic spectral lines in combinationwith

algorithms, plasma‑generator control and resource spectral

linedatabases. It alsooffers a route to theprovisionof

information about composition in every part of theborehole,

continuously in real timewhiledrilling, andoffers the

possibility of performing online spectroscopy inharsh

andhighpressure environments at highdepths inside the

borehole.

Thejointindustryproject’sfuture

Themain goal of theplasmadrilling researchproject as a

whole is commercialisationof PLASMABIT technology based

onhigh energy electrical plasma andmanageable in‑situ

well stability enhancement. This in turnwill deliver reduced

drilling costs and associated capital expenses, aswell as

improvedoil recovery arising fromwellbore stability. Similar

tomany joint industry technology development projects,

the scope of development consists of several phases. For

PLASMABIT, the first two yearsweredesignated for the

technology development andprototyping and subsequent

phases are oriented todrilling enhancement, ContiCase

integrationwith thedrilling system, interoperability, field

tests anddifferent application areas deployment.

InMay 2013, GADrilling successfully concluded the

feasibility study facilitatedby ITF, which aimed to evaluate

thepossible application andproperties of theContiCase

technology and to set up theproduct’s development project

plan and roadmap.

The target solution shouldbring increasedROP and a

remote controlled casing‑while‑drillingprocess, delivering

enhancedwell stability for unconsolidated rockdrilling

and/or borehole repair. The ultimatebenefit of thiswill be

an improvedoil recovery factor thanks towellbore stability,

especially indifficult rock formations.

InSeptember 2013, phase twowas launched inco‑operation

with threeoil andgasoperatingcompanies, onedrilling service

companyandoneequipmentproducer. Thisphasecombines

both theContiCaseandPLASMABIT systemdevelopment;

themaindeliverableexpected inFebruary2014 isadrilling

infrastructure formore than30ftdepth. Therearea few last

slots forparticipation in theproject foroperatingcompaniesand

drilling servicecompanies thatmaybe interested in joining.

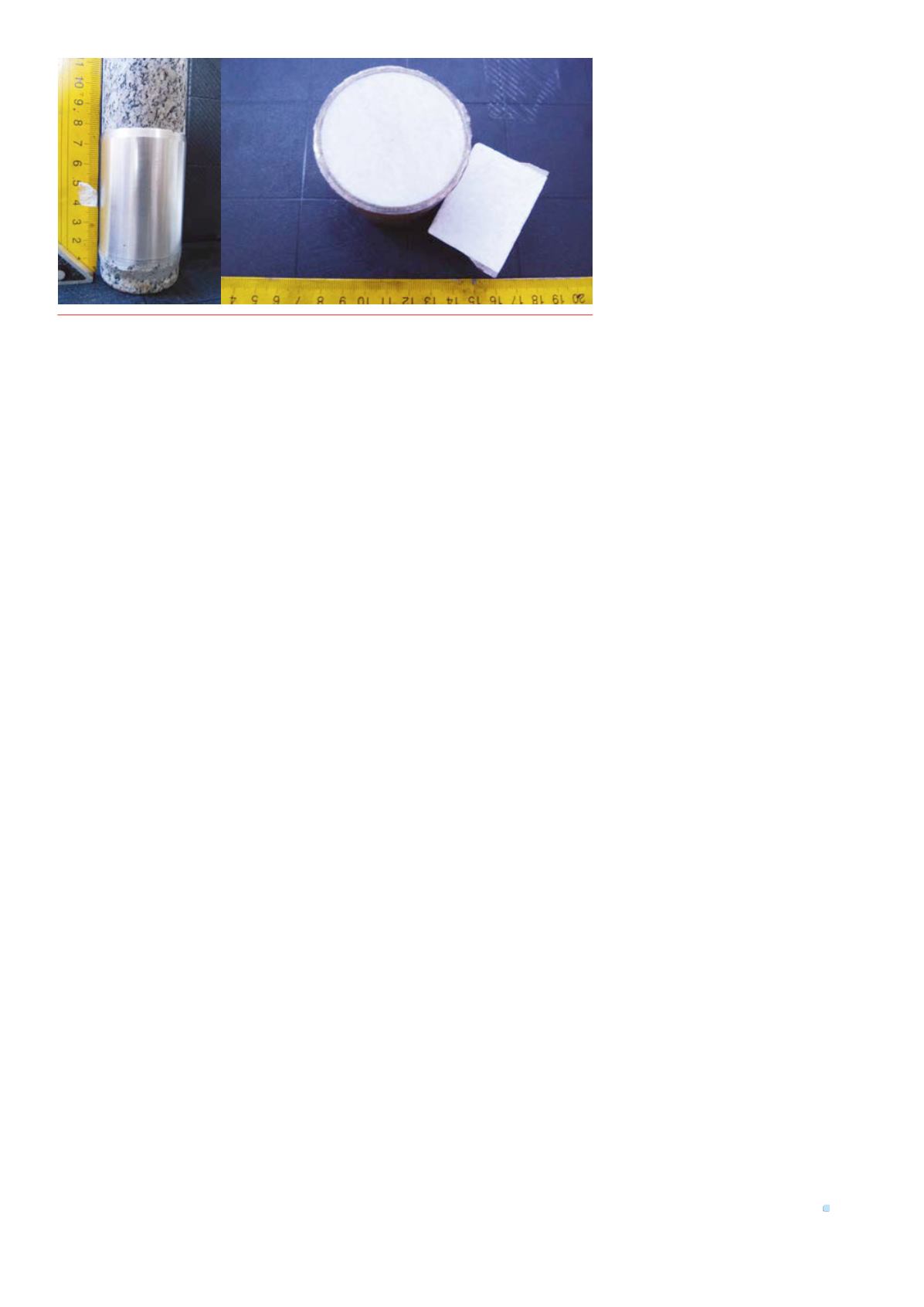

Figure3.

ContiCasesamplescreatedonannulargranitestructureformechanicaltests. Inthedrilling

industry,thistechnologywillbeusedon innerwallsofwellsfortheir immediatestabilisation.