38 |

OilfieldTechnology

February

2014

Thekeystatisticsof thewellsdrilledareshown inTable1.

Overall, thecampaigndemonstrated that thePOLARIS tool

is capableof directional andhorizontal drillingofwellswithhole

sizes ranging from6.25 in. to8.5 in., usingmudandanairmist as

adrilling fluid,whilst showcasing theabilityof itsAcrobat

gyro

system. This is the first time that a solid-stategyrohasbeenused

fordirectionalmeasurementwhiledrilling, providing reliabledata

at all inclinations (vertical, horizontal andduring thebuild section),

allowingorientation tobecarriedout accurately, evenwhile in the

casing.

Italsoprovidesevidenceofoperationalbenefits that

make itpossible foroperators todrillwells inshallow reserves

cost‑effectively,withminimal environmental impact.Precisewell

planscanbe followedandwellpathscanbeoptimisedbykicking

offearly (with thegyrostillwithin thecasing) reducingbuild rates,

making iteasier to runcasing.

Thesuccessof thiscampaigncamedown to threekey factors: It

wascarriedoutbyanexperiencedCTD teamwith thePOLARIS tool

andhybriddrilling rig. Thehybrid rig isacritical element.Hybrid

drilling rigsarehighlyadaptable, capableof runningCTand jointed

pipe, inaddition to runningandpullingcasing.Due to theiradaptable

nature,CTDoperationscanbecarriedoutwithasingle rig, greatly

reducing timeandcost. StudiesaboutCTD indicate thatdrilling times

are reducedby30% to60%, incomparisonwithoperationscarried

outwithstandard jointedpipedrilling rigs.

WhendirectionalCTDisbest

Coiled tubingdrilling iswidely recognisedas thebestway todrill

underbalancedwithina reservoir. Add to that theability todrill

directionallywith largerholesizesand thecapabilityenvelopestarts

toexpand.Hybrid rigscandrillwithbothcoil and jointedpipe, aswell

as runcasing, furtherenhancingefficiency levels. Fieldspreviously

deemed tobe tooexpensive toexploit cannowbeaccessedmore

economicallyandefficiently.

CTD isbestused indevelopmentand re-entryprogrammeswhere

thegeologyand reservoir conditionsarestraightforwardand familiar.

CTD isnotwell suited towildcatdrillingprojectsorone-offprojects

where thespeedandefficiencybenefitsdonothave time tocome

intoplay inasignificantway.

Phase1of theNiobrara campaign capitalisedon thePOLARIS

tool’s ability to target aprecise locationwithin the reservoir

without theneed toposition the rigdirectlyabove the target. In

Phase2, AnTechutiliseddirectional CTD toair-drill a reservoir

thatwas unable toeasily support a liquid column. This is an

ideal exampleof anapplicationwhereCTDhas anadvantage.

Alternativemethodswouldhave requiredagreat deal of drilling to

be carriedout.

Aswell as theapplications illustratedby theNiobraracampaign,

directionalCTD is recommended for the following:

Ì

Ì

Drilling in–or incloseproximity to–busy residential,

commercial or agricultural areas that necessitateaminimal

environmental footprint.

Ì

Ì

Drilling severalwells froma singlepadusing thegyrocapability

toavoidcollidingwithotherwells.

Ì

Ì

Drillingmultilateral branches from themainwellbore.

Ì

Ì

Drilling in sensitive reservoirs thatwould suffer excessive skin

damagedue tooverbalanceddrilling.

Thefuture

Whatdoes the futurehold fordirectionalCTD?Thesuccessof the

Niobraraprogrammedemonstrates that thePOLARIS tool –hybrid rig

drillingcombinationcanhelpmeetmarketdemands foraneconomic

andefficient solution. Thecurrent lownatural gaspriceshave

affectedactivity in thisarea,but therearestillmanydepletedoilfields

that couldbenefit from this typeof intervention.

CTDhasgained strongacceptanceover thepast 20years in

particular areasof theworld. Theopportunityhasnowcome to

broadenmarket acceptance; aprocess that canbe facilitatedby the

availabilityof newCTD technology.

Figure3.

TheAnTechteamputsthefinaltouchesonthecablehead

assembly.

Table1.Well data table

Well 1 Well 2 Well 3 Well 4 Well 5

Depthof casing shoe (ft)

500

325

350

365

336

Measureddepth (ft)

3030 1800 1467 2270 1884

Truevertical depth (ft)

2918 1520 1101 1090 1096

Maximumbuild rate (˚/100 ft)

13.5

19.6

15.3

15.8

15.9

Hole size (in.)

6.25

6.25

6.5

8.5 (intermediate);

6.25 (horizontal)

Horizontal offset (ft)

633

785

727

1452 1103

Dataproducedduring the five-wellNiobraradrillingprogramme indicates that awide

rangeofwells canbeefficientlydrilledwith thePOLARIS tool.

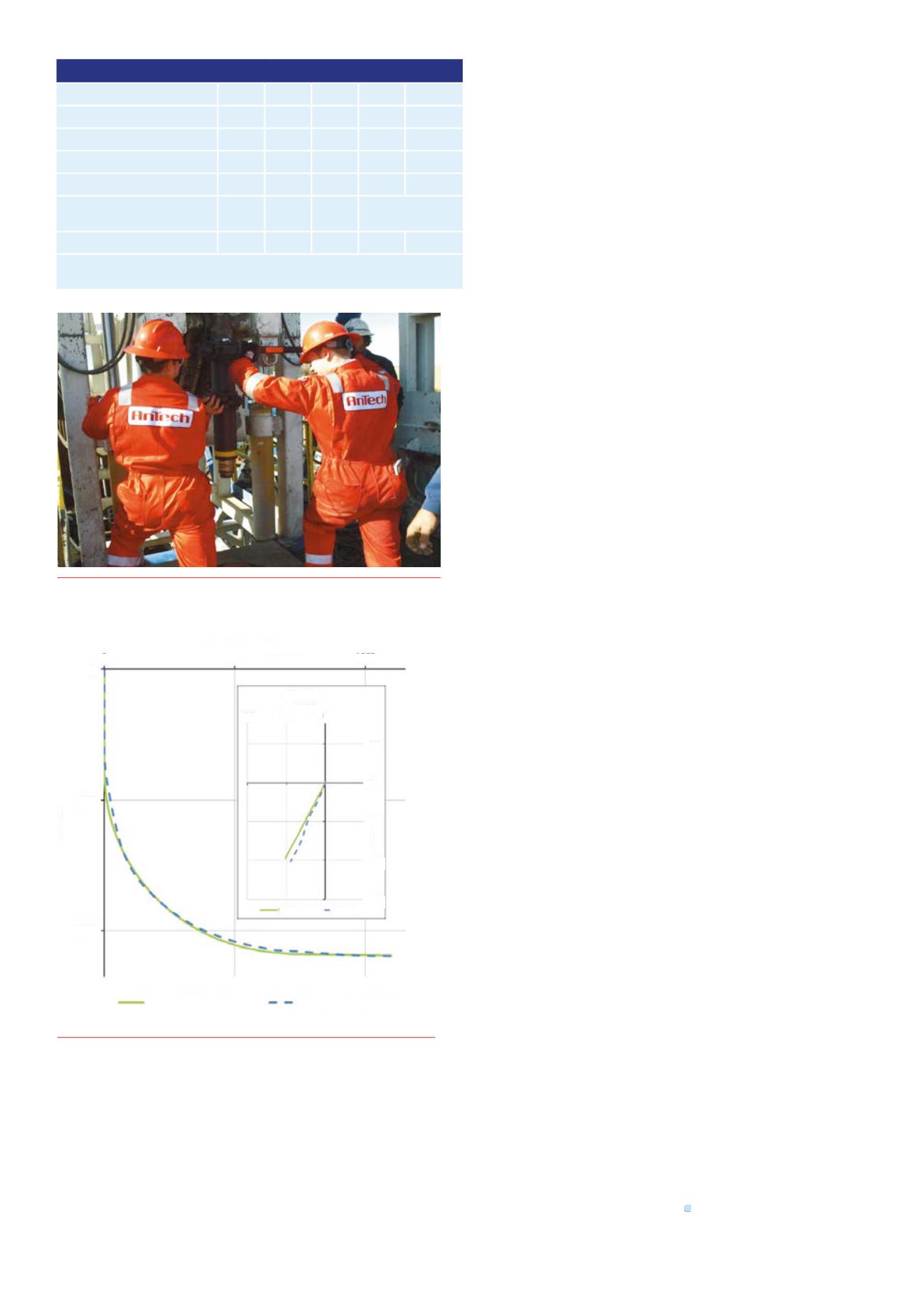

Figure4.

Well5drillingprofile.

VerticalSection(ft)

E-W(ft)

0

0

500

1000

500

1000

NS(ft)

-1000

-500

0

500

0

-500

-1000

-1500

WellPlan

SectionView-Planned

SectionView-AsDrilled

Asdrilled

PlanView

TVD(ft)