32 |

OilfieldTechnology

February

2014

Technologyadvancements:Electromagnetic(EM)

MWDsystems

Onearea thathas receivedquitea lotof attention is thedevelopment

ofnewMWDsystems foruse inunconventionalwells. EMSystems

offerpotential advantagesovermudpulsesystems in twokey

areas: system reliabilityanddata transmissionspeeds.Reliability

isalways thenumberoneareaof focus, however, additional focus

isondata transmissionspeed forgeologicalmeasurementsand

eliminationof survey times.Reducing thecost todrill thewell

continues tobeamaindriver foroperators involved indeveloping

unconventional resources. Asa resultwehaveseenan increase in

theusageofEMMWDsystems throughoutNorthAmerica. Although

prevalent inCanada forquitesome time, prior to2009 themajorityof

MWDsystemsused in theUS landmarketwerepositivepulsesystems

thatprovidedonlysurveyandgamma information. EMsystemswere

typically limited toapplicationswheremudpulsesystemsdidnot

workatall suchasairdrilling inunderbalancedor coalbedmethane

applications.

Reliability

EMMWD toolsalsoaddress twoof themajorareas thateffect

MWD reliability. Firstly, eliminationof themovingparts thatare

required foramudpulse tool tooperate isprobably the largest

factor. Aswithanysystem, a reduction in thenumberofmoving

partspositivelyaffectssystem reliability.WithanEMMWDsystem

themovingpulserparts, suchas thevalveandsolenoidormotor,

are replacedwithastationaryantennasystem. Secondly, all

mudpulsesystemsareverydependenton theconditionof the

mudsystem that isbeingused todrill thewell. Thebiggest issue

formudpulsesystems, besidesadequate flow rate, isdebrisor lost

circulationmaterial (LCM). In theUSmarket inorder todevelop these

unconventional reservoirs thebitmustpass throughpreviously

producedandsubsequentlydepleted reservoirs. Inorder tosafely

drill thesewells largeamountsof LCMare required tobeadded to the

mudsystem toprevent fluid losses to the formation.

Improveddatarates

Asopposed tomudpulseMWDsystems,which relyonmud flow

to transmit thedata fromdownhole to thesurface, EMsystems rely

on low frequency, highpowerelectromagneticwaves transmitted

from thedownhole tool and receivedanddecodedat thesurface.

Utilising theEMsignal to transmitdataversusmudpulsedata

enablesasignificant increase inoveralldata rate. Standardpositive

pulseMWDsystemsused in theNorthAmerica landmarketare

capableof transmittingat ratesof slightly less than1bitper second

(BPS).On theotherhandEMMWDsystemsarecapableof

transmittingat rates20 timesgreater than this.

Prior to2009 the relativelyslowdata rates inherentlyassociated

withmudpulsesystemswereperfectlyacceptable formost

applications. In thecaseofunconventionalswherecontinuous

surveyand logging informationare requiredat veryhigh ratesof

penetration (ROP) thesedata ratesareno longeracceptable. This is

especially trueasadditionalmeasurements to theMWDsystem toaid

inwellboreplacementanddrillingefficiency.WithanEMMWDsystem

data ratesof 10 - 20BPSarenowachievable,whichenableshigh

levelsofdata transmission fromdownhole to thesurface.

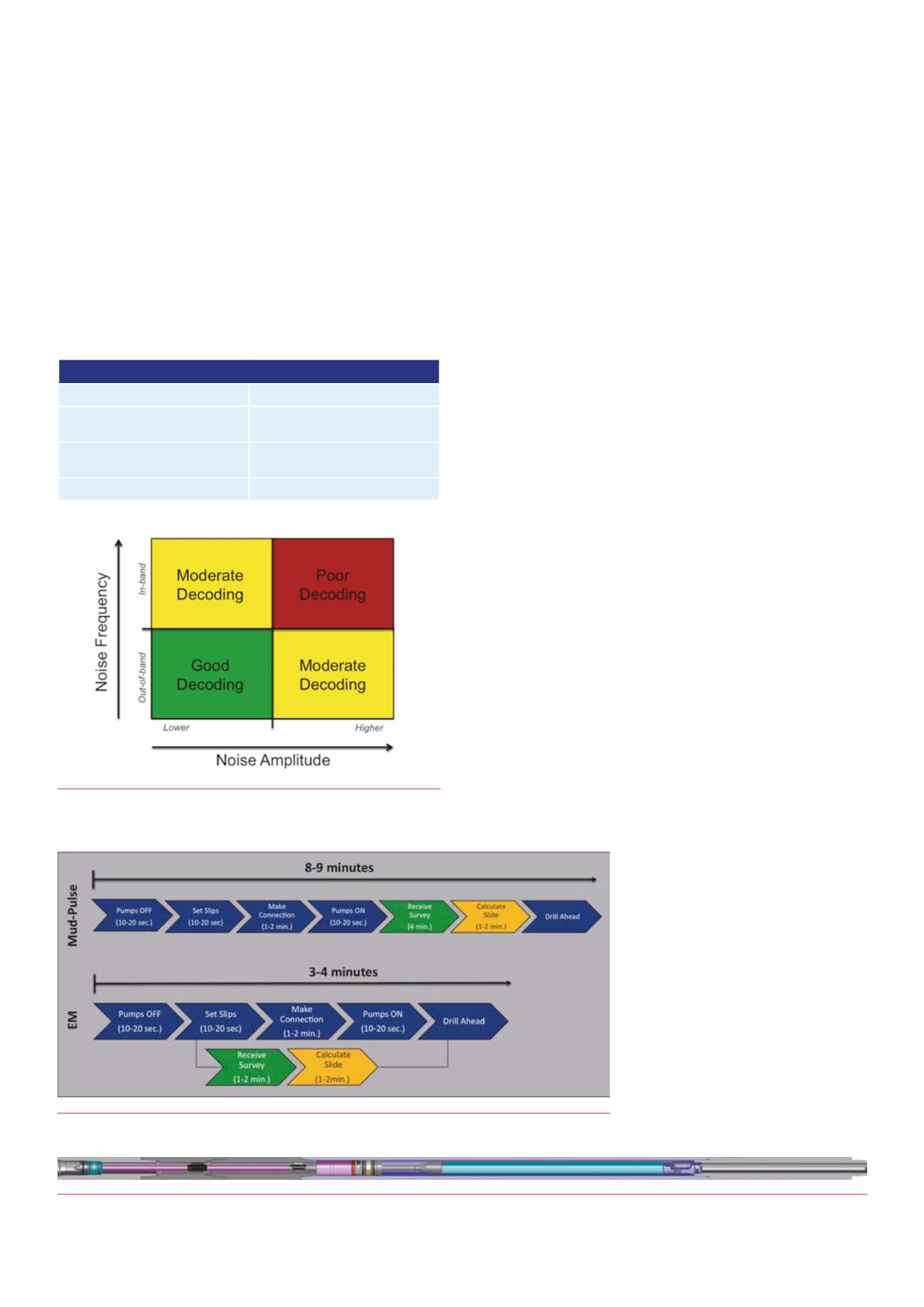

LimitationsofEMMWDsystems

All EMMWDsystemsare relianton the

conductivityof theearth to transmit

thesignal to thesurface, therefore

performanceof thesesystems is limited

togeology,whichwill vary frombasin

tobasinandoften location to location.

TheEMsignaldecreasesas thedepth

of thewell increases, asa resultof

increasedcumulative resistivity in the

earth. Additionally, thesignal strengthat

surface is relativelysmall and therefore

another challenge forEMMWDsystems

isbeingable tooperate inhighelectrical

noiseconditions. Theelectrical noise is

createdby thedrilling rig. Improvements

Figure1.

Effectofnoiseamplitudeandfrequencyondecoding

performance.

Figure3.

TheRyanAccuWaveEMMWDsystem.

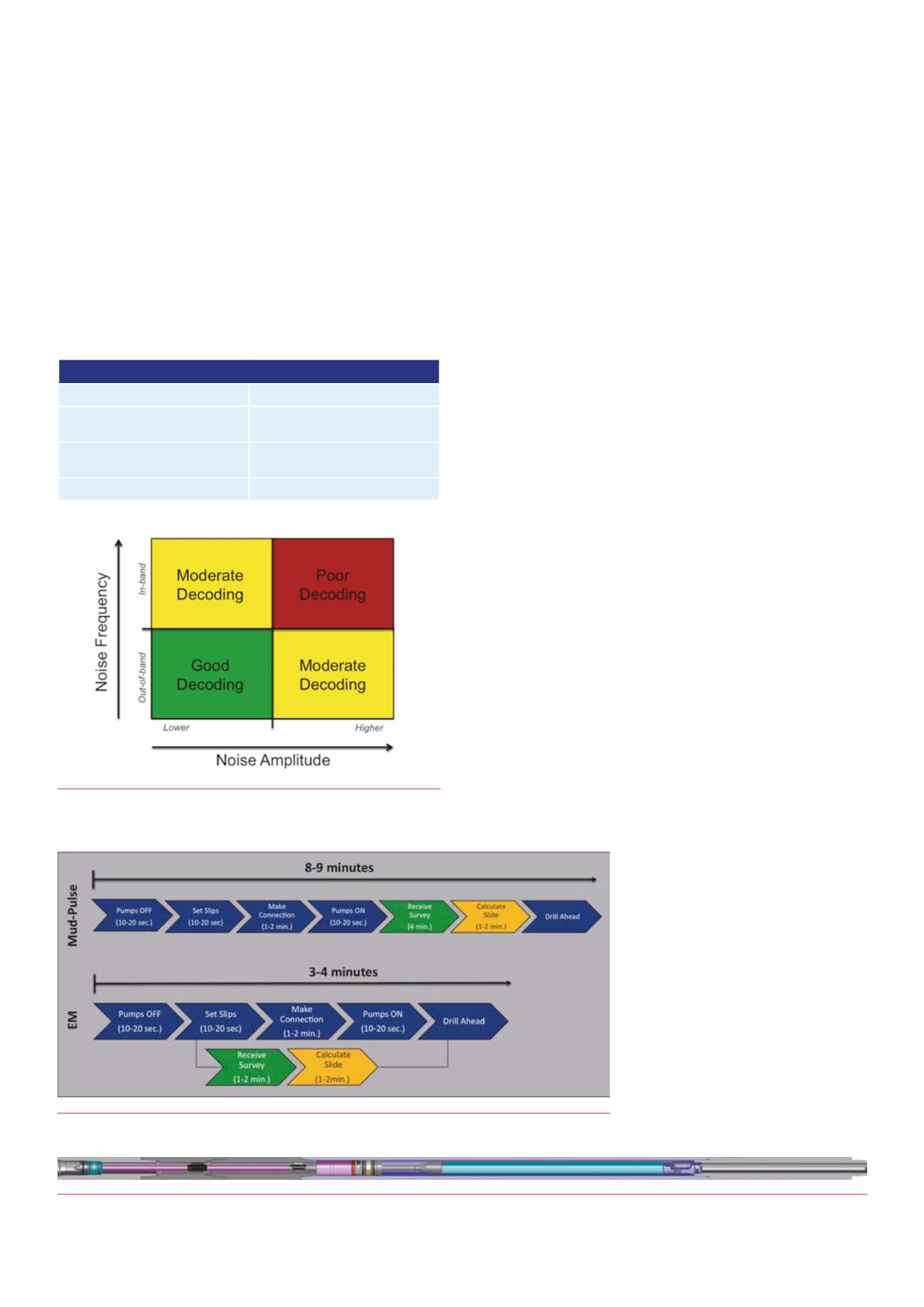

Table1. Time savingsattributed toEM tool usage

Activity

Rig time savings

Eliminationof survey timeat

connection

Average4minutesper survey

DDon rig floor tobegin slidingat

pumpson2minutesper slide

2minutesper slide

Eliminationof check shots

4minutesper check shot =1hour

Figure2.

ChartcomparesthetypicalsurveysequenceMudPulseversusEMMWD.