completely replaces the primary flow at shut off. Interestingly, to be

sustained, the secondary flow requires almost as much power as the

primary flow, as the input power curve in Figure 2 shows.

Second, numerical simulation processes become stable at flows below

20% of maximum because the solution is continuous and unique and,

therefore, computational fluid dynamics (CFD) codes can accurately predict

the solution. In other words; the transition from primary flow to secondary

flow happens in an orderly and continuous way such that CFD analysis can

fully capture.

CFD codes, on the other hand, cannot predict solutions for

compressible flows (0.1 < M < 0.3) in the vicinity of shut off due to

discontinuity in the solution, the pressure rise curve measured when the

flow is decreasing may be different from the pressure rise curve

measured when the flow is increasing (from 0 to 20%), this

non-uniqueness is called hysteresis. In fact, if LNG is replaced by a

compressible fluid (such as air or light hydrocarbon with very low

specific gravity, M > 0.3), then there will be a lower limit on flow, called

the surge point, below which a stable solution does not exist, and near

which CFD numerical simulations would breakdown.

Conclusion

Centrifugal pump optimisation can be achieved by utilising inducers with

avocado shaped hub contours, impellers and diffusers with circular arc

blades, and preferred functional parameters. To meet different flow and

head requirement, centrifugal pumps can be geometrically scaled and

their performance accurately predicted. Incompressibility of LNG

renders it conducive to numerical analysis over the entire flow range, as

the consumed power is utilised to sustain mean flow, secondary flow, or

both. ACD is developing proprietary software to predict performance

curves of new pump designs utilising optimum design parameters, test

database of production pumps, scaling and gulping of existing hardware,

CFD codes to calibrate and enhance software accuracy, and an

embedded warning system to alert the user when fluid/thermal/

structural parameters deviate from allowable ranges.

Vacuum Systems

Process-integrated solutions for

many types of vacuum system.

More than 80 years of ex-

perience in the development,

design, and construction of

steam ejectors and hybrid

vacuum systems.

Thousands of references in

numerous industrial sectors all

over the world

.

engineering for a better world

GEA Process Engineering

GEA Wiegand GmbH

Phone: +49 7243 705-0

Internet:

GJP4e14

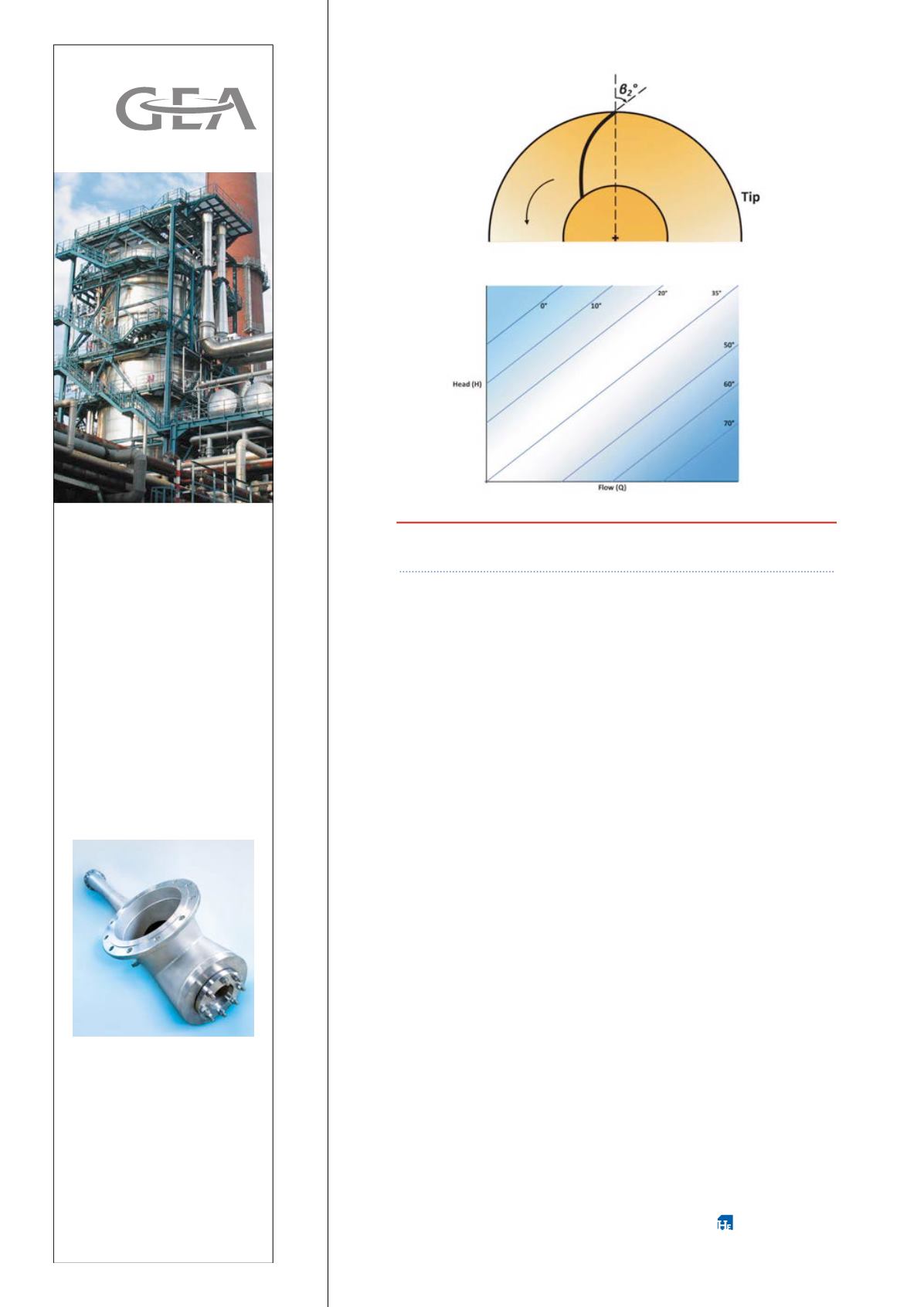

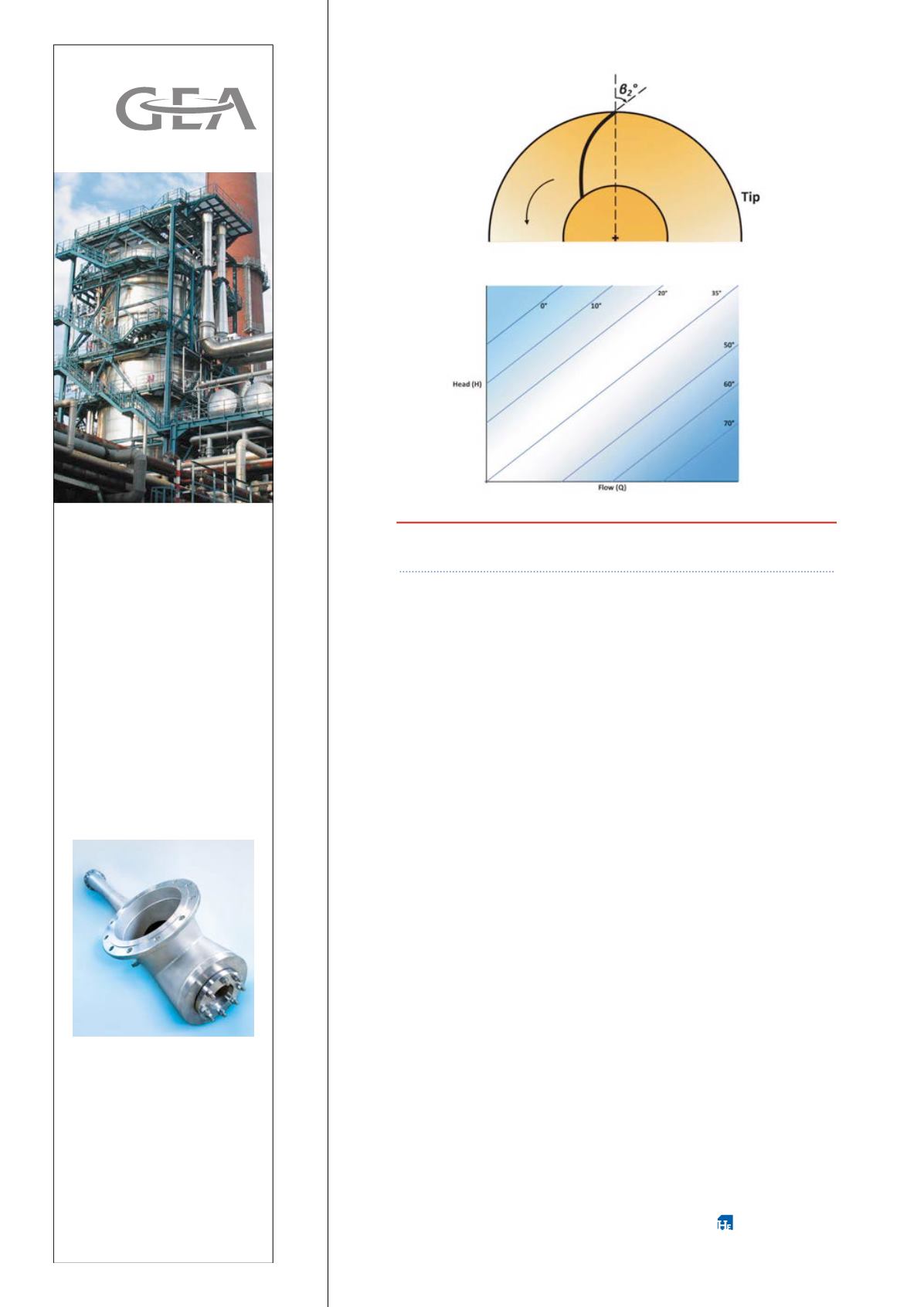

Figure 4.

Contours of preferred blade tip back sweep angle

(Beta2).