without having some idea as to what it may cost if one

decides to move forward. What is being proposed is that one

needs to spend the majority of one’s time focusing on the

benefits, and value that the software can deliver before taking

the ‘deep dive’ into determining the final cost of

implementation and final ROI. It is better to look at total cost

in light of what one will get for the outlay instead of looking

at what you can get for a certain spend.

Surviving the demo

It is not a mistake that the subject of the software/solution

demo has been left to the end of this piece, and that is

because that is where it belongs. Often when a software

solution is being looked at one of the first things that is

requested is a demo, and often based on the ‘performance’ of

the person doing the demo most of the buying decisions are

made. This is not the best approach.

In basing a decision on what is known in the industry as a

‘dog and pony show’ i.e. a circus act, is not the best basis for

the selection of a software solution, and especially something

as complicated and enterprise impacting as a plant design and

engineering solution. Please do not misunderstand, a client

will need a demo and it should not only be thorough, but it

should help answer questions as to ‘Can it deliver?’ That

means that having someone demonstrate the solution until

one sees something that one likes, or even dislikes, is not

productive. A solution may be rejected because the

demonstrator was just not on that day. The author has been

that demonstrator, and is certain because of that misstep the

prospect in that case ended up with the wrong solutions.

The better way to use the demo is to have the software

company demonstrate that they can do all that has been

agreed can be done. In some cases, with more complicated

solutions, which may need customisation, have them

demonstrate how what is needed can be arrived at, and how

that will be done.

Remember, eyes on the prize, the idea is for them to

demonstrate the capability of the software to do what is

needed, not to catch them out, or for them to provide

entertainment.

Conclusion

There is a lot of good software out there, created by teams of

dedicated individuals that passionately care about what they

are doing and how they will effect the lives of those that put

their trust in what they are creating. Take the time to evaluate

as many vendors as possible and also take the opportunity to

find out what others are doing and why they have made the

decision to select one vendor’s offering over another. The

reading of success stories can be particularly enlightening as

they can often offer insight into an end users situation, the

problems that they faced, how they solved those problems

and what their pay off, or value was from deploying a solution.

All the above may seem complicated compared to

someone coming in and doing a demo, but if the steps above

are followed, one will be more assured of success than if more

‘traditional’ ways of selecting a solution were used. One will

know what one wants the software to do and will be less

surprised when it does not perform as slickly as when ‘that guy

did the demo.’

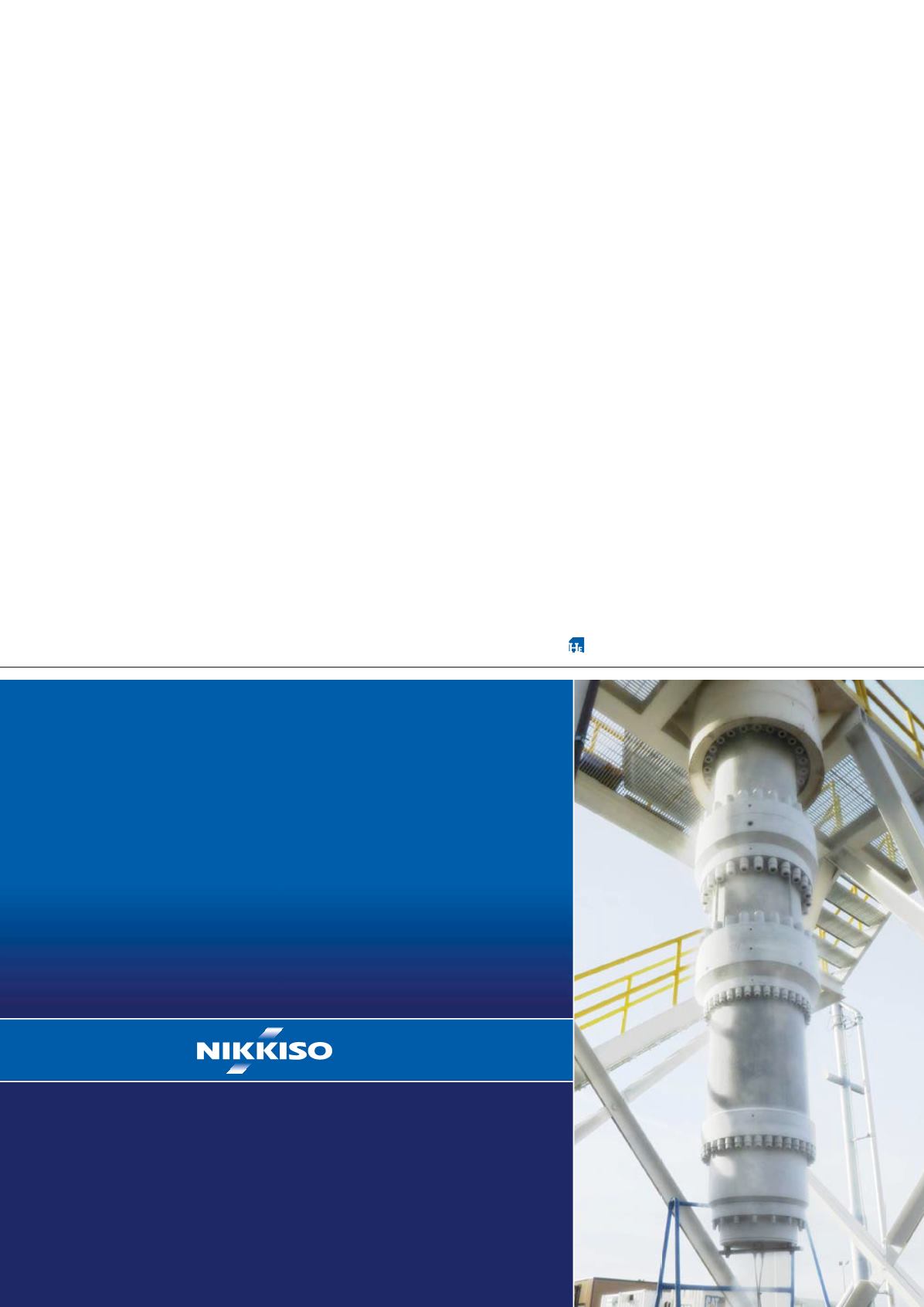

Global leader in development, engineering and testing.

Superior Reliability.

Full Range of Cryogenic Pumps.

• In tank, removable pumps for storage tanks.

• Vessel-mounted pumps for process systems.

• Fixed mounted pumps for marine or other applications.

Low total cost of ownership.

No shaft seals - maximize safety, with low maintenance costs.

Unparalleled quality.

Exceptional pump-down capability (low NPSHR).

• Global Headquarters with production and test facilities located in Las Vegas, USA

• Production & Test Facilities in Las Vegas, USA and Tokyo, Japan

• NCI is served by the Nikkiso and LEWA Worldwide network

• Over 1700 units operating in 618 facilities worldwide onshore & offshore

• Pumps for LNG/NGL/LN2/LEG up to 3000 m3/h of flow and up to 3000m of head

• Up to 25,000 hours Manufacturers Warrantee Over 25 years of Engineering Excellence

OVEr

25 yEaRS

OF ENGINEErING

ExCELLENCE

SUBMERGED MOTOR CRyOGENIC

PUMPS FOR LIQUIFIED GaSES