60

December

2014

HYDROCARBON

ENGINEERING

of dollars, will be based on what assumptions are established

here.

Creating an optimal workflow

During this process it may quickly become apparent that one

is developing a workflow that may not align with current

work practices, it may even seem like a fantasy, but that is

OK. If one is going to invest in a plant design or engineering

software solution, would it not be best if, instead of the navel

gazing and picking apart everything that is currently done,

one comes up with a list of things that one wishes it to

achieve?

For that a workflow needs to be identified that will give

the best chance of selecting the right tool. That workflow will

likely not be the one that is currently employed, but one that

would be an optimal workflow for the workgroup(s). Software

will not automatically make up for bad practices, but

deploying the right solution can make good practices better,

even if those practices are not even part of current work

processes!

If after the above exercise one discovers that best

practices are not currently employed and workflow is less

than optimal, one may feel that this method of defining what

one wants from a solution may be too risky. If that is so

please consider that defining what success will look like will

put evaluators well ahead of the majority of people that are

looking to optimise their plant design and engineering

processes. It is easy to fall into the trap of just wanting things

to be better than they currently are, but really is that enough?

If that is the case, it really does not matter which solution

one settles on, because the truth is that very few solutions

are so bad that they would not give you some degree of

improved performance.

Perspective, reality and fear

It will not be a surprise to hear that, given unlimited funds, and

time, software can be made to do almost anything that may

be required, but the reality is that neither resource is

unlimited, and every company needs to determine what they

absolutely must have, what would be nice to have, and what

they can develop workarounds for and, yes, what they can do

without.

The author has gone through many sales cycles, as part of

a purchase team, in sales support and also as a salesperson,

and one thing that is the worse thing that can happen, at any

point of the sales cycle, is when fear, on both sides, sets in. Do

not get the author wrong, a good amount of skepticism on the

buyer’s side is healthy, and concern on the seller’s side that

they are hitting all of the buyers main points, is also to be

expected. Even so, fear on the buyers side often comes from

not being sure that they are giving more than they will be

getting and that the solution will not measure up to the

salesperson’s promises.

As fear enters the equation the focus devolves into the

mitigation of risk and concentration on features. And with

that, gone are thoughts of the great things that the software

can do for the buyer and how it can make the buyer’s life

better. The thing is that the process does not have to be

fearful if the buyer can, at any point in the process, be sure

that they are getting a good deal, that they will see value in,

not only the software, but the long term relationship that the

implementation of the tool will entail. So as long as value is

assured, and is the continual focus on both sides, fear can be

replaced with focus.

Defining value

If one has read this far one may feel that something is missing,

and that this article, that seems to be dismissive of current

work practices and workflow, to help determine what a client

wants the software to do, is foolish or, at best, just plain naïve.

But there is actually great value in establishing current

workflow and it plays a large part in calculating the value of

implementing an ideal system, and removing the fear of

moving forward.

As mentioned earlier, current workflow should not be the

main factor in deciding what a client wants to achieve with a

software solution. But when used in conjunction with a

specific optimised workflow it is a great way to help

determine the following:

n

n

Inefficient work practices.

n

n

Where the software can help.

n

n

Where the software cannot help.

n

n

Team skill level.

n

n

Training needs.

n

n

Implementation requirements.

Value is the delta between where one currently is with

one’s current workflow, practices and tools and when

compared with where one wants to be with the solution

installed, and with a specific optimised workflow in place. ROI,

on the other hand, is the difference between the deployment

costs and that value.

So should the cost of the software be ignored? Well no,

not at all, it would be deleterious to go into this process

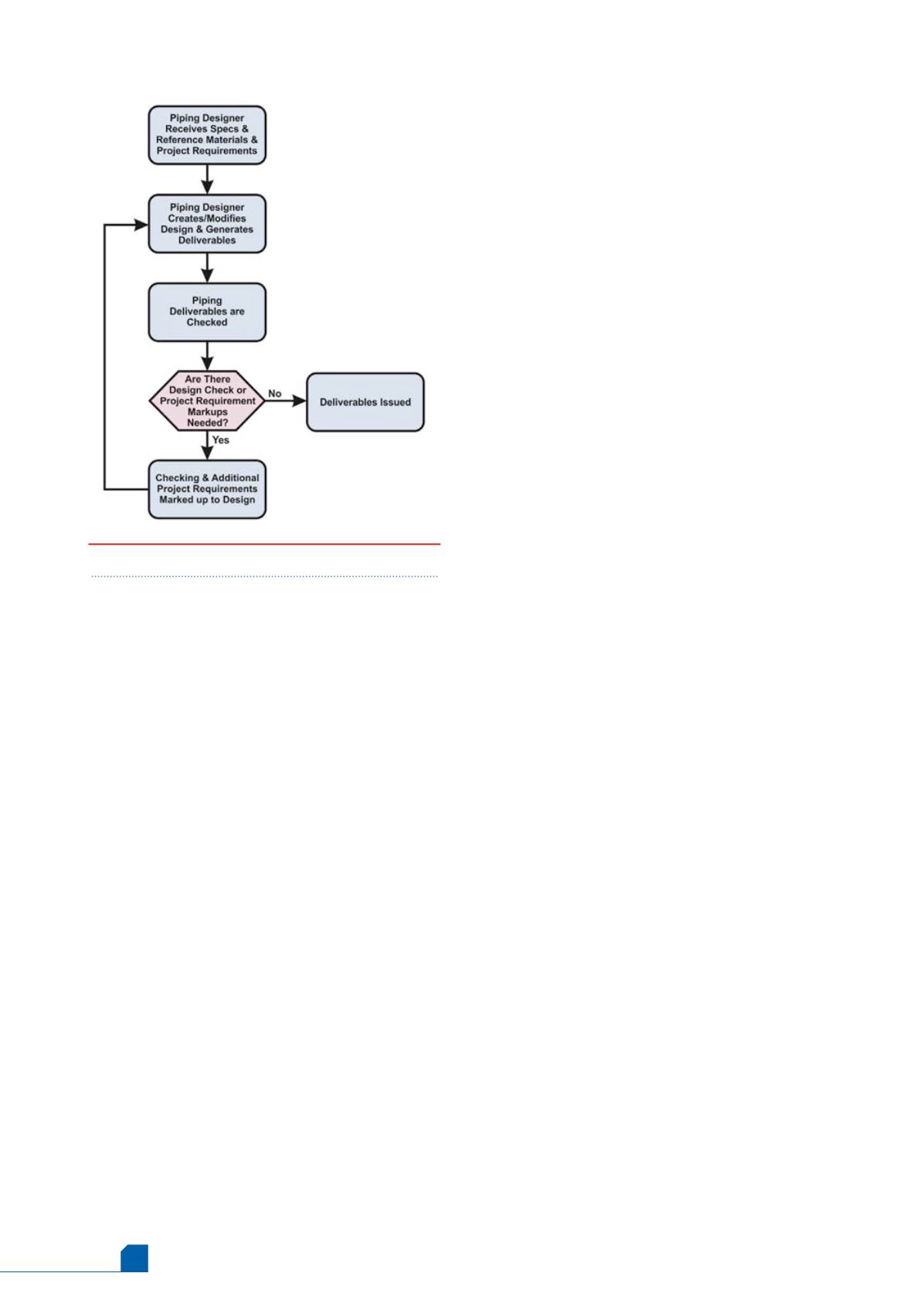

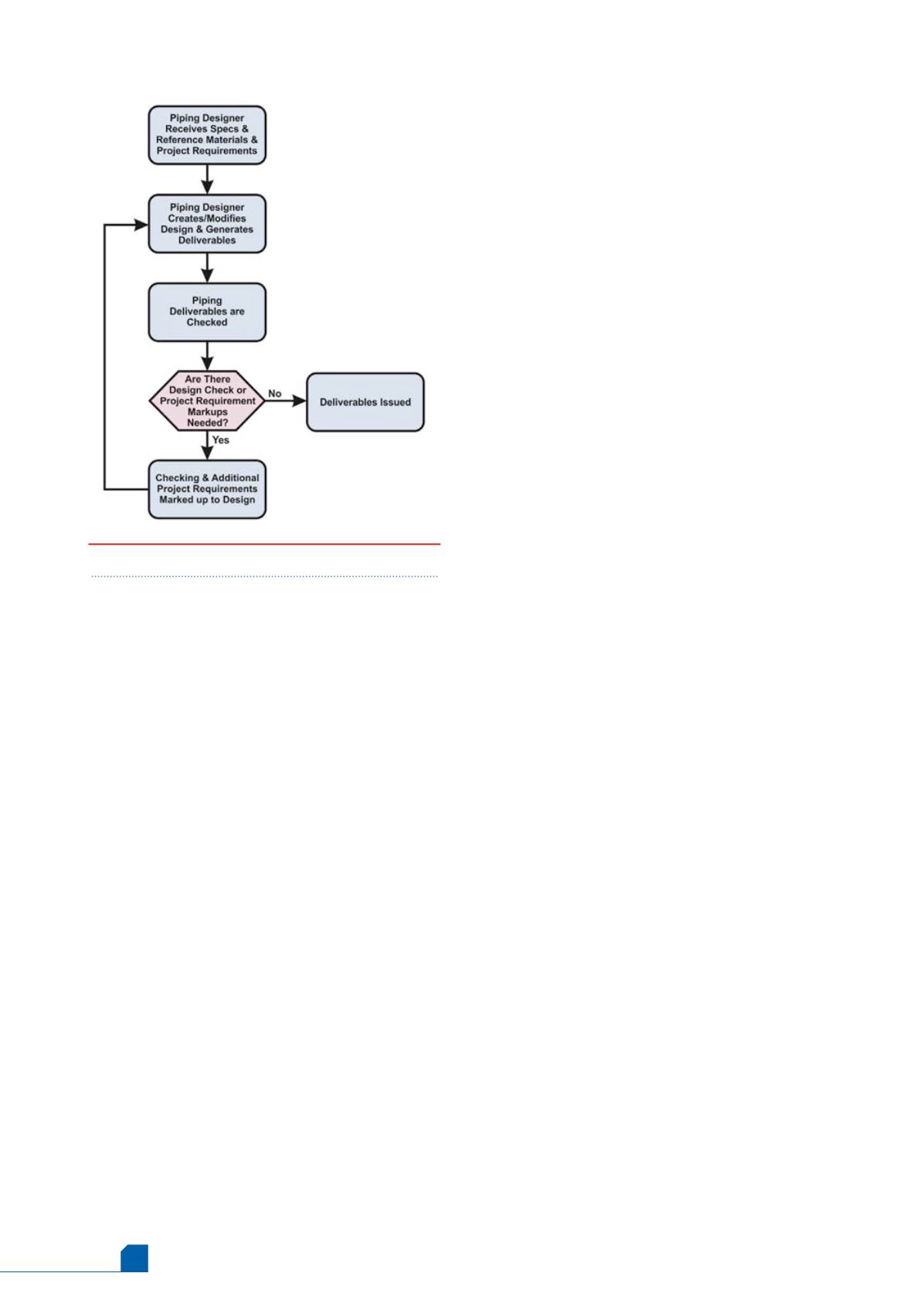

Figure 1.

Simplified piping design workflow.