50

December

2014

HYDROCARBON

ENGINEERING

thus cause bubbles to collapse prior to arrival at the

impeller leading edge. ACD has specific proprietary criteria

that provide the optimum magnitude of hub rise relative to

the inducer’s axial and radial extents. The avocado shaped

hub yields the correct balance between flow centrifuging

and flow turning. The blades are attached to the front

expanding portion, and not to the aft receding portion.

Solidity is defined as the blade chord (i.e. linear distance

between the leading and trailing edges) to spacing (at the

trailing edge) ratio. The blade angle is measured from the

axial direction and must be in the 70 - 80˚ range (or 10 - 20˚

from the tangential direction). Most of the pressure rise is

produced via the centrifugal effect, while the slight overall

turning along the flow pathways produces the remainder.

The small positive incidence, usually between 0 - 3˚, is

required so that the incoming flow strikes the pressure side

of the blade. This particular design aspect is more relevant

to performance than to hindering cavitation.

The preferred impeller profile

A high performance low cost impeller is characterised by:

n

n

2D circular arc shaped blade profile.

n

n

Velocity factor = 1.2.

n

n

Blade tip back swept.

n

n

Overall blade camber < 50˚.

n

n

80%/20% head production rule.

The two dimensional (2D, with no variation along the

axis of rotation) circular arc shaped blades offer low cost

tooling, and have been proven to be efficient for

incompressible flows such as LNG.

The velocity factor is the ratio of actual impeller tip

speed to the ideal fluid pumping speed; the latter = SQRT

(H), where H is the required stage head (H). The blade

camber angle is the magnitude of the overall turning (or

curvature). The optimum blade tip back sweep angle (Beta2,

against the direction of rotation) is shown in Figure 4 as a

function of head and flow; high head low flow pumps favour

near radial tip profile, but low head high flow pumps favour

near tangential tip profile. For moderate heads and flows

the ideal Beta2 is 35˚.

An efficient impeller would have approximately 80% of

its total head produced via the centrifugal effect while the

remaining 20% produced via flow turning within the

impeller channel; this balance is essential because the

centrifugal mechanism is very effective relative to flow

turning, the efficiencies of the two mechanisms are about

90% and 70%, respectively.

The preferred diffuser profile

A high performance diffuser profile is characterised by 2D

circular arc vanes with inlet angle about 72˚ (from radial, or

18˚ from tangential), outlet angle about 45˚, and solidity

between 1.0 and 2.0; the resulting overall blade camber

angle (or turning, the difference between inlet and outlet

angles) is 27˚. In general, the preferred vane camber angle

range is from 20 - 40˚.

Consequences of fluid

incompressibility

LNG is an incompressible liquid because its speed of

sound (C, the speed at which changes in pressure are felt

within the pump stage) is very high and the pump inlet fluid

velocity (V) is usually low; therefore, the Mach number

(M = V/C) is near 0.0, far below the level (M > 0.3) at which

compressibility effects become active. At reduced flows,

the incompressible nature of LNG has two fluid dynamic

consequences.

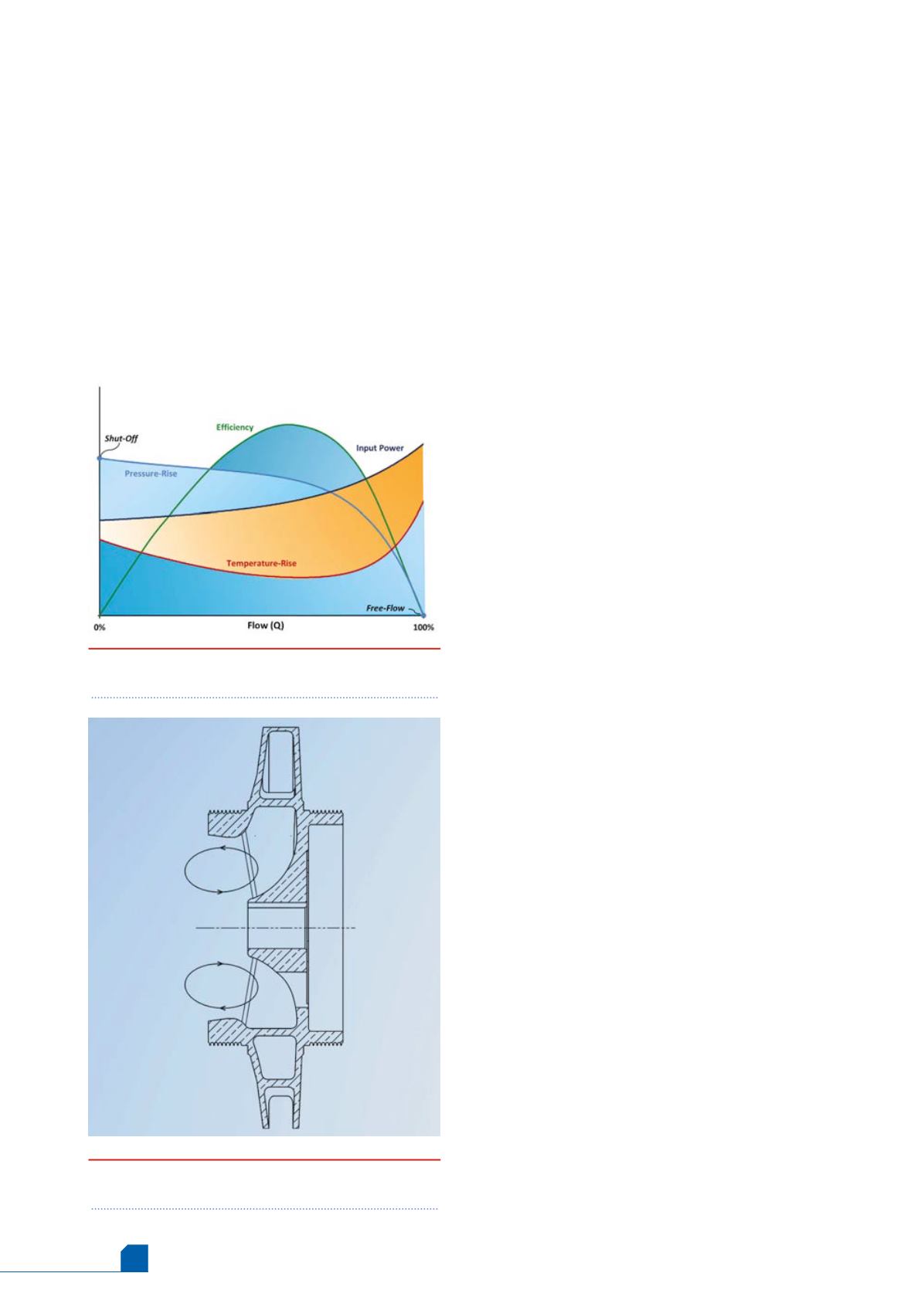

First, the process of redistribution of flow streamlines

becomes predictable because, depending on the flow

magnitude, one of two distinct flow patterns may emerge.

At high flows only primary flow persists across the stage.

But as the flow is reduced, secondary flow begins to form,

becoming more and more coherent towards shut off, and

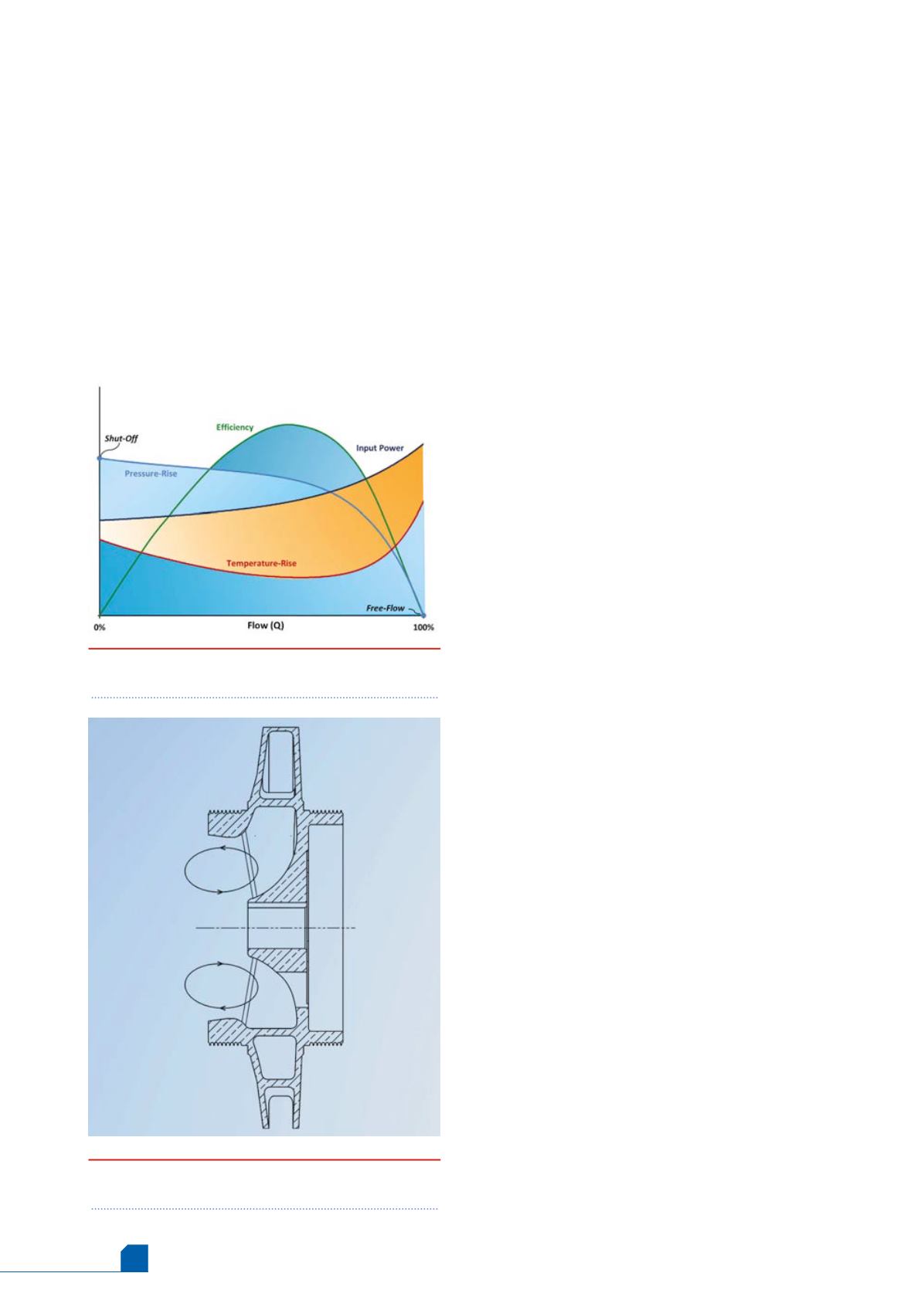

Figure 2.

Typical centrifugal pump performance

curves.

Figure 3.

Fully developed secondary flow

circulation at shut off.