50 |

Oilfield Technology

December

2014

steels (which tend to also attract a cost premium), as well as chemical

and erosion effects due to the proppants used.

Reducingfatigue

Fatigue cracking is generally initiated at areas of high stress

concentration, although this does not indicate yield and/or ultimate

tensile strength are governing factors of the steel. For instance, fatigue

cracking in steel can be instigated at approximately 50%of the yield

properties. With constant flexing of the stress area (such as in the case of

pressurising the fluid end), regions with stress concentration and surface

defects (e.g. machiningmarks) begin to work harden, eventually forming

micro cracks at the crystal boundaries. Continued flexing operation

propagates the cracking further until fissures are visible. At that stage, it is

only amatter of time before the component will fail.

Moreover, techniques have been specifically developed to reduce

fatigue effects, including autofrettage and shot peening. Both methods

provide localised, compressed surfaces within the internal structure

of the fluid end. Polishing the internal bores (particularly at the

cross‑section points) also aids in extending fluid end life. The smoother

surface (compared to a 63

μ

m surface machined finish) results in

decreased surface defects, thereby reducing areas in which fissures

can initiate. However, producing consistently polished surfaces can

be costly because of the significant time required to achieve desired

results.

Monoblockversusmodular

In regards to the overall design of fluid ends, two schools of thought are

currently pursued:

Ì

Ì

Monoblock design: Single, monoblock unit, comprised of a single

billet of material machined to the appropriate configuration of either

Triplex or Quintuplex.

Ì

Ì

Modular design: Interchangeable units comprised of singular fluid

ends and configured as a Triplex or Quintuplex assembly.

Replacement/repair

All bores in amonoblock design aremachined in one billet and the

pressuring function is carried out throughout the singular unit. However,

when fatigue cracking, erosion, or corrosion occur, the full unit must be

replaced/remanufactured, even if the cause is a single, problematic bore.

Turnaround time for repairs can span several weeks due to required

remanufacturing and testing processes. Operators are forced to endure

the resulting downtime on the pump unless considerable inventory costs

are allocated for maintaining sparemonoblocks.

Conversely, amodular design is focused onminimising potential

downtime by allowing for segmented replacements. With this approach,

the assemblies are created utilising singular fluid ends. Then, if one fluid

end fatigues, it can be replaced and the remaining cylinders continue

operation. Inventory options are alsomore viable, as interchangeable

fluid end segments aremore economical thanmonoblock fluid ends.

Additionally, downtime is potentially lower, as the failed fluid end is

replaceable within the assembly and the pump can be restored to

operating condition without delays for remanufacture.

Operatingconsiderations

Stresses and pressuring operations are contained within the singular

structure of themonoblock, resulting in interplay of stress distribution

across all bores. This may ultimately have a detrimental effect on the

fluid end’s overall structure. In contrast, themodular fluid end design

provides a natural break in stress distribution across the assembly.

The result is a reduction of inter‑fluid end reactions and stress transfer

between adjacent bores.

Versatility

Modular fluid end assemblies can be configured for complete

OEM replacement (i.e., all interfaces are identical to the OEM fluid end).

Operators are able to choose continued use of monoblock fluid ends

and/or modular fluid ends, depending on preference and specific

application. For example, flexibility may be preferred when known

operating conditions typically reduce fluid end life.

Maintenance

Regardless of design, a soundmaintenance programme will extend fluid

end life. Rather than mitigating pump issues as they occur, a thorough

maintenance schedule is ideal to ensure the longest fluid end life

possible. For example, it is beneficial to periodically assess fluid ends for

signs of wear and damage in areas such as the seals, check valves and

packing assemblies. The general condition of the fluid end bores should

also be examined for erosion, corrosion and/or fatigue cracking.

While specific inspection times cannot be dictated, a service

schedule or check is optimal after each frac stage, as well as whenever

feasible (e.g. during periods in which the pump is not in operation).

Proactivemaintenance aids in ensuring the fluid ends are not operated

until a fail condition that results in significant costs (especially if the

pump fails during a production operation, such as fracking).

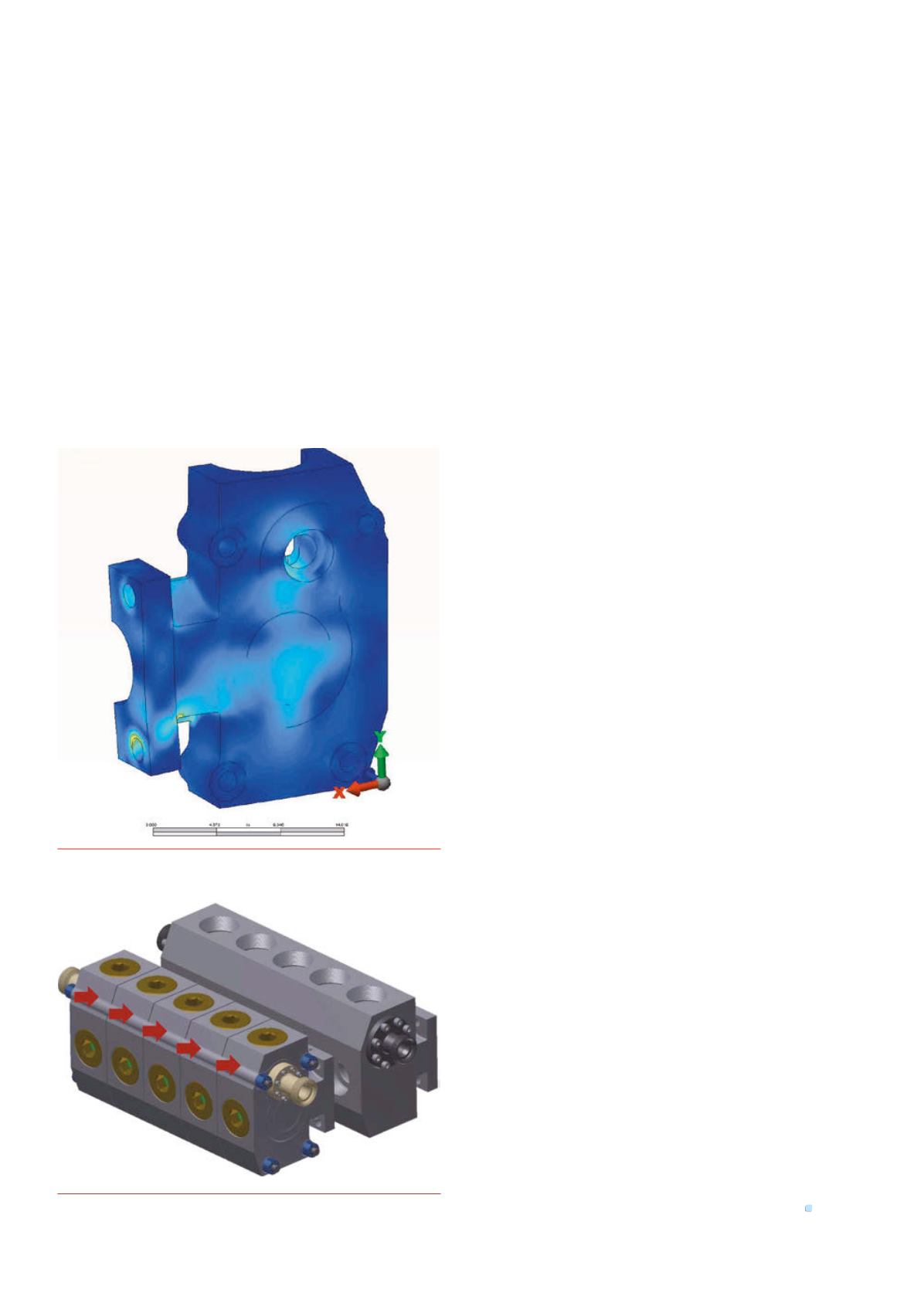

Figure 2.

FEA study conducted formodular fluid end.

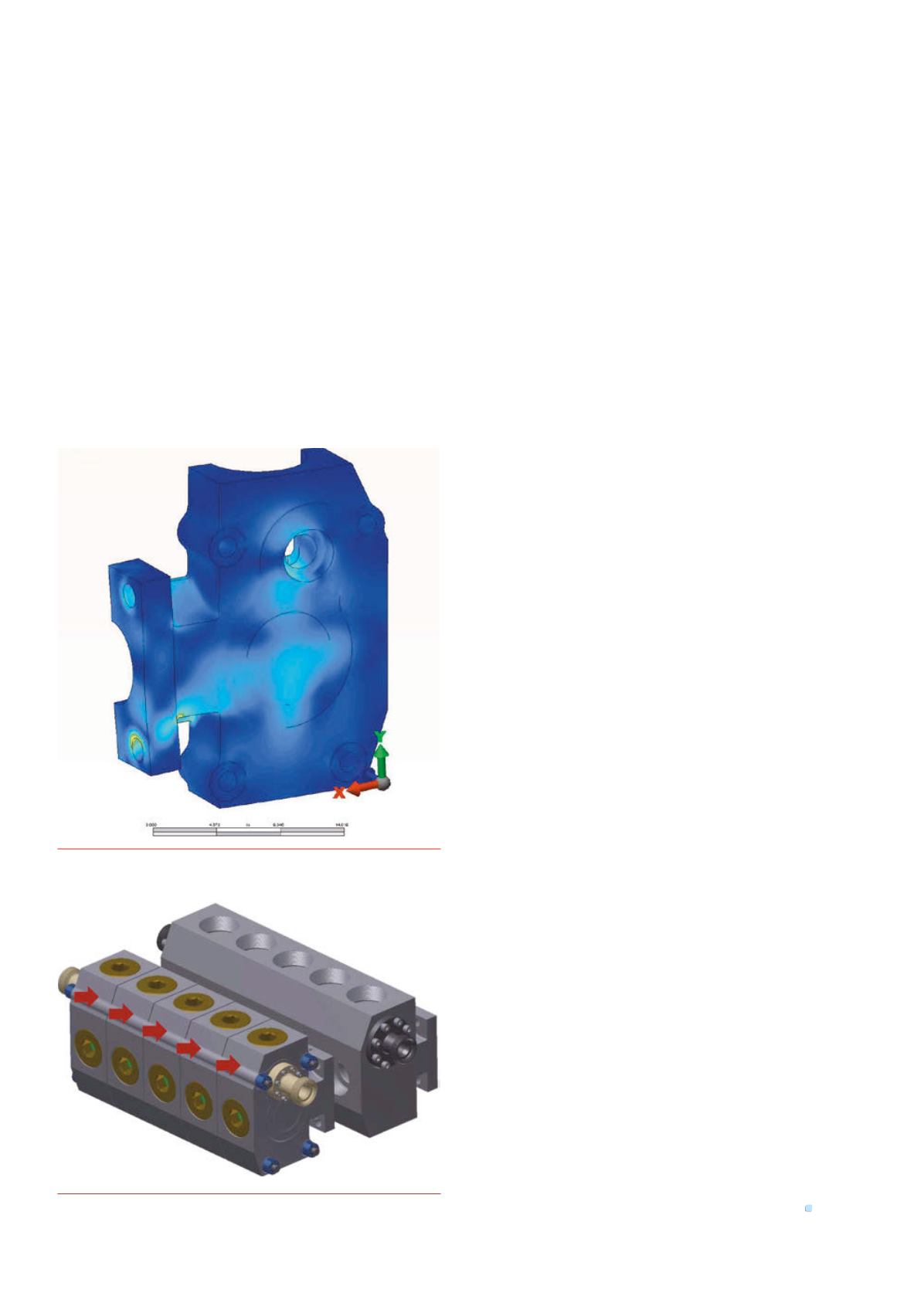

Figure 3.

Modular design compared tomonoblock design.