54 |

Oilfield Technology

December

2014

efficiently and effectively configure the stack specifically for each

situation. Sea‑bound deployment is not necessarily the optimal

method, and the time taken to break down a stack to prepare it for

air transport is valuable time wasted.

AberdeenandSingapore: strategic locations

From a deployment perspective, these locations give the best

geographical coverage of the world’s subsea fields, with easy access

to both air and sea ports for rapid response. By having the two stacks

geographically located in the northern and southern hemisphere

an enhanced level of response to the client’s well site is provided.

Having the flexibility to deploy global well control protection from

two locations mitigates any potential delays due to deployment

constraints, and adds another level of assurance to the operators’

drilling programmes.

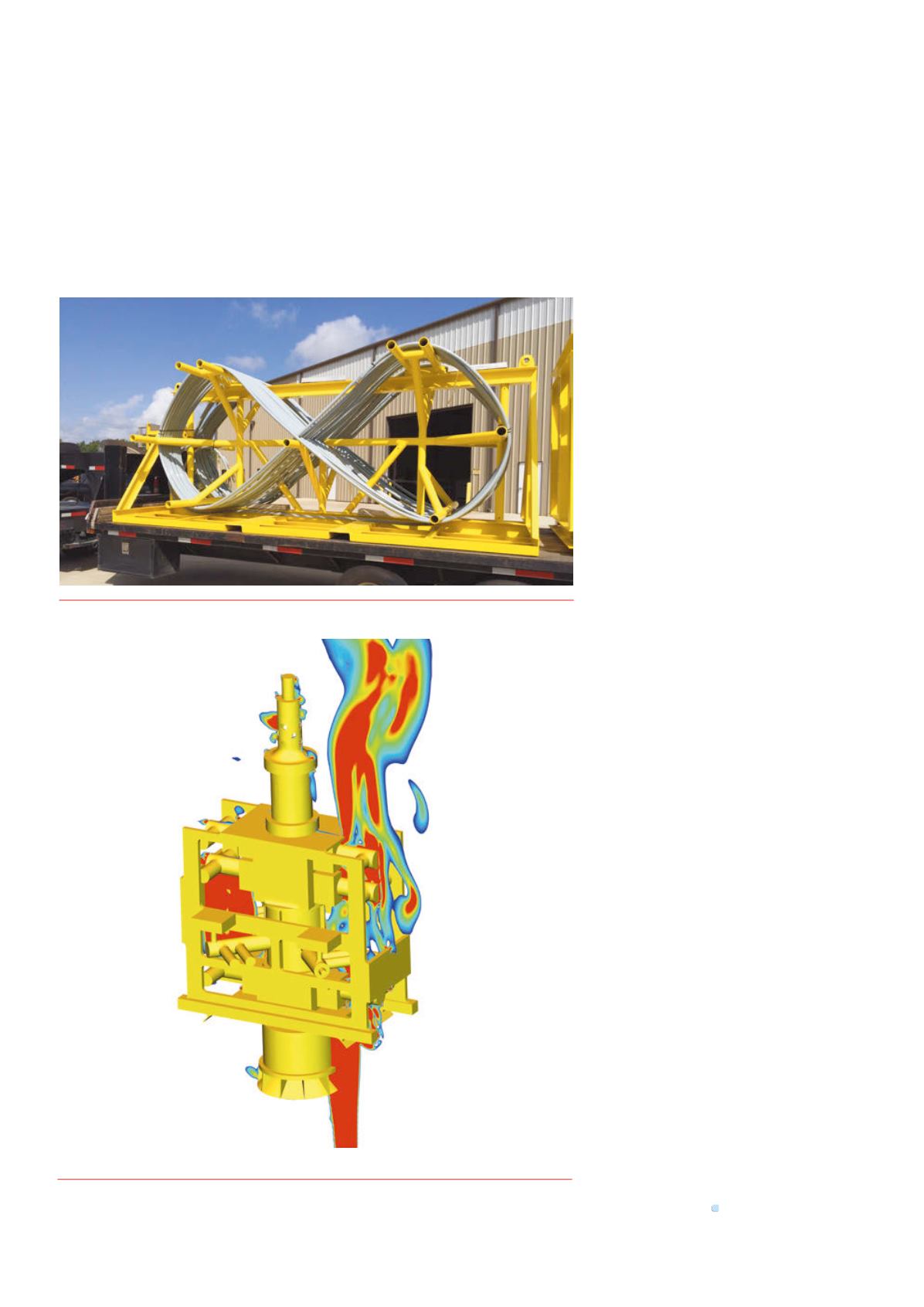

Plumemodelling

In general, plume modelling is an engineered analysis aimed at

predicting the path and destination of the hydrocarbons released

from the seabed in the event that a loss of well control results

in a subsea release. In particular, whether or not the arrival of

hydrocarbons at the sea surface will compromise efforts to bring the

well back under control by creating a flammable

or toxic hazard, or otherwise impeding efforts

to cap or kill the well. Wild Well’s Advanced

Engineering group used computational fluid

dynamics and other analytical methods to

model the subsea release from the seabed,

through the water column and beyond into the

atmosphere. However, there is always that desire

to confirm that modelling matches reality. Given

the obvious issues around physically modelling

an actual subsea release, Wild Well is part of a

joint industry project (JIP) aimed at providing

that assurance. The JIP is a combined effort to

conduct large‑scale testing and use that testing

to validate and improve the advanced computer

modelling of subsea gas releases. The first

full‑scale testing was performed in a fjord at

Høvringen, outside Trondheim in 2014 and sought

to correlate the properties of an actual plume

versus an engineering model using the same

parameters. The work continues, but indicates

that the computer‑based model replicates the

actual plume dynamics very well. Further testing

is planned, potentially on an even larger scale,

within the confines of the JIP, and space is

available for additional partners.

Conclusion

In a worst‑case scenario, equipment failure

needs to be addressed rapidly and effectively

by ‘containment’ of the subsea well. Within the

oil and gas industry, there are several subsea

well containment service providers. However,

not all of them are created equal. There are

variations in the availability of equipment (debris

removal, subsea dispersant system [SSDS] and

the capping stack), ability to handle logistics and

necessary planning, relief well/well kill, plume

modelling capabilities, well control engineering

and the experience and strength of the response

personnel team.

Wild Well works with operators and industry

agencies through drills and development of

response plans, to truly prepare for a subsea

source control event. Having access to a capping

stack is nothing without access to the planning,

logistics and well control engineers behind it. As

a company that has experience in every major

blowout, Wild Well offers a complete solution to

well control response worldwide, both before and

after the event itself.

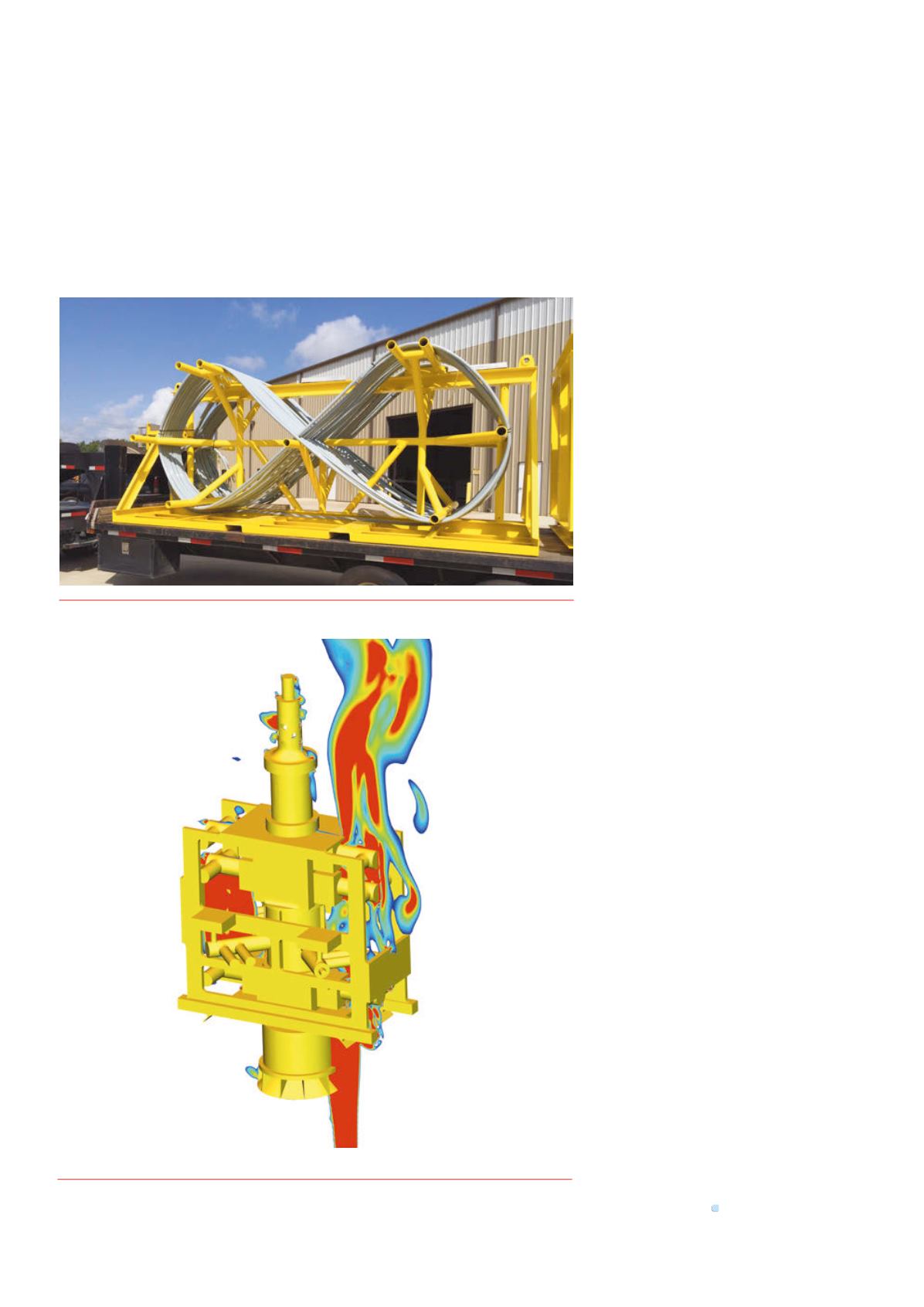

Figure 4.

Logistics planning for global locations is a vital component of the SCERP.

Figure 5.

Plumemodel of flow impact during landing of the capping stack ona subseawell

component of the SCERP.