56 |

Oilfield Technology

December

2014

International Association of Oil and Gas Producers 476 (see

sidebar) is improving the way the oil and gas industry addresses well

control training, and more drilling contractors have stepped up their

efforts by adopting competency‑assurance training to maintain their

crews’ skills during the two‑year timespan between well control

recertification.

Takethetrainingtothecrews–not thecrews tothe

training

Check‑6 has developed a portable competency‑maintenance

training system for well control that uses fighter pilot‑inspired

computer simulation and a virtual instructor: The Well Control

Competency Assurance Training System. The system eliminates

the expense of live instruction, enabling contractors and operators

to continuously maintain all their employees’ well control skills

during their regular tours – on the rig itself.

North Atlantic Drilling, the first to adopt the new system

over a year ago, has deployed the portable training system on

all eight of its rigs. This allows its crews to maintain their well

control competency through regular training vignettes during their

offshore hitches.

“We want our candidates to take their lessons during their

normal working hours offshore,” said Per Svanes, Drilling Manager

for North Atlantic Drilling. Every quarter, employees review well

control through highly realistic computer simulations. Each of the

eight lessons contains six to 10 well control scenarios that can be

addressed one at a time or all at once. An entire lesson takes each

crewmember an average of 1 ½ hours to complete. There are over

120 training vignettes that include both primary and secondary

well control scenarios.

It is important to remember that a kick does not come with a

four‑day training course in front of it. The tool is designed to train

individual knowledge, skills and understanding of well control

– regularly instead of every second year. The system has its own

independent learning management system; meaning it would not

need to connect to a company’s existing training system.

Per Svanes states that, after more than a year’s experience with

the system, the positive feedback from his users continues. “The

lessons are challenging and offer effective individual learning,”

he said.

It is worth remembering Chesley Sullenberger, the pilot who

landed his plane on the Hudson River. He had never done it

before, but he had probably practiced similar emergency landings

in a simulator. The simulator helps create close‑to‑real‑life well

control experiences. The goal is to raise levels of competence and

confidence in managing a real world situation.

After evaluating the system at North Atlantic Drilling, parent

company Seadrill has budgeted to install the Well Control

Competency Assurance Training Systems on all 64 of its rigs

worldwide.

Systemanalysis

The Well Control Competency Assurance Training System

consists of 126 training sessions that assess and document each

crewmember’s readiness and competency in kick detection and

shut‑in, as well as managing secondary well control after shut‑in.

It includes:

Ì

Simulation of both primary and secondary well control

scenarios that support individual learning objectives.

Ì

Well control crew testing and skill evaluation using

scenario‑based training with built‑in instruction and

remediation.

IOGP 476: Recommendations for

enhancement to well control training,

examination and certification

After Macondo, the International Association of

Oil and Gas Producers (IOGP) prepared new global

recommendations for well-control training. In short,

its conclusion recommends training become more

role-specific and progressive.

Furthermore, it recommends five levels of both rotary

drilling well control and well intervention pressure-control

training, using updated curricula and accredited

examinations for critical positions.

‘We can’t afford it’

The IOGP recommendations for continuing education

have not been adopted yet, but the Well Control

Competency Assurance Training System exceeds the

requirement and sets a new standard for well control

currency and maintenance. At a cost of less than

US$ 50 000/y per site, if a rig has 50 well control users,

that is less than US$ 2.75 per student per day – small in

comparison to offsite training or onsite training by a live

instructor. Plus, the system is always available to crews so

that whether they are vying for promotion, or preparing

for certification, they can continuously hone their skills

like a true professional.

Check-6 maintains the computer-based curriculum

and all the training records, with no additional burden on

clients’ IT department.

Expert analysis suggests the oil and gas industry

cannot afford not to meet these higher standards – for

now. Experience should not be measured in years – but

by the number of quality experiences that prepare people

for the unexpected.

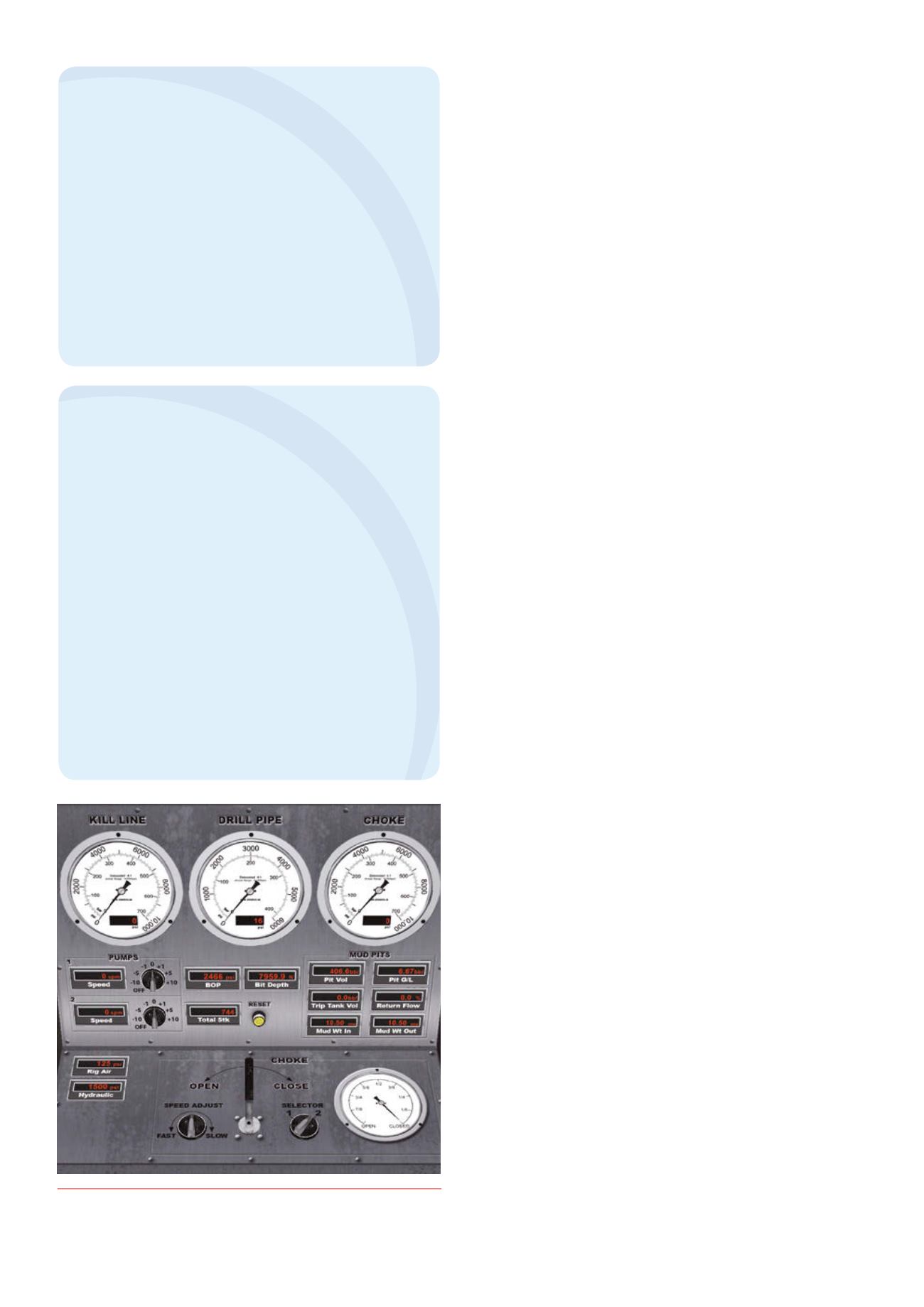

Figure 1.

Remote choke panel.