December

2014

Oilfield Technology

|

41

Common water injection systems typically have pump power

requirements of around 5 MW. The wind turbine rating should be

around 5 ‑ 6 MW and such turbines can be sourced from several

of the major manufacturers of offshore wind turbines.

Operational challenges

The subsea injection pumps inject water into the reservoir and

can be configured in a single 5 MW induction motor driving a

single pump or two 2.5 MW motors driving two smaller pumps,

which provides a backup if one fails. The pumps should ideally

inject a specific total volume of water over the lifetime of the

project to maximise oil recovery. There are pump systems

available today that would allow for the variable power

provided by a wind turbine generator.

Electrical stability

In a balanced system, the supply of electricity equals the load.

At the same time the supply or load changes, the system must

reliably seek to restore balance. It is a design and operational

challenge to achieve this. In an interconnected electricity

network, this balancing action is achieved by output power

control settings of many generators. However, in the case of

a wind turbine, the generator is responsible for the stability.

This means that the generator must ensure it meets the pump’s

power demand despite the variable character of wind energy.

Advanced control algorithms and/or energy storage are required

to assure system stability.

Systemavailability

One possible downside of the concept is that it may take

longer to undertake repairs in case of failures, compared to a

traditional water injection system on the platform. However,

increasing the level of redundancy and installing smart asset

management and maintenance procedures will improve the

system’s availability and reduce problems.

Energystorageandbalancing

Due to the variable nature of wind, there is also a small back‑up

or energy storage requirement when the turbine does not supply

power. This is to keep the auxiliary systems of the turbines

and the pump on standby to be able to start‑up operation

autonomously after a powered down period. Once the wind

starts to blow again, the turbine has to come back online so

it can restart supplying power to the pump, which is called a

black start. Two possible solutions for a floating wind turbine

unit have been identified using either a diesel backup or a Li‑ion

battery system.

Poweringahead

Though the stand‑alone wind powered system is potentially

as technically feasible and cost‑competitive to alternative

solutions, the JIP will take a more detailed approach through

analysis of a number of technical case studies to be performed

at a range of water depths of around 100 ‑ 1000 m. This will

reflect typical characteristics for today’s conventional water

injection system developments.

An in‑depth technical feasibility study will also be

undertaken where specific site and reservoir data is used. A field

currently using the conventional solution of processed seawater

injection is suggested as this would allow for more direct

comparisons in relation to technology, operational challenges

and economic viability.

Building on the results obtained from an earlier study by

DNV GL, the main critical issues to be addressed by the JIP are:

Ì

Ì

Reservoir characteristics and well system.

Ì

Ì

Floating wind turbine system design and selection of wind

turbine.

Ì

Ì

Operational challenges and pump intermittency.

Ì

Ì

System stability and availability.

Ì

Ì

Power outages and black start capability.

Ì

Ì

Economic and regulatory aspects.

Once finalised, the ambition is to use the findings from the

project to implement a guideline for wind powered subsea water

injection and to support the industry by qualifying this concept

with a prototype installation.

Acollaborative force forEOR

A successful integration of offshore wind power with offshore oil

and gas operations could provide the oil and gas industry with

a new and cost‑efficient means to develop marginal reservoirs

and enhance production in mature fields with long step‑out

distances. It could significantly reduce costs for certain activities

while also offering a new niche market for offshore wind

technology, creating momentum for both industries – a crystal

clear win-win.

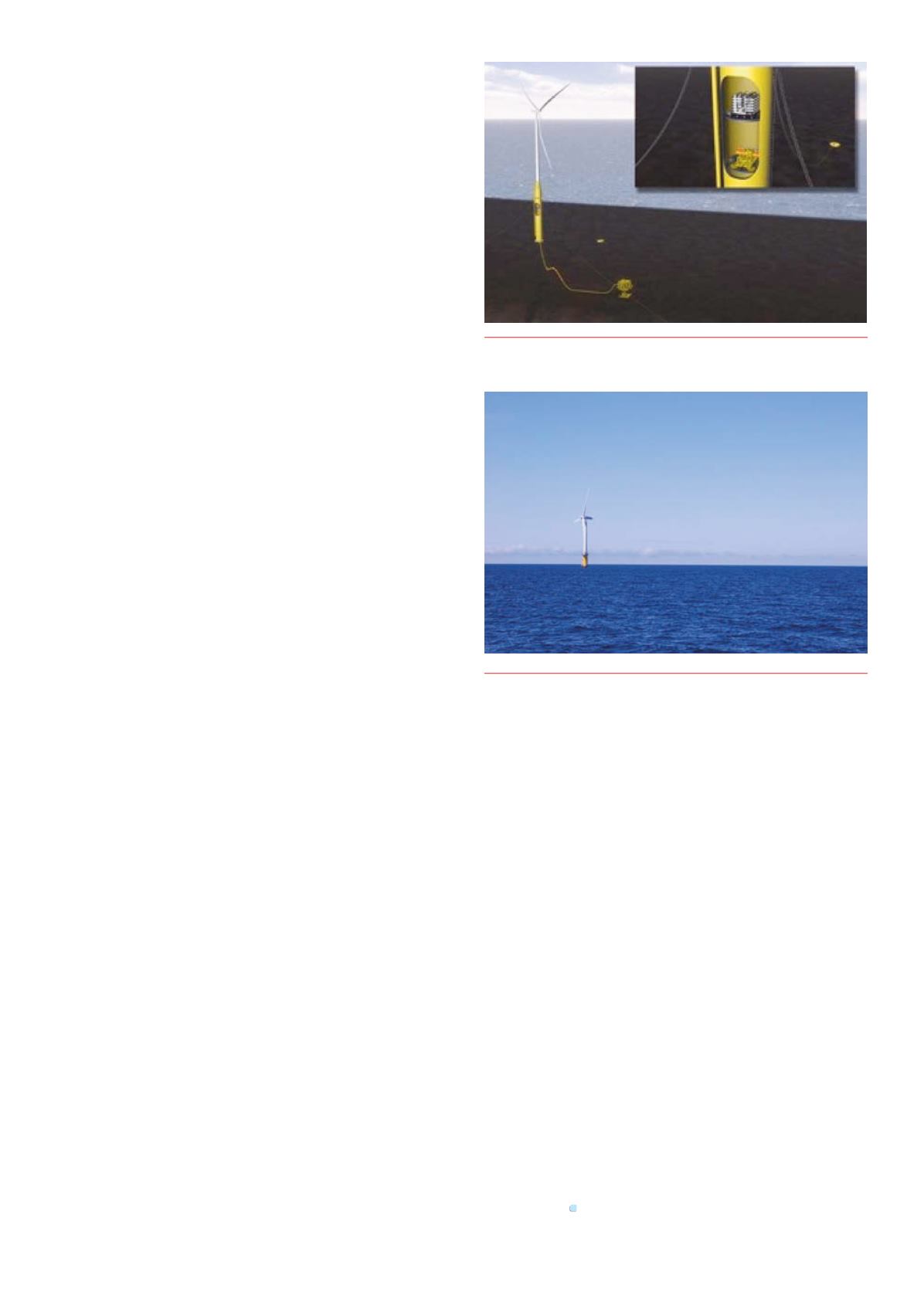

Figure 4.

Floating turbines have beendemonstrated in full

scale projects. (Image: Statoil’s Hywind turbine, photographer:

Knut Olav Ronold.)

Figure 3.

Thewind turbine sub‑structure canbe used for process

equipment suchas pumps or water treatment system.