52 |

Oilfield Technology

December

2014

What is lossofwell control?

Loss of well control can be defined in a number of ways;

uncontrolled flow of formation or other fluids, flow to an exposed

formation (an underground blowout) or at the surface (a surface

blowout), flow through a diverter, or uncontrolled flow resulting

from a failure of surface equipment or procedures. A well control

‘incident’ is defined in drilling and completion and live well

intervention as a failure of barrier(s) or failure to activate barrier(s),

resulting in an unintentional flow of formation fluid either into

the well, into another formation or to the external environment.

The causes of well control incidents are extremely varied and

complex. There are always going to be key contributing factors;

human, equipment, well conditions and meteorological. However, a

combination of factors will usually be the root cause of a well control

event and an overarching component is planning or lack of planning.

Whether it is in the design, selection, execution or human element;

all are inextricably linked and each plays a role in the end result.

What isSCERP?

Source control emergency response (SCERP) and logistics planning

should address worst‑case scenarios. First and foremost, the plan

must cover the steps needed to protect employees, customers,

vendors, visitors and those in the surrounding areas. Most operators

already have developed plans for the ‘common’ emergencies, such

as fires, oil spills, et al. However, howmany operators have taken

the extra step and considered SCERP and logistics plans. Some

beneficial steps would be to:

Ì

Ì

Train employees on what to do in a well control/source control

emergency, and hold frequent emergency drills to evaluate the

effectiveness of the well control emergency response plans. Use

these drills/exercises to let the team become familiar with the

plans and their roles in a well control emergency.

Ì

Ì

Realise that a comprehensive emergency response plan is

never truly finished. It is constantly under review and revision,

changing as the conditions of the workplace change.

At the heart of any SCERP, is the capping stack itself. On its own

and sitting at a dock or in a warehouse, it is a collection of pressure

control equipment. It requires the thoughtful, well‑planned and

repeatedly practiced support network of the operator and service

provider to activate the SCERP and put it into a position where it can

be deployed onto the event. Careful consideration must be given to

how all the components of the plan come together. Assuming that

a call can be placed in the event of an incident and that a response

will orchestrate itself, is a short‑sighted approach. The equipment,

people, plans and overall preparedness all need to be in place prior

to any emergency.

Acompletesolution

Wild Well’s WellCONTAINED solution is an integrated, complete

systemwith experienced personnel to plan and prepare, and

specialised equipment to respond to global subsea source control

events. Based on more than 39 years of conventional and subsea

well control experience, Wild Well has developed the comprehensive

solution to global deepwater well control incident prevention and

response. As previously explained, the stack is one integral part of a

whole programme of services including contingency planning and

response from SCERP through field deployment of a ‘fit for purpose’

system.

Due to the unique nature of a well control event, the equipment

is not configurable as a ‘one size fits all.’ Each event is reviewed by

the well control engineering team and the stack configuration is

developed based on all the parameters of the event. This includes,

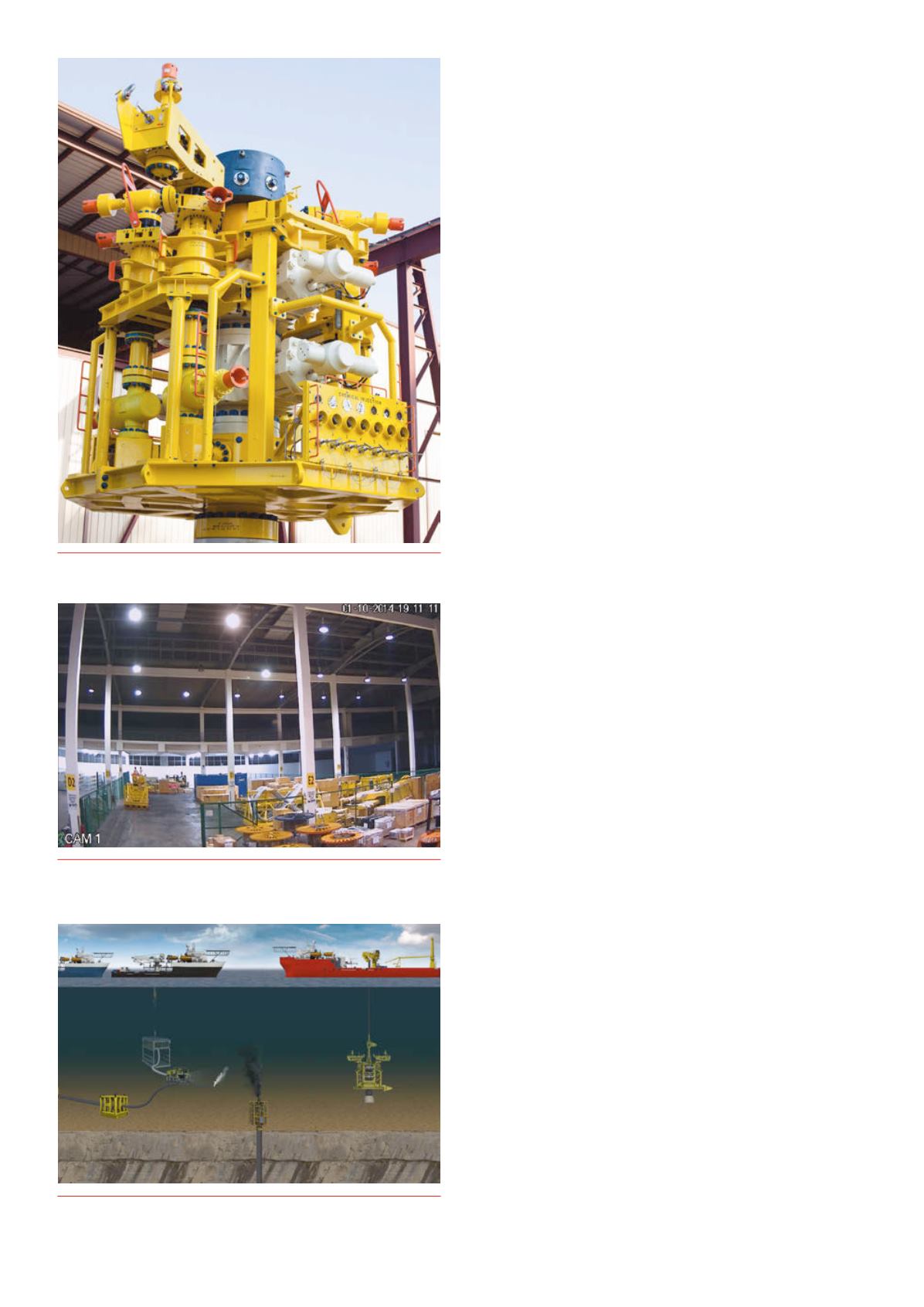

Figure 1.

TheWellCONTAINEDSystem2 capping stack is available for

response to aglobal deepwater well control incident.

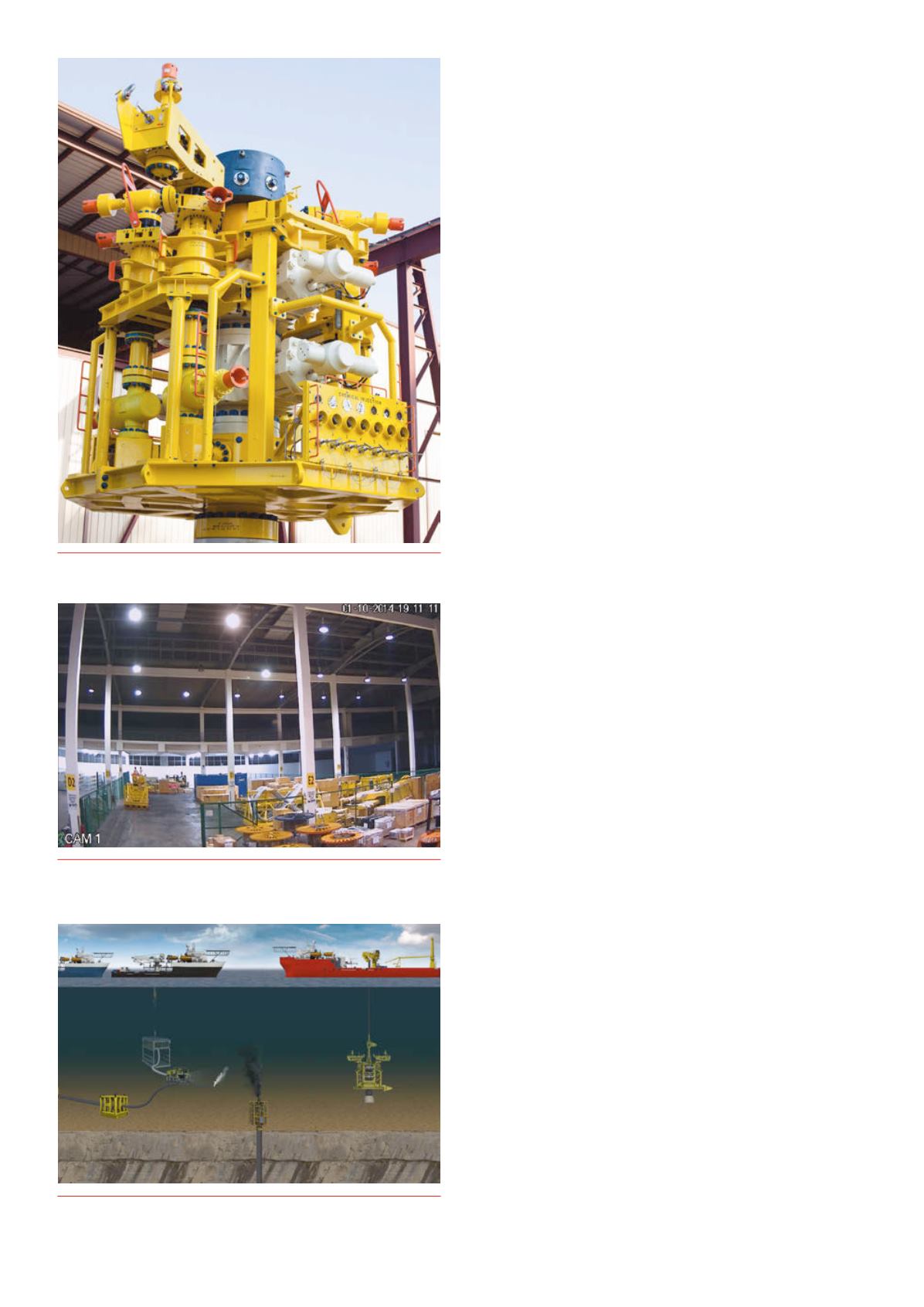

Figure 2.

All components of WellCONTAINEDSystem2 are staged in

a secure area of the Singapore facility ina state of readiness for rapid

deployment.

Figure 3.

SIMOPanimation usedduring training exercises anddrills.