40 |

Oilfield Technology

December

2014

platform, provide access to systems normally located subsea,

increase the flexibility of injection location and reduce the

installation time. It would also be possible to move the system

and use it at new locations after the closure of a well or field.

New challenges will also arise but these should be possible to

overcome with manageable efforts.

Driving innovationthroughcollaboration

Now DNV GL is launching a collaborative industry project

(JIP) ‘WIN WIN – WINd powered Water INjection’ to assess the

technical and economic feasibility of using floating offshore

wind turbines for powering subsea water injection systems for

enhanced oil recovery (EOR).

A number of operators, engineering companies, research

institutions, authorities, offshore wind technology developers

and turbine manufacturers have already shown interest in the

project and more participants are welcome to take part.

Limitationsof traditional systems foroffshore

water injection

The upstream industry has for many decades injected water

into oil reservoirs to increase recovery. Many of the systems are

technically complex, energy‑intensive and space consuming.

Traditional solutions using fully processed injection water

are affected by the necessity for long power cables and water

injection flowlines, which are major cost drivers.

Not only is procurement and installation expensive, the

systems are prone to damage that can result in the potential

loss of production and need for expensive repair. With longer

distances to transport the processed injection water, the power

requirement also increases.

Otheralternatives

Injection of raw seawater, if reservoir characteristics allow

for it, offers a solution for water flooding that minimises the

water injection flowline. This solution has been successfully

implemented on the Norwegian Continental Shelf and

internationally. The Tyrihans field in the Norwegian Sea is one

example where the injection water is not pumped from the

platform, but withdrawn directly from the sea by a seawater

injection subsea unit, powered and remotely operated from the

Kristin platform 31 km away.

However, similar to the traditional method, the raw seawater

injection is normally powered with gas turbines on the host

platform and long power cables may be required.

Windpower

The WIN WIN concept is based around a floating wind turbine

system that is essentially separated, and at a distance from

the production platform. The power for the water treatment

systems, injection pumps and the auxiliary systems will be

supplied by the wind turbine generator itself. This power can

be combined with a variety of water injection technologies,

ranging from raw seawater injection as the simplest to

LowSal water injection (low salinity water from a reverse

osmosis process) as the most complex.

While wind is not suitable for most oil and gas applications

due to its intermittency, the water injection process is less

sensitive as long as a specific volume of water is injected over a

given time period. This would typically be in the range of days

or weeks, so the water need not be delivered at a constant rate,

which means the system can function with a variable source of

power like a wind.

Economic feasibility

The WIN WIN concept brings advantages which can justify the

investment in given cases. The flexibility with respect to location

means that the water injection system can be placed at optimal

locations far from the production host without worrying about

costly power cables or water flowlines. The stand‑alone system

does not occupy space and power from the production host, and

can in some cases save the need for costly modifications and

free space and power for other functions. In addition, the system

reduces gas consumption and associated gas and emission

costs.

The economic rationale of the concept is heavily dependent

on the characteristics of the field. The best business cases are

typically applications with marginal fields where associated

gas for fuel is limited and tie‑back to other production hosts or

import of LNG or diesel are the only main alternatives. Another

strong rationale can be found in situations where production

hosts do not have power generation capacity to support an

increased demand for water injection.

Technical considerations

Any of the three main floating wind turbine structure designs

(spar‑buoy, semi‑submersible and tension leg platform) are

deemed to be feasible for this application, although some

modifications would be required to prepare for possible storage

systems, additional tank space and control systems.

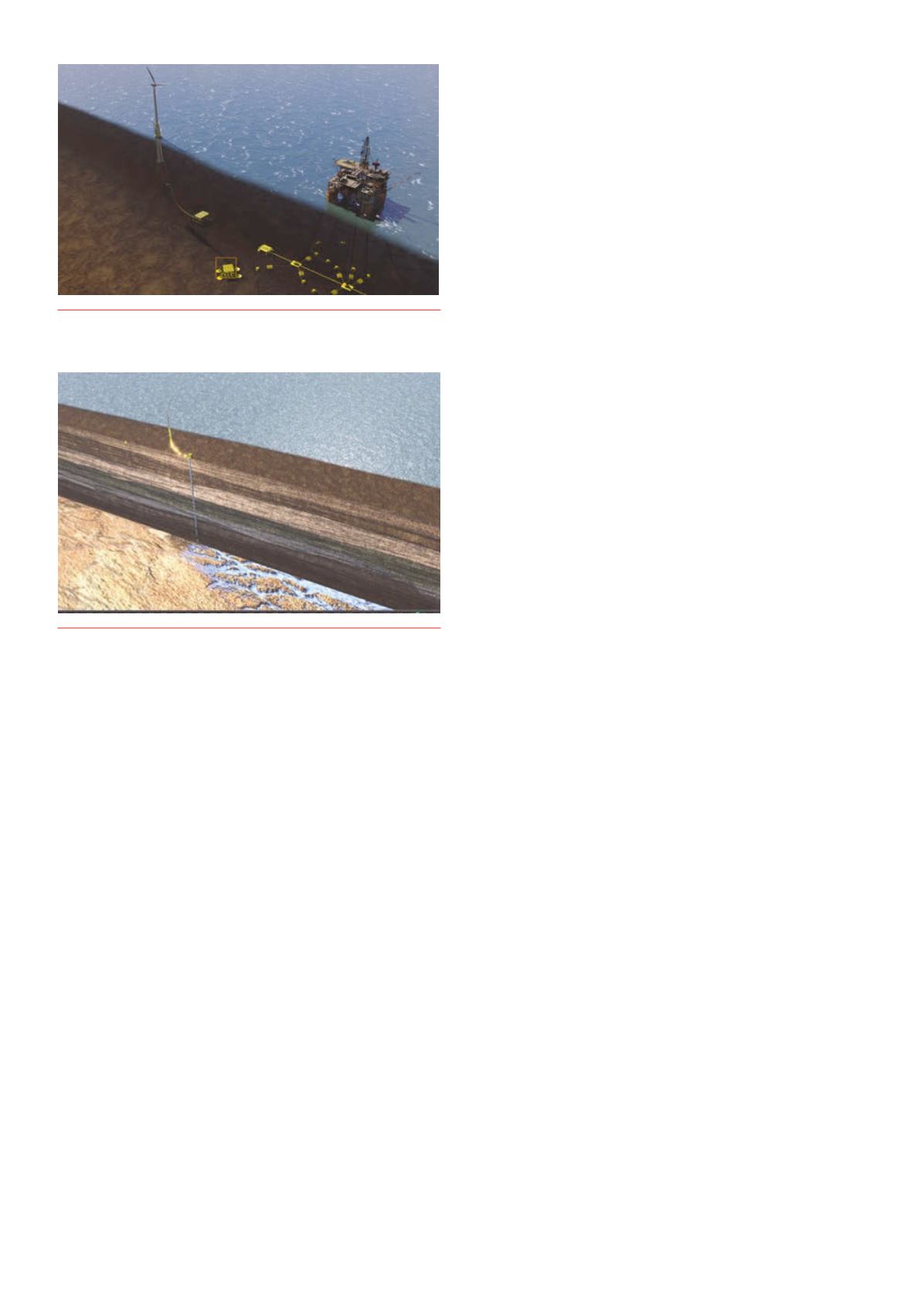

Figure 1.

The stand‑alone system is physically disconnected fromthe

productionplatformand fully controlledby the operator.

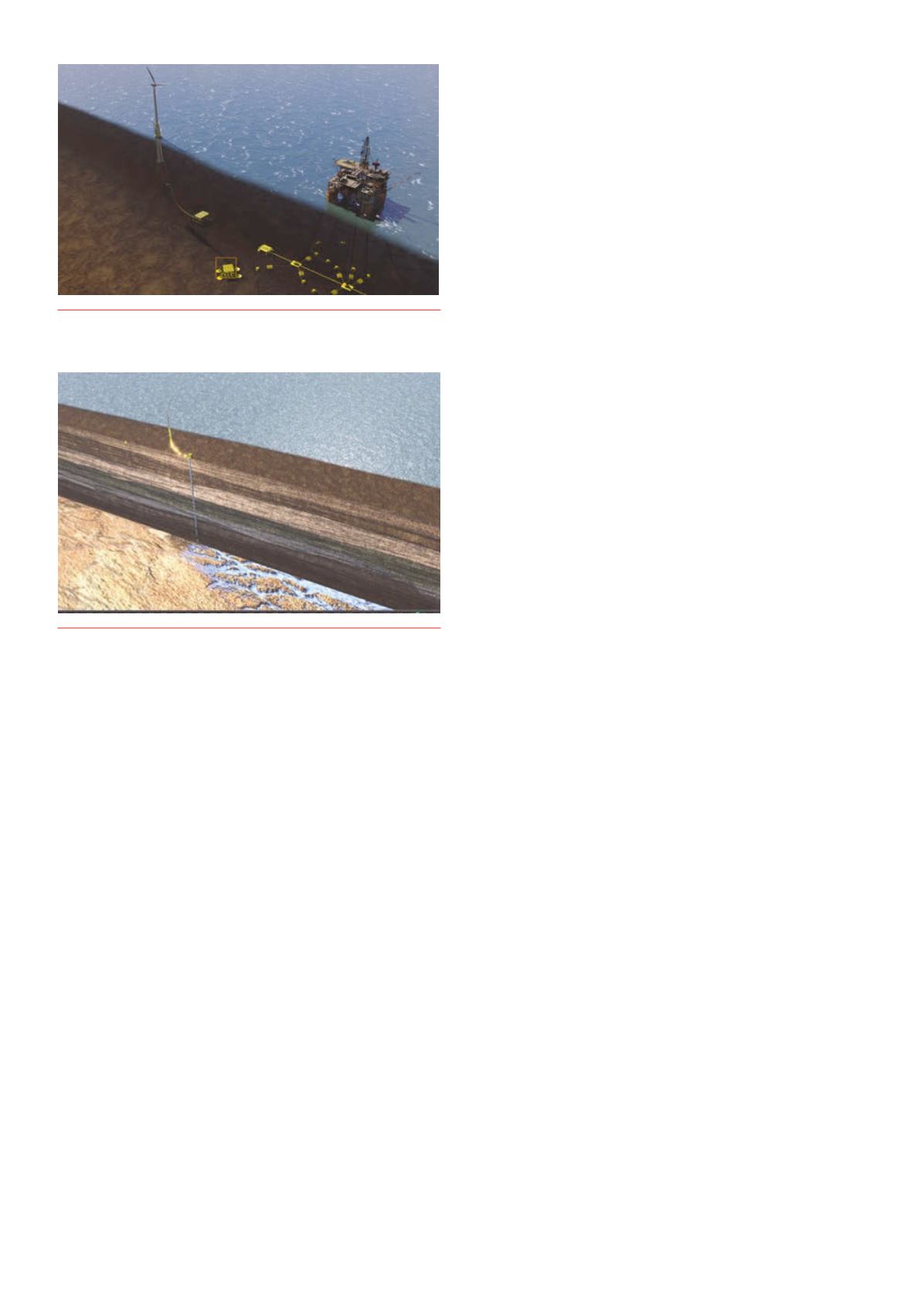

Figure 2.

Having the power source close to thewater injectionwell gives

great flexibility and lower costs.