deterioration are normally managed well if robust asset

management systems are in place. The area that is

generally not so well covered is where changes arise from

increased knowledge or learning. This is the case in

learning from incidents, be that within a facility or on a

global level, or where the industry’s knowledge of a

particular topic moves on.

New risks are also introduced before production start

up, when either the actions from the original HAZOP are

not adequately completed or when the design is altered

after the HAZOP and the changes not controlled. These

risks should be controlled by robust project management

processes, procedures and controls.

The risks arising from omissions occur because the

original study team ‘missed’ something; failed to identify

a hazardous scenario, underestimated the potential

consequences, underestimated the likelihood of

occurrence etc. Trying to minimise omissions is clearly

important and relies on a number of factors including; the

experience and rigorous approach of the leader, the

knowledge of the team, the time allowed for the

HAZOPs, the level of independence of the HAZOP leader

from the project manager, the availability of specialist

input and vendor knowledge, the pressure (directly

expressed or implied) on the team to complete studies

quickly, the operational experience accumulated in the

process being reviewed, the methodology used and the

state of the design.

This discussion illustrates the great difficulty in

getting a comprehensive risk assessment for a new

project and the even greater difficulty in maintaining the

risk assessment. Even with excellent and robust

management systems for MOC projects, asset

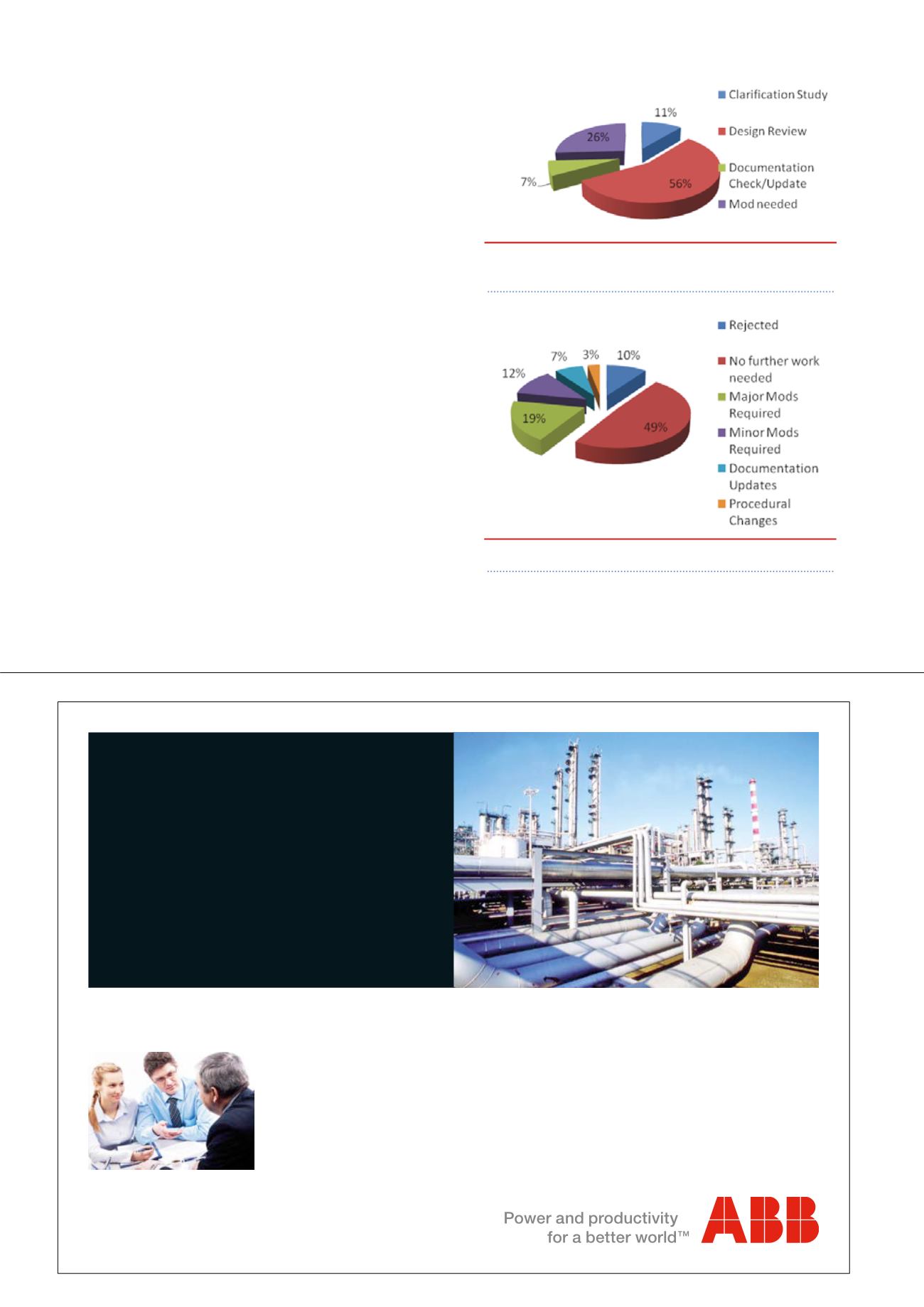

Figure 2.

Typical classification of actual outcome.

Figure 1.

Typical classification of outcome

expected by HAZOP team.

Oil and Gas operators aiming to achieve operational excellence in the face of

ageing assets, harder to reach reserves, cost pressures and skills shortages,

often require expert assistance. ABB Consulting offer the oil and gas industry

expertise in: inspection, integrity management, operations improvement,

process safety, project services, site and asset closure, technical engineering,

technical software, technical training and competency. We benefit customers

by reducing risk, optimising cost and improving manufacturing efficiency.

ABB Consulting.

Safe, reliable, efficient

operations.

ABB Consulting

Tel: +44 (0)1925 741111

email:

Hydrocarbon Engineering (180x130) Nov 2014.indd 1

11/11/2014 11:09:30