PUMP

&

TURBOMACHINERY

equipment review

SEPTEMBER

2014

67

limited panel space and its low power consumption significantly

reduces control system life cycle cost and makes it a perfect

solution for a floating LNG (FLNG) plant.

PRODIGY allows for seamless legacy systemmigration by

using proven control algorithms for risk mitigation; migration is

even possible during a planned shutdown.

This technology offers total application control to help

maximise productivity and profitability, while reducing risk

throughout each cycle. The PRODIGY platform is a revolutionary

control solution for any LNG industry application around the

globe.

Cryostar

T

aking advantage of the 40-year experience of the company

in cryogenic pumps for industrial gas applications, Cryostar’s

new pump development MX uses the best features of globally

renowned VP and MCP ranges. With a record of more than 500

of these existing pumps delivered in 2013, a new technical and

commercial success is expected from the MX pump type.

Designed for continuous duty process applications focused

especially, but not exclusively, on air separation units and

liquefiers, the MX pump range is available in 2 or 3-stage

configuration and 2 wheel sizes (220 and 260mm) to reach flows

up to 1500L/min and design pressure of 50 or 60 barg depending

on execution.

Dresser-Rand

D

resser-Rand is among the largest suppliers of

custom-engineered rotating equipment solutions for

long-life, critical applications in the oil, gas, petrochemical,

power generation, and process industries. The company has

been involved with the world’s leading LNG producers since the

technology was first introduced.

Dresser-Rand’s latest innovation for the LNGmarket is its

LN

Go

systemwhich uses a combination of Dresser-Rand

technologies, including its MOS™ reciprocating compressor, its

Guascor

®

gas engine and Enginuity

®

control system in a portable,

small-footprint package that can be placed on well pads, gas

flares and similar sites.

The system allows for very small stand-alone plants that are

portable and can be moved to support changing requirements

and needs. The LN

Go

System is sized to produce approximately

6000 gal./d of LNG and can be used in upstream, midstream and

downstream applications.

In addition to LN

Go

technology, innovations in the

Dresser-Rand high-efficiency DATUM

®

line of centrifugal

compressors have supported significant advancements in natural

gas recovery and transport. Dresser-Rand innovations in

compression technology, rotor dynamics, head capacity, and

efficiency per compression section provide incremental

production gains. Other innovations in compressors for LNG

applications can help maximise production by reducing the

number and duration of maintenance shutdowns.

Ebara Cryodynamics

E

bara Cryodynamics is a leading manufacturer of cryogenic

pumps and expanders for the many segments and

applications of the worldwide liquefied gas industry. With

over 40 years of continuous engineering advancement, Ebara

Cryodynamics’ machines incorporate the highest calibre

of engineering and technological advancement, delivering

dependable and efficient equipment.

Ebara Cryodynamics’ equipment reaches across traditional

applications into expanding markets, including fixed and mobile

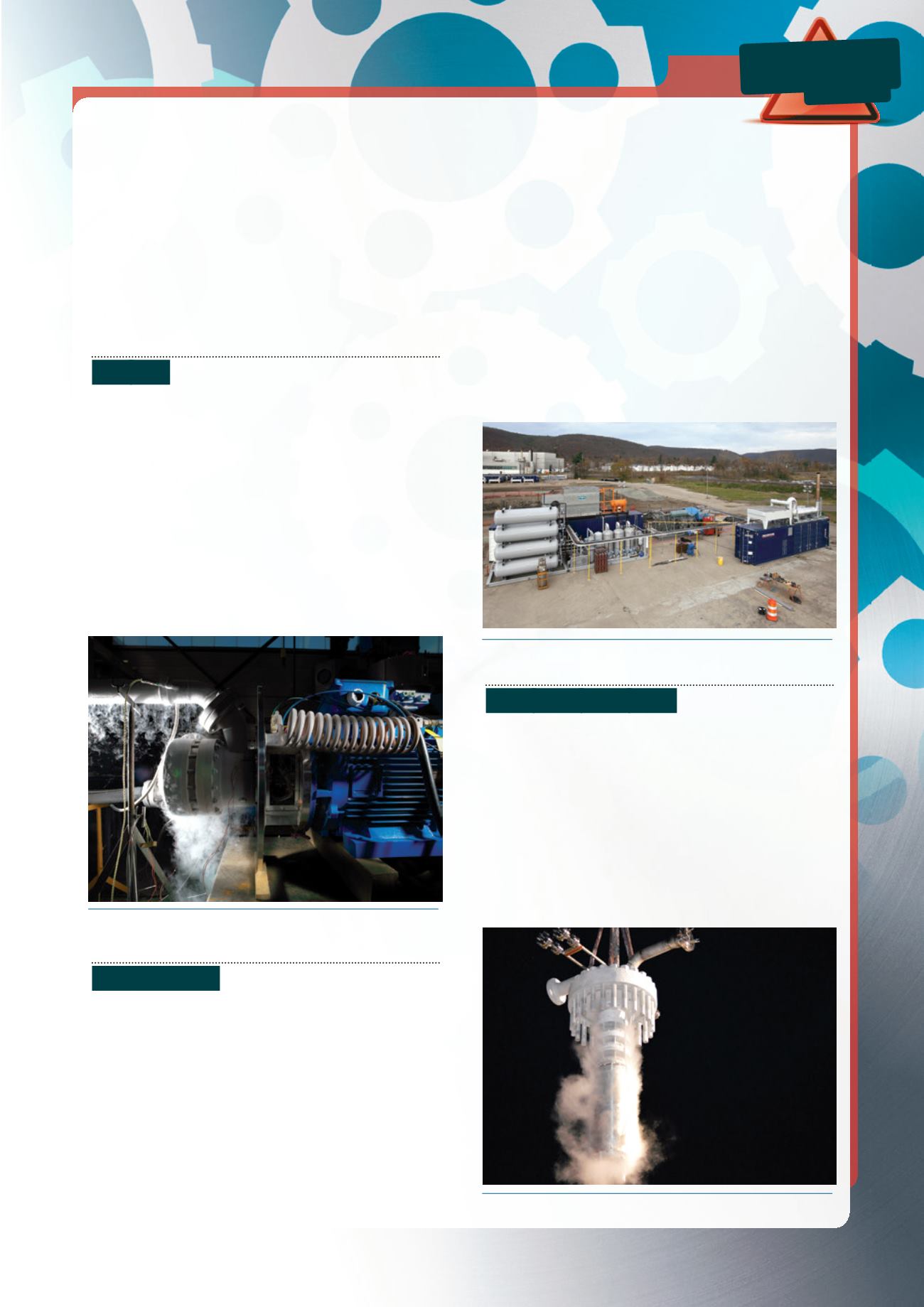

Cryostar’s MX pump

©

.

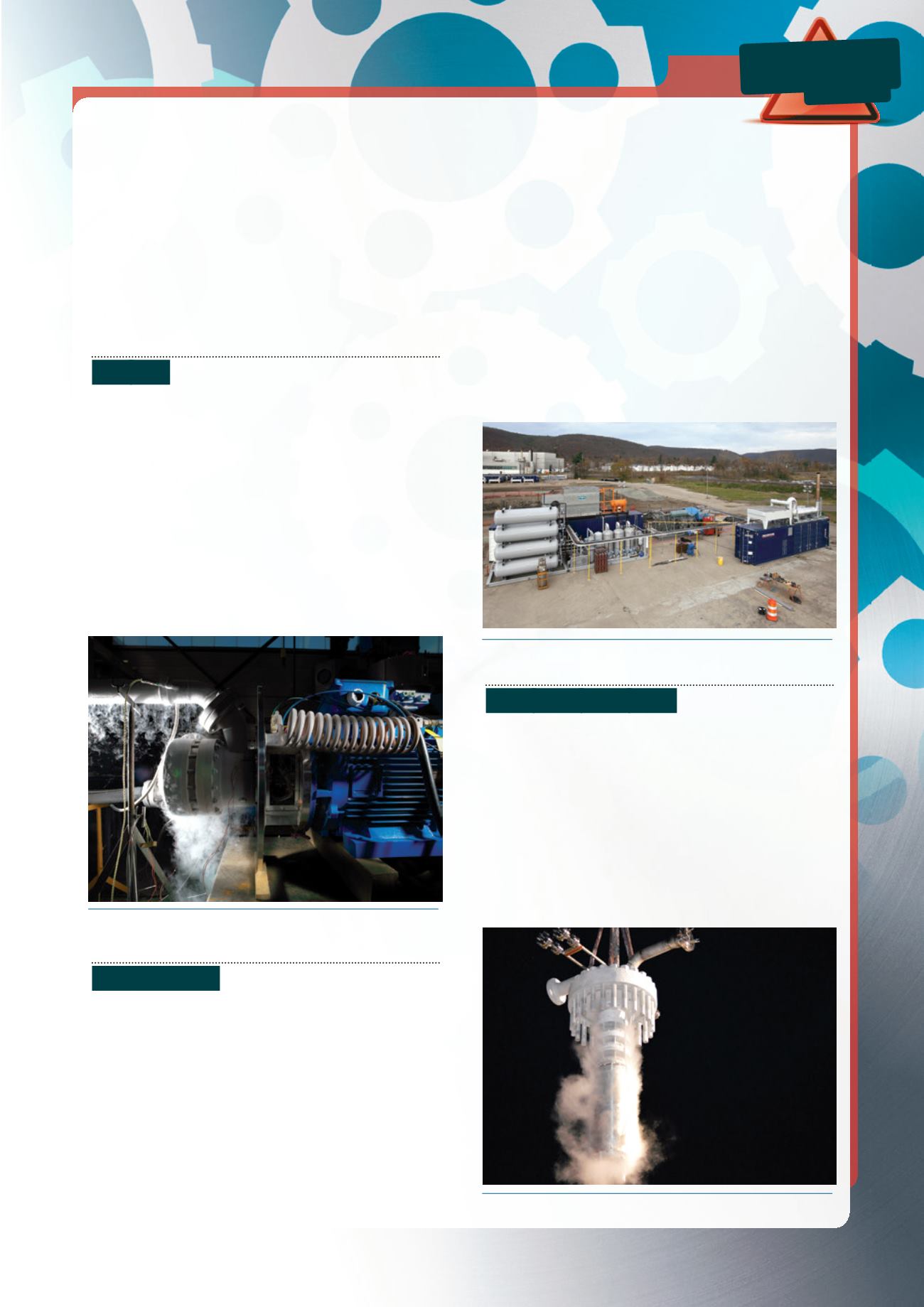

Dresser-Rand’s LN

Go

System.

Ebara International’s MR Expander post FAT testing.