62

LNG

INDUSTRY

SEPTEMBER

2014

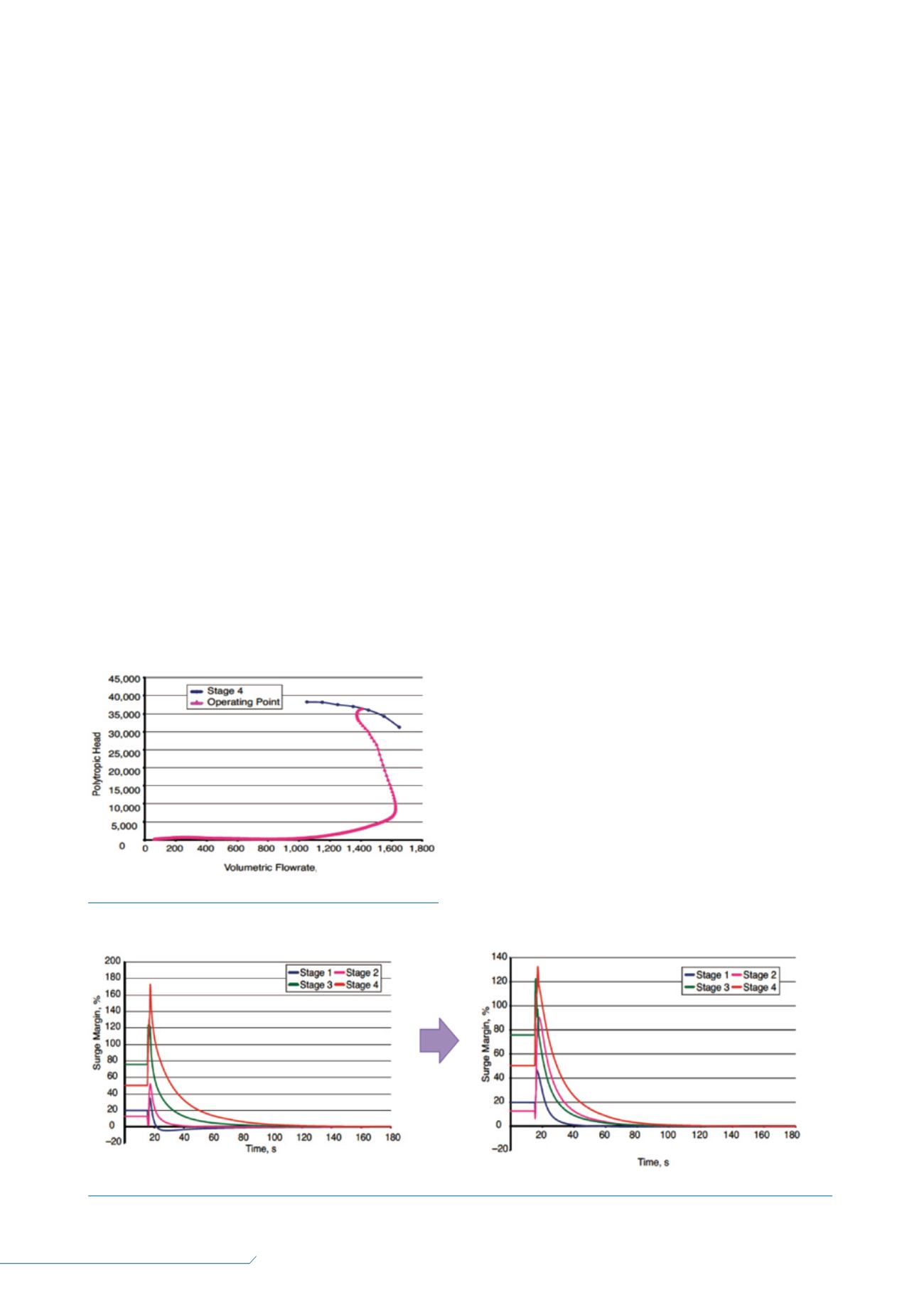

showed that adding a hot-gas bypass around the first two stages

of compression would enable the compressor to move out of

surge (see Figure 2).

Imagine the cost of researching and solving compressor surge

issues on a machine in real time: every time a compressor moves

into surge, the risks of equipment damage are significant. Using

simulation, this plant was able to perform research and add a

hot-gas bypass in early design stages when changes could be

made with minimum cost and risk.

Dynamic simulation also helped reduce power consumption

costs and improve efficiency by allowing engineers to test

compressor size and selection against actual process requirements.

This ensured optimum recycle flow rate under normal operating

conditions. In pre-FAT stages, running the actual control code

integrated with a dynamic simulation model made it easier and

less expensive to debug and improve control programmes.

Save time

After looking at even one instance of dynamic simulation in

action, it is easy to see how it saves time. For example, in a factory

acceptance test (FAT), the integration of dynamic simulation and

turbomachinery control programmes allows for detailed testing

of the actual control programme logic and sequencing. Having

a relatively clean and tested control code ready before the FAT

saves critical time during the test. During site acceptance testing

(SAT), changes to the control programme can be tested against

the model and corrections can be made prior to going live on a real

system, thereby saving time on commissioning.

Traditionally, tuning of proportional-integral-derivative (PID)

controllers is performed in the plant after start-up. However, at that

point, any undesirable response could cause compressor surge and

risk the safety of operators and machinery. With dynamic

simulation, tuning of PID controllers and step changes is performed

in the virtual plant before commissioning. Tests are performed in a

risk-free environment and generally only fine-tuning is required

after start-up.

In an olefins plant in the US, dynamic simulation was used to

evaluate the best control strategy for the four-stage steam turbine

driven ethane recycle compressor. Simulation allowed the plant

engineers to determine the value of decoupling between the

kickback valve and the inlet guide vanes (IGV). Because the plant

was able to test surge control and speed control responses via

simulation, the compressor start-up went smoothly and

commissioning was reduced by three days.

Improve safety

Evidence shows that implementing a tested, well-designed and

well-tuned controller can dramatically reduce the potential for

unsafe scenarios. However, one of the key ways that simulation

enhances plant safety is in its ability to train operators. In a

workplace where small mistakes can have heavy consequences, it

is imperative for operators to respond correctly and immediately.

The value of simulation can be seen in many fields where there is

next to no room for error, e.g. in space flight, astronauts undergo

rigorous virtual training so that their real-time execution will be

flawless because they have worked through all possible scenarios

in simulators.

In the US olefins plant, the same dynamic simulation models

that facilitate design and implementation phases will continue to

pay off in operator training. An integrated turbomachinery dynamic

simulation model can be used to conduct operator training

throughout the whole process, before, during and after start-up.

Experiencing simulated malfunctions and results prepares

operators to make safer decisions with actual equipment.

In a report entitled ‘Why we need a better approach to

procedural automation’, Larry O’Brien claims that training can

reduce the time it takes for an operator to progress in competency

by 30 - 50%.

1

Using simulation, operators prepare for emergencies

under real-world conditions, learning how to avoid upsets and

shutdowns. O’Brien estimates that operational error contributes to

over US$ 80million in loss per accident. His research shows that it

causes greater expense than natural hazards, process upsets,

mechanical failure, and sabotage/arson. The other loss factor he

cites is design error, which can also be improved early on via

dynamic simulation.

Figure 2.

Hot-gas bypass solution. Note: a negative surge margin (above) indicates that the compressor is in surge.

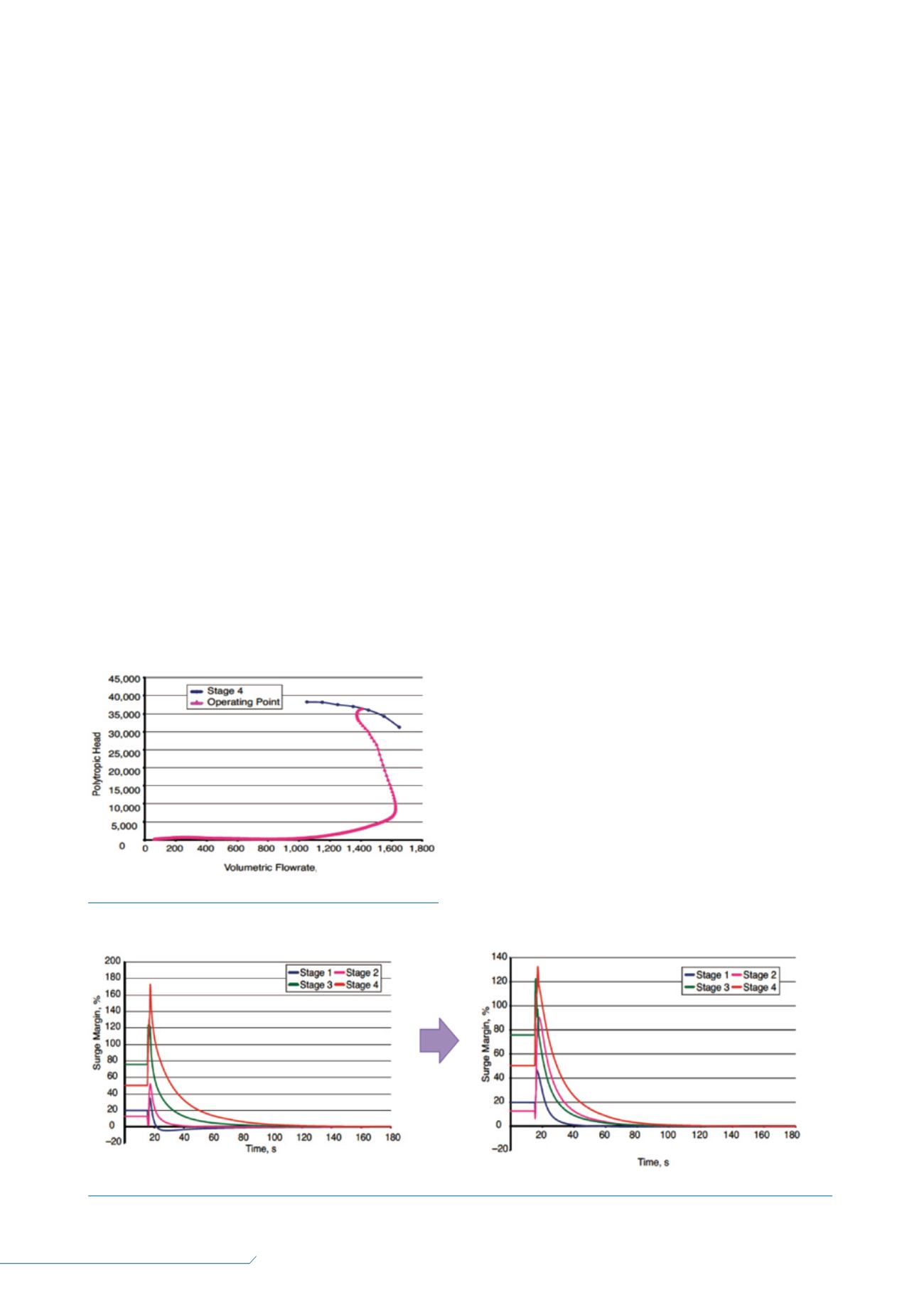

Figure 1.

Equipment sizing and selection.