20

LNG

INDUSTRY

SEPTEMBER

2014

Samsung C&T was awarded the contract to build an

additional 180 000 m

3

LNG tank at the terminal. In July 2011,

the company was again selected – this time to build the

terminal’s secondary berth and enhanced works order to

expand its facilities to increase its send-out capacity from

3.5 million tpy to 6 million tpy.

The project’s requirements necessitated engineering,

procurement, multi-discipline (mechanical, piping,

electrical) construction and other works to be performed

simultaneously. Therefore, it required an EPC firm with

sufficient expertise and experience in the related field.

Samsung C&T is experienced in building LNG terminals and

tanks in South Korea. The company combined the advanced

cryogenic tank construction expertise it had gained through

these projects with advanced planning, simulation, and

precision process management techniques to complete the

Singapore LNG terminal project on time and within budget.

The single most important process in building an LNG

terminal is the construction of tanks for storing LNG in a

cryogenic state. These tanks consist of an inner wall and an

outer wall. The outer wall is made up of 75 cm thick

reinforced concrete. The wall was constructed by using

‘jump forming’, requiring a total of 10 ‘lifts’ of the formwork

followed by 10 concrete pours. One of the most important

processes in building the outer wall is the installation of the

tank roof.

For the Singapore LNG terminal project, Samsung C&T

chose to apply a technique known as air-raising, which

involves fabricating the top inside the tank and raising the

1060 t structure to the top of the tank by introducing air into

the internals of the tank. The company first sealed all the

space between the roof and the side walls of the tank and

introduced air at a pressure of around 205 mmAq using a

blower. It then pushed the roof from the bottom to the top,

a process that took 3 hours, moving 200 mm per minute.

Another key factor when raising the roof was that it should

remain horizontal during the entire process. Thus, during

construction the company installed a weight to maintain

balance and set up a levelling wire system in approximately

30 places in order to maintain the right level.

The inner walls of the tanks were made using a special

alloy that can withstand cryogenic temperatures down to

-196°C. The alloy is 9% nickel steel, and Samsung C&T

utilised its quality management and schedule management

expertise to prevent the material from coming into contact

with moisture, magnets, and other metals throughout the

entire construction process. Stiffeners were also utilised

when installing the inner plates to prevent them from

warping and to minimise the amount of welding required,

enabling faster completion. The opening, used as the

access point for materials and manpower, was located in

the first ‘lift’ of the outer wall. Conventionally located in the

second ‘lift’, this change further enhanced the construction

efficiency and safety.

Samsung C&T commissioned the third tank and the

secondary berth independently. The company

systematically managed tasks and document handover to

Singapore LNG Corp. (SLNG), the owner of the project, for

each commissioning system using a programme developed

by the project staff.

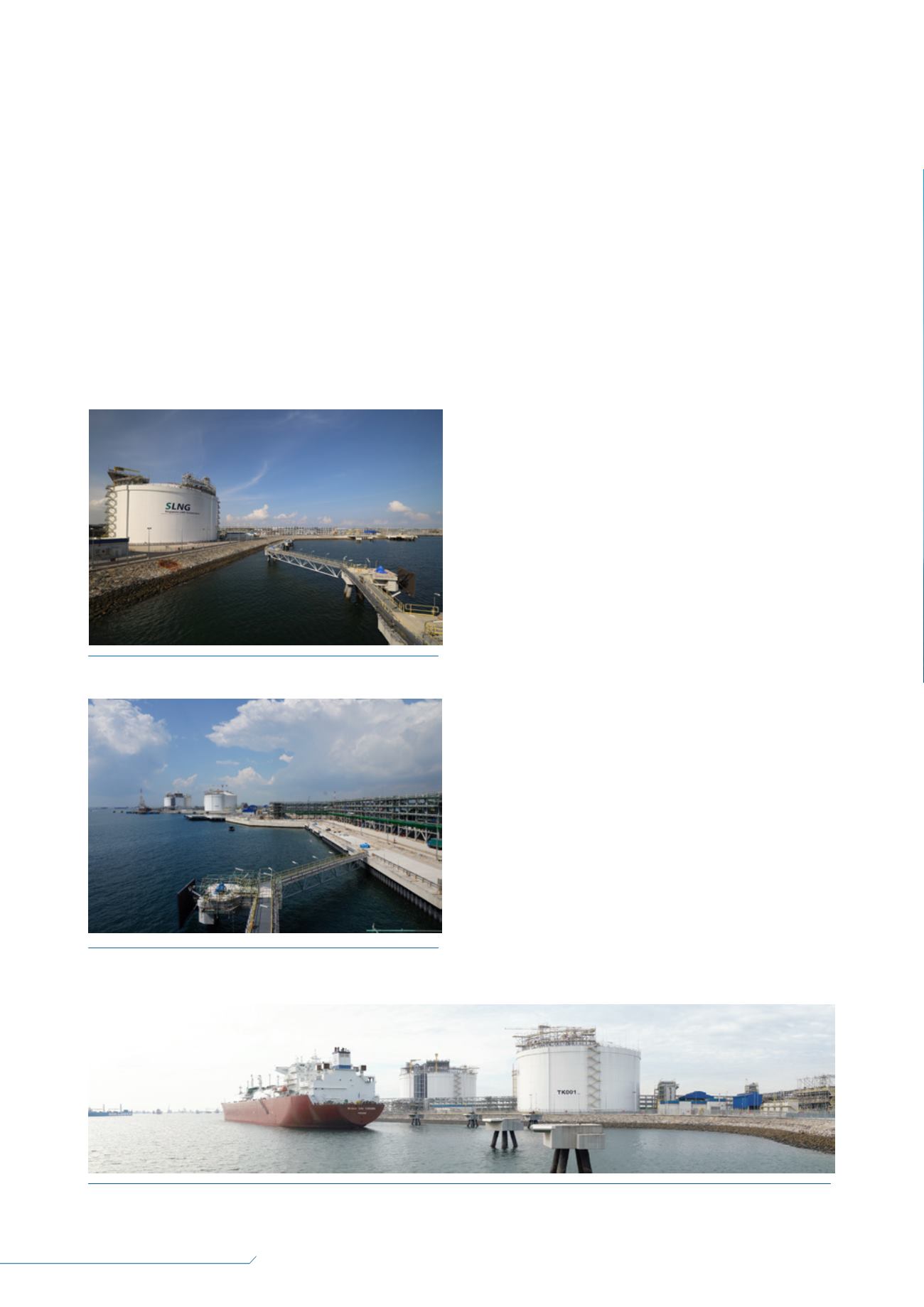

Figure 1.

Overall view of the terminal (from the primary jetty).

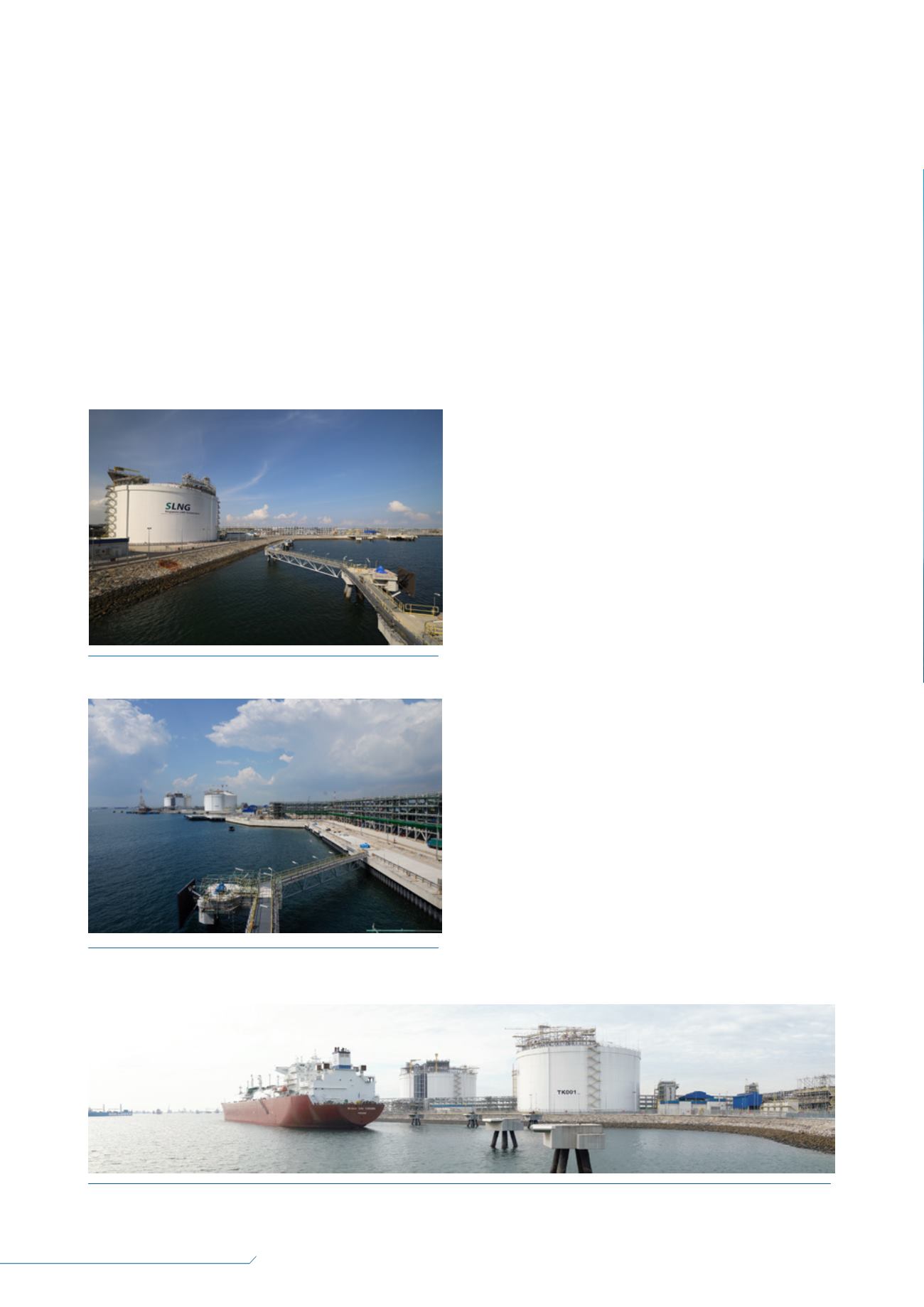

Figure 2.

View of the terminal (from the secondary jetty).

Figure 3.

Panoramic view of the terminal (from the tertiary jetty).