review

102

PIPELINE

MACHINERY

Sawyer MFG, USA

For many years the Sawyer brand

has been synonymous with pipeline

product development, and 2014 is

proving to be no exception. A new range

of clamps, both standard and ultra, is

being developed to take on some of the

toughest reforming jobs in the industry. The

Rim Clamp and Ultra Rim Clamp are being

introduced into Sawyer’s superior range of

pipeline and welding equipment. The Rim

Clamp series provides a viable alternative

to the Double Chain Clamp for customers

who prefer a clamp with a rigid shell.

Both Sawyer Rim Clamps are designed

for use on out-of-round pipes which require

a high level of accuracy in their alignment.

Each clamp is available in a range of sizes to

accommodate pipe sizes from 4 - 72 in.

The Rim Clamp is ideal for tough

reforming jobs and is capable of reforming

X45 Schedule 80 pipe with out-of-round

conditions up to 2 in. Pressure is applied by

heavy duty jackscrews to precisely reform

the pipe. This rigid clamp is extremely

accurate and provides precise alignment

capabilities.

The Ultra Rim Clamp is a heftier clamp,

built to reform high tensile strength

pipe with out-of-round conditions up

to 2.25 in. Modern materials allow this

clamp to be lighter and stronger than its

predecessors. The component parts of the

clamp have been improved to provide

a better finish and accuracy. Proper

pre-treatment and powder coat finish on the clamp results

in corrosion resistance. The Ultra Rim Clamp offers more

extreme reclaiming capability, readily reforming high tensile

pipe, X65 and above with up to 1 in. wall thickness.

The multiple jackscrews on the clamp give the

operator the ability to apply precise reforming pressure

on the exact areas of pipe which are most in need of it.

The specialised torque wrench supplied with the Ultra Rim

Clamp furthers this capability by allowing the operator

to set the exact torque required for the reforming

application. This allows the operator to save time and

effort by setting the perimeter of the jackscrews before it

is placed on the pipe.

The hinged flip-up jackbars on the Ultra Rim Clamp

allow for simple pipe mating, and also ensure that the

clamps can be used for

applications which require

100% weld and/or grinding

without removing the clamp.

Each heavy duty jackbar

also comes with a pivot

pad, which allows for use

on coated or uneven pipe

surfaces. The pivot points

of the clamp are made

from stainless steel so one

clamp will work for all pipe

applications, eliminating

the potential for pipe

contamination. The unique

jackscrews of the Ultra Rim

Clamps are trapezoidal,

which are superior and

stronger than conventional

jackscrews, and can assert

more pressure to the pipe.

The heavy duty latching

mechanism of the Ultra Rim

Clamp ensures stability and

safety on the pipe.

The Rim Clamp and

Ultra Rim Clamp are both

available as CE certified.

Unlike other clamps on

the market, the Sawyer

Ultra Rim Clamps are

supplied with a torque

wrench for correct

reforming pressure of

each jackbar, along with

a unique setting gauge

which allows the operator

to set the jackscrews to

the exact diameter of

the pipe being worked

on, prior to the clamp

being fitted onto the pipe. This saves considerable time

and effort in trying to balance the clamp once it is in

position. With the Rim Clamps, once they are on the pipe

and locked into place; you’re ready to go.

Sawyer is a competitive global provider of pipeline and

welding equipment. With offices in the US and the UK, they

are well-positioned to meet the needs for the expanding

international pipeline industry and can effectively distribute

equipment to customers wherever they are based. Sawyer

offers a diverse range of equipment for welders in the pipeline

industry; setting the benchmark for quality and durability and

consistently manufacturing innovative equipment on which

their customers can rely. All equipment is engineered with

set-up speed, ease of use and maximised productivity in mind,

with dependability and power guaranteed.

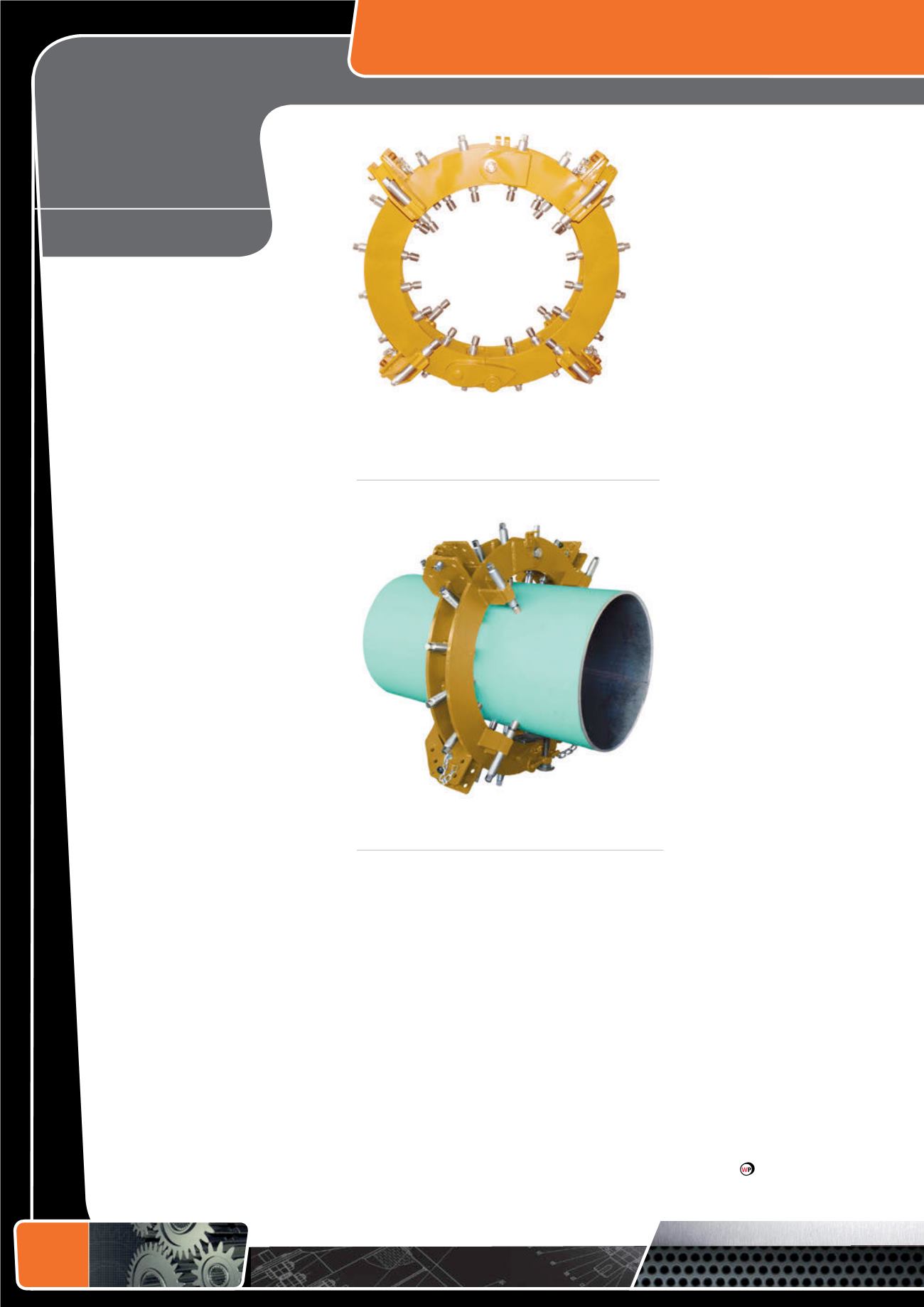

Figure 1.

The Sawyer Ultra Rim Clamp is designed

for use on out-of-round conditions, heavy duty

jackscrews apply pressure to precisely reform the

pipe.

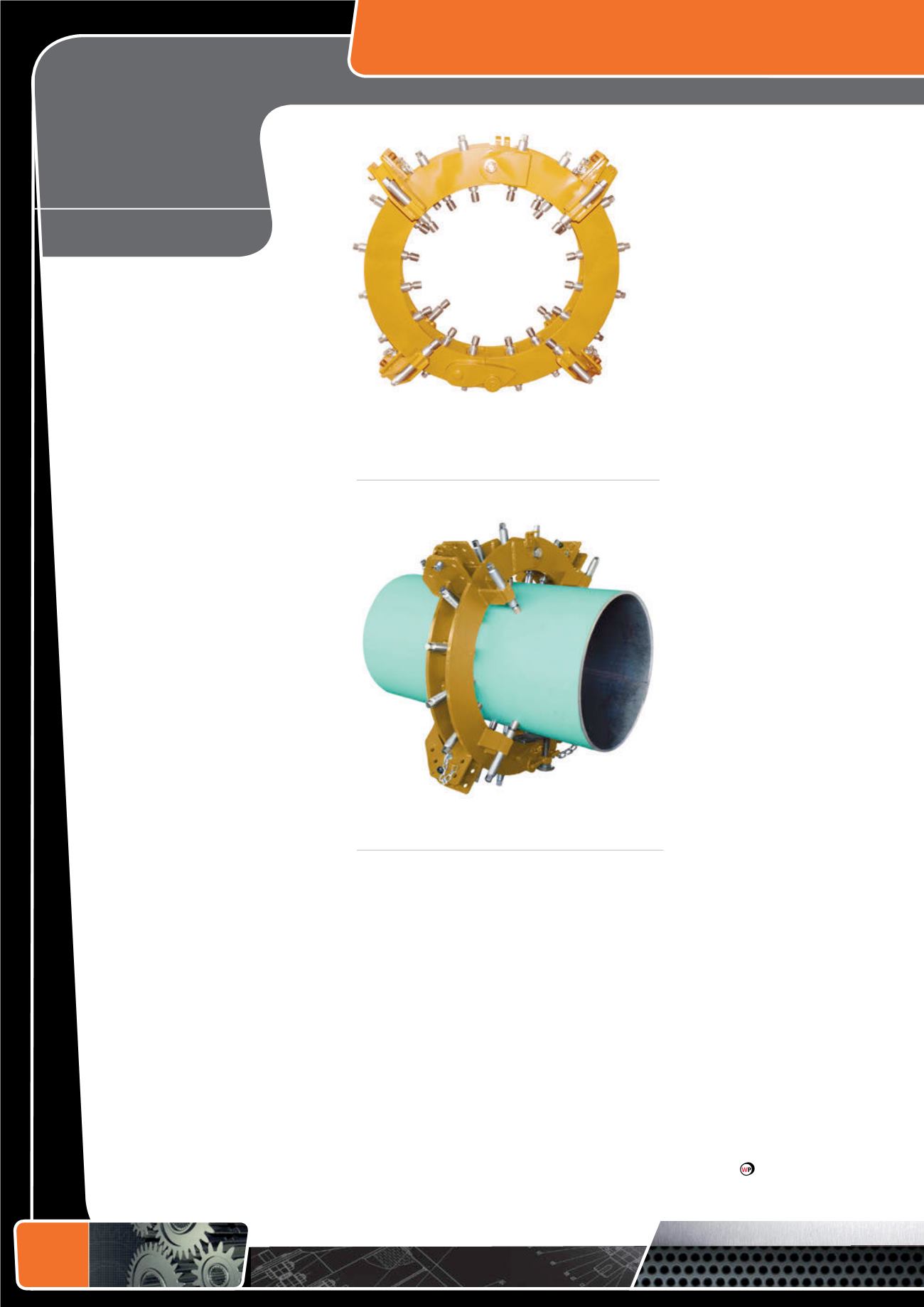

Figure 2.

Save time and effort, by using the

specialised torque wrench to set the perimeter of

the jackscrews before it is placed on the pipe.