26 |

Oilfield Technology

December

2014

drilling tools to the surface, provides ameans of transporting drilling

mud downhole and transmits rotary torque to the lower drill string

components; the drill collars or heavy‑weight pipes, which deliver the

WOB necessary to push the bit into the formation; and the downhole

mudmotor, which provides ameans to steer the assembly and generates

rotation at the bit, independent of drill string rotation. The specific layout

of the lower drill string, typically referred to as the BHA, is critical to the

success of the well. The design of the BHAwill dictate how the drilling

assembly interacts with the formation, thus directly affecting steering

characteristics. In aworld of shrinking drilling targets and optimised oil

extractionmethods, controlling the direction of the well is of utmost

importance to an operator. It is the responsibility of the service company

to ensure that their tools canmeet these needs, set forth by the operator,

both in terms of performance and reliability. As the industry continues

to push the boundaries on drilling, optimisation techniques become

increasingly more important for maintaining success on each of

these levels.

The success of any well starts with themotor as themost critical

component in the directional drilling assembly. While drilling, downhole

motors are consistently exposed to high temperatures, excessive

pressures and heavy loading; even under normal circumstances these

can be limiting factors in the life of a tool. Due to a lack of observable

data regarding the types of forces and loads themotor is subjected to

downhole, development of such drilling components has been done

via a ‘Build and Test’ approach. In this way prototype designs are

iteratively tested until an appropriate configuration passes all necessary

performance and safety assessments. Unfortunately, it is impossible

to test for every drilling scenario as they differ greatly fromarea to

area, and company to company. Thismeans that issues will arise in

the field that will have to be addressed throughout the life of the tool.

Recently, there have been a number of reported incidents relating to

the non‑conformance of specific components of a particular motor.

The incidents encounteredwere primarily related to the bent housing

of themotor, and a knuckle‑joint connection that is part of the internal

drive‑train assembly.

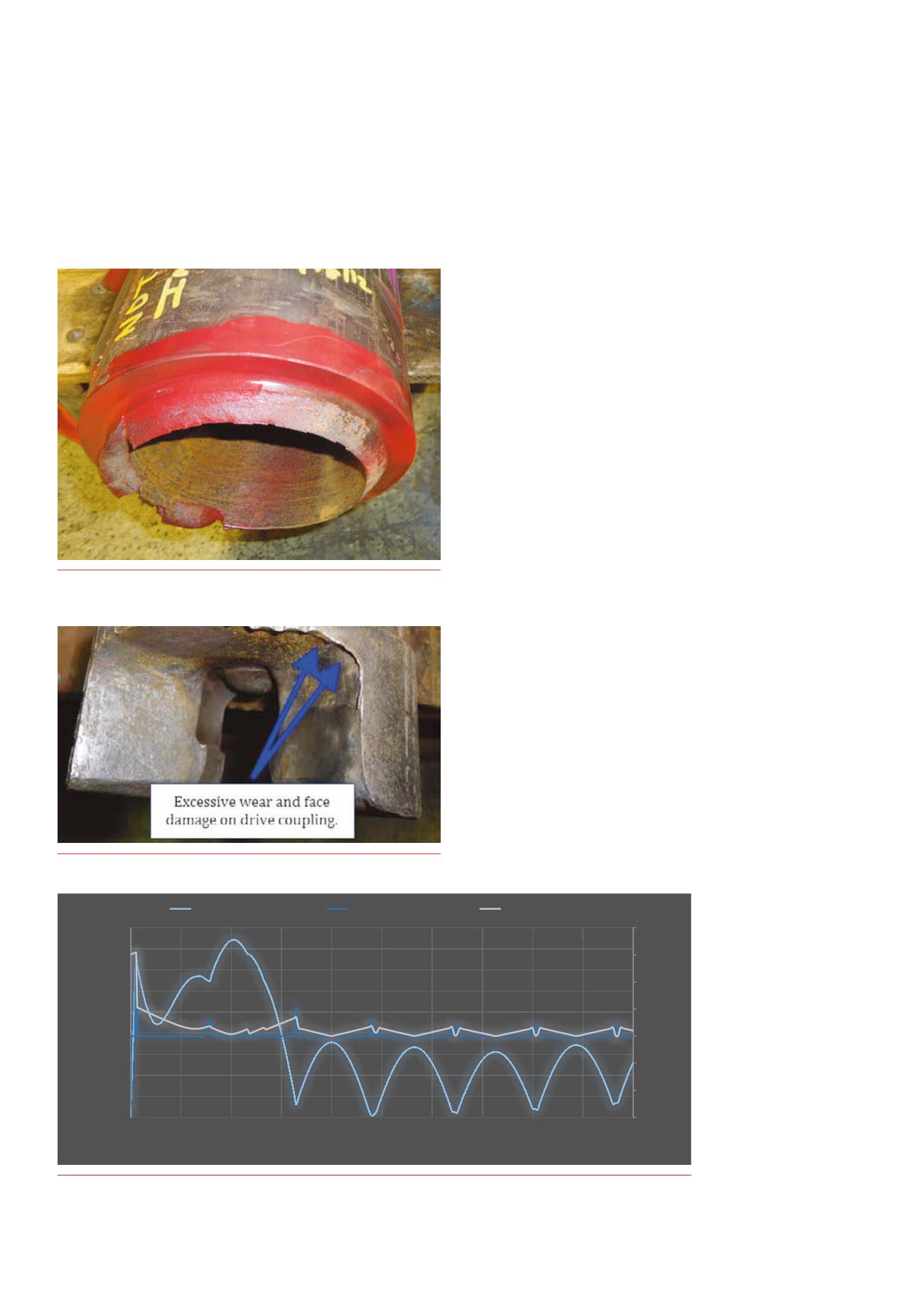

The bent housingwas observed to experience noticeable cracking

near the base of the threads on a number of runs. This suggested that,

in certain scenarios, the thread roots were stressed beyond the limits

of thematerial. In a couple of severe cases this resulted in twist‑offs

(Figure 1) of themotor and subsequent loss of motor parts in the hole.

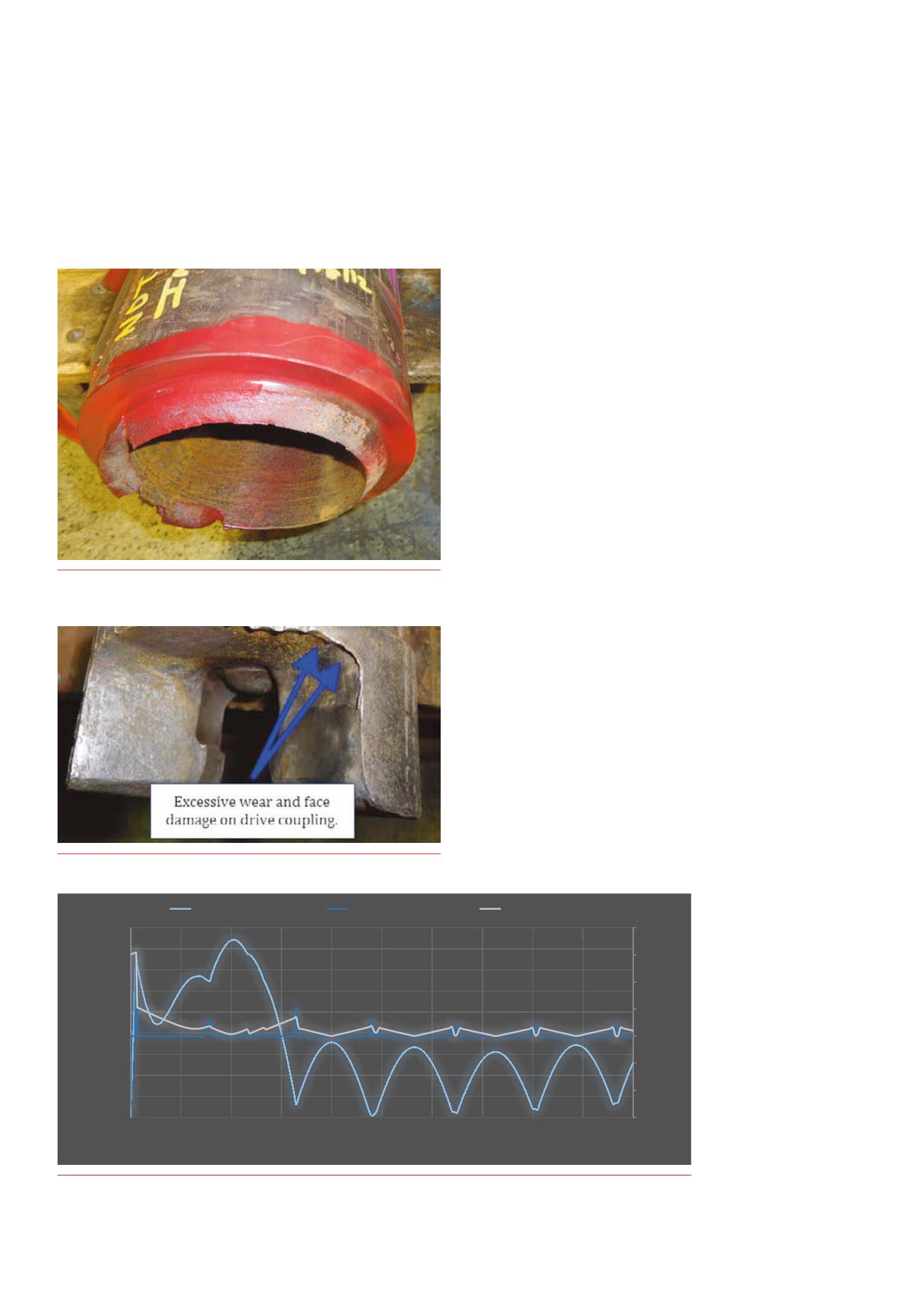

The knuckle joint problemwas less noticeable in the field, but would

be very apparent during servicing. Visual inspection of several motors

revealed that the knuckle‑joints were experiencing excessive wear during

operation (Figure 2), most likely due to stick/slip conditions downhole.

As a result, these parts had to be frequently replaced, resulting in high

maintenance costs and, in some cases, significant NPT.

Engineeredsolutions throughcomplexmodelling

With very limited downhole data available, it is difficult to empirically

determine the forces andmoments acting on the drill string, thus it is

more challenging to design tools that handle those loads. In order to

providemore robust equipment and optimise components to survive

severe drilling conditions, this hurdlemust be overcome. Internally

developedBHAmodelling tools havemade it possible to reliably, and

efficiently, recreate these

downhole loading scenarios

and determine the effective

forces andmoments

acting on the BHA. In

post‑analysis, the drilling

scenarios associated with

a well can be examined

and realistic tool loading

can be calculated based

on what occurred during

a particular motor run.

This type of computation

provides tremendous

insights for root cause

analysis and general drill

stringmechanics.

Figure 1.

Extreme case of abent housing failure resulting in the twist-off

of amotor below the bend.

Figure 2.

Signs of excessivewear ona knuckle-joint component.

-‐6000

-‐4000

-‐2000

0

2000

4000

6000

8000

0

2000

4000

6000

8000

10000

12000

14000

16000

18000

0

20

40

60

80

100

120

140

160

180

200

Drill String Loading

Total Bending Moment (7-‐lbf)

High-‐Side Contact Force (lbf)

Total Shear Load (lbf)

Distance from Bit (5)

Total Bending Moment (5-‐lbf)

Contact/Shear Force (lbf)

Figure 3.

Estimateddrill string loading fromBHA analysis computation.