38

LNG

INDUSTRY

SEPTEMBER

2014

Next, Antero conducted a bid process to choose its

LNG and related services supplier. It ultimately selected

Prometheus Energy, a specialist in providing LNG fuelling

solutions to the oil and gas industry. The following

objectives have been completed and sustained:

To operate safely and reliably at all times.

To reduce costs.

To significantly reduce overall emissions from

operations.

To reduce truck traffic on challenging rural roads and

pad sites.

It is important to note that as the domestic merchant

LNG industry continues to build out, transport distances

will decrease over time, and LNG delivered costs to

customers should become even more competitive.

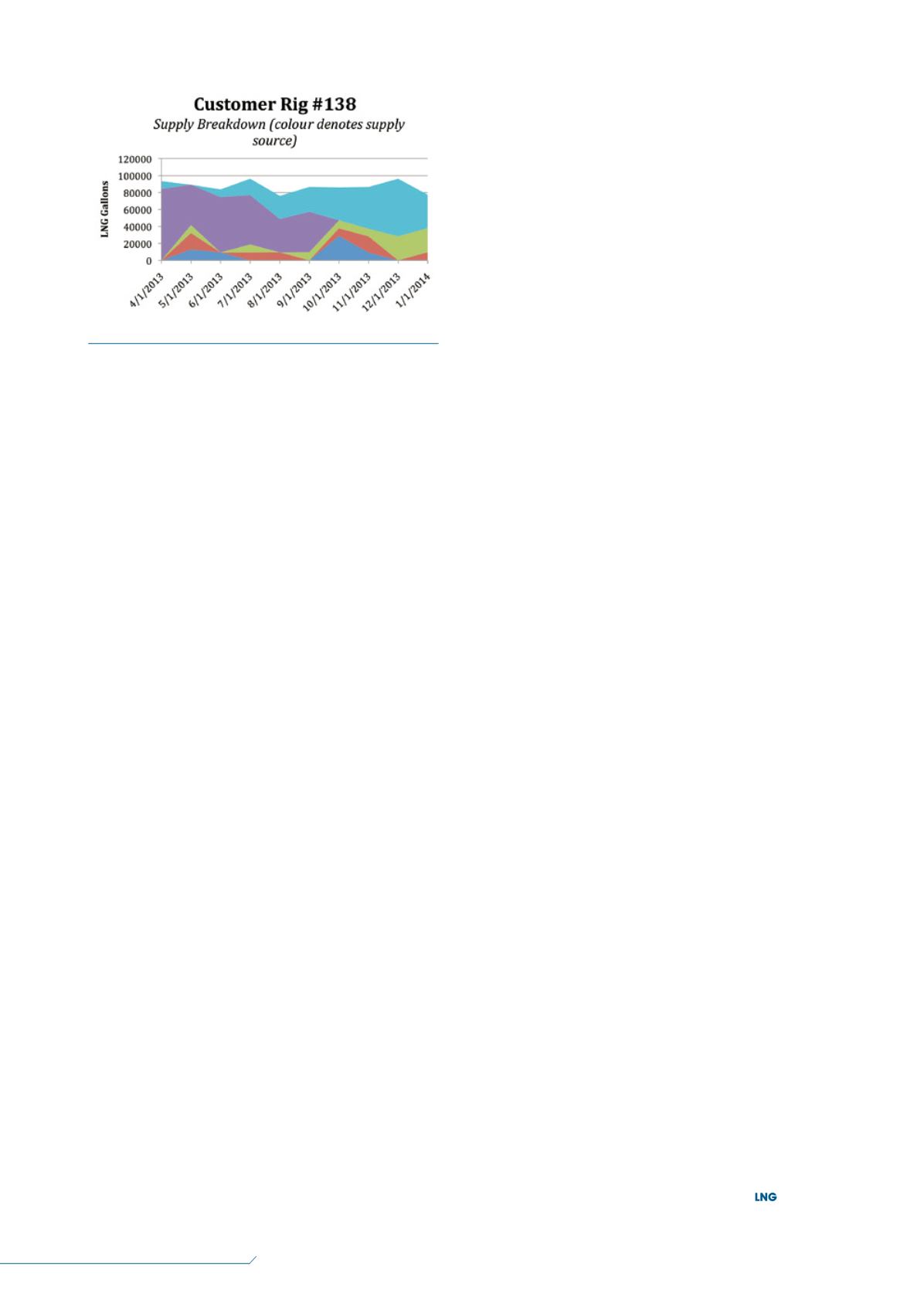

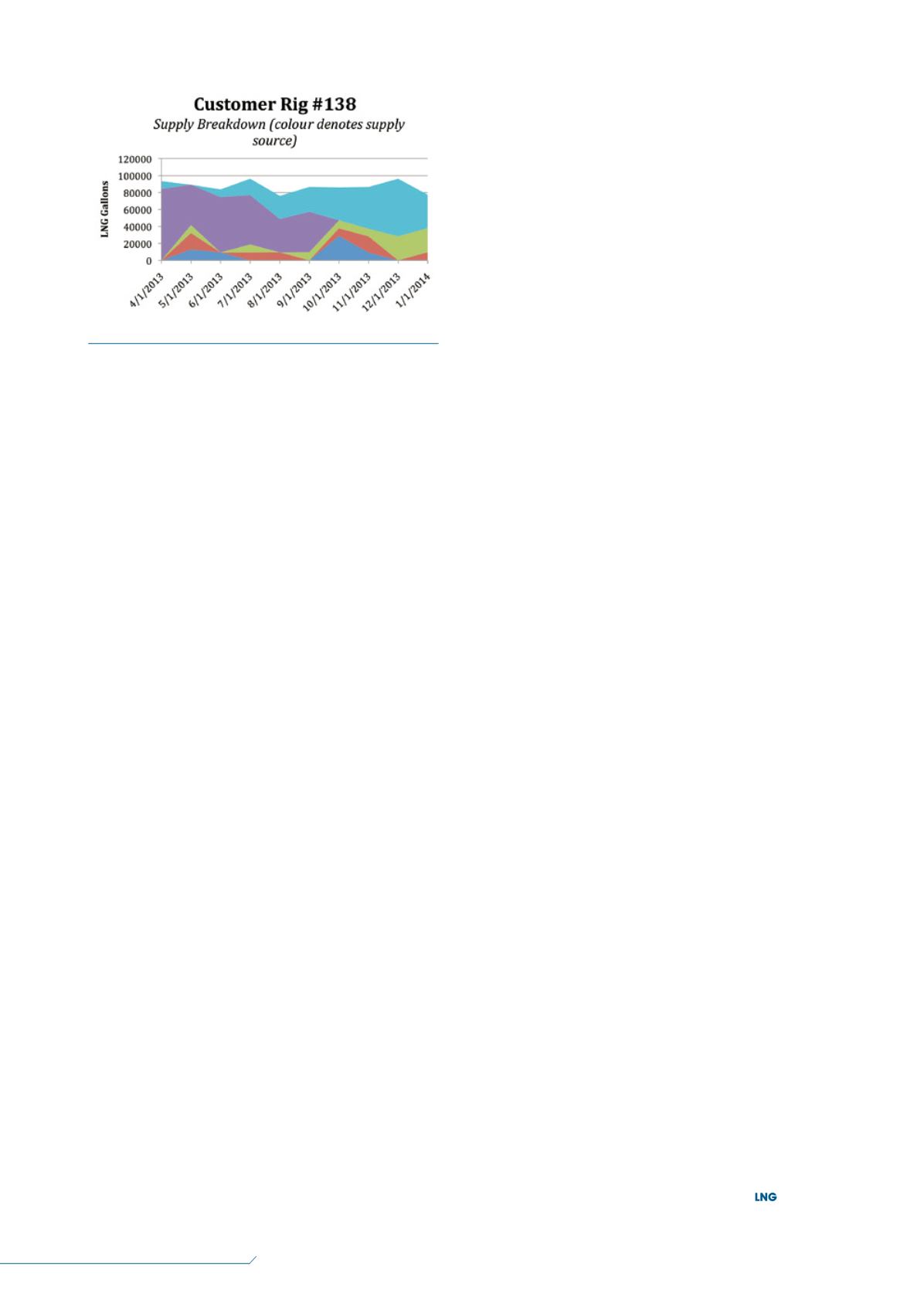

The value of this network supply configuration cannot

be overestimated. Figure 3 presents a visual summary of

LNG deliveries made to one of Prometheus’ drilling

customers in the Rockies, which operates multiple 100%

dedicated gas rigs. Note how many different sources of

LNG may be required to supply one rig. As a result, for its

supply regions, the company will typically have three to

four sources available to customers in order to provide

LNG supply assurance.

As important as LNG supply reliability is to the

customer, the reliability of the equipment to both safely

store and vaporise the LNG to meet the fuel demand of

the rig is equally essential. Prometheus deployed its LNG

storage and vaporisation units (equipped with all the

modules of a safe and reliable LNG fuel platform) to

support Antero’s onsite drilling operations, including a

mobile LNG storage trailer, an integrated electric

vaporiser, a supplemental ambient vaporiser, and an

integrated flow control and emergency shutdown (ESD)

system.

To date, Antero has had Prometheus deploy as many

as seven LNG supply systems to support its transition to

100% dedicated gas drilling operations. For each LNG

supply solution, Prometheus tracks and regularly reports

its total system safety and reliability performance.

Prometheus also maintains on-stream factors in excess of

99.5%.

Conclusion

Many operators have chosen to test natural gas based

drilling by application of dual fuel conversion technology

to existing diesel engines. The results have been mixed.

By its nature, natural gas does not readily burn in a diesel

engine. With a narrow flammability range and a much

higher autoignition temperature than diesel, the injection

of natural gas to a diesel engine has to be done with

precision and care. In addition, the dual fuel system has

to be carefully maintained in order to ensure that mixing

and high diesel substitution rates can be maintained

throughout the entire well drilling time period.

Many third party suppliers rushed to supply these

engine conversion kits several years ago as natural gas

prices fell in comparison to distillate/diesel fuels. The

engine OEM suppliers are now responding to this market

with improvements to their own technology, and at prices

that are deemed more competitive by operators and

drilling contractors alike.

In short, maintaining diesel substitution rates at or

above 50% over the entire drilling cycle has proved to be

a challenge. Initially suppliers claimed 70+% diesel

substitution rates. While this performance can be achieved

under very carefully controlled conditions and across a

very narrow load range on the engine, that level is not

sustainable across the entire drilling load cycle.

Furthermore, diesel substitution is dependent on gas

quality. When using field gas, the presence of NGL

hydrocarbons can de-rate the substitution performance

significantly. Operators have experienced substantial

performance drop-off when moving these systems to

different pad sites with different field gas quality. While

LNG solves this problem by providing consistent quality

from well to well, it is more expensive than field gas.

If diesel substitution rates can be maintained at or near

50%, which is finally being consistently achieved, LNG

supply is not only a simple, easy solution, but it becomes

economic with paybacks on the added investment for dual

fuel conversion kits typically less than 12 - 18 months.

In addition, field gas can be economic in the dual fuel

application and even at lower diesel substitution rates,

provided that the field gas conditioning equipment can be

readily moved to new locations and that the equipment is

well maintained. It is also important to note that when the

field gas quality changes, the dual fuel kits must be

recalibrated to provide the unique diesel substitution

profile required by the specific field gas quality. One big

advantage of LNG is that the quality is consistent from

well-to-well. This significantly simplifies the process for

dual fuel usage and does not require frequent recalibration

of the dual fuel kit.

Prometheus, along with many operators, understands

the significant economic advantage of 100% gas drilling

over dual fuel operation. The LNG equipment (and cost)

required is similar, yet the fuel savings are doubled in

dedicated gas drilling, thus providing paybacks of less

than one year, even when using LNG in most cases. Antero

Resources has demonstrated an innovative approach to

maximising 100% gas drilling, and it has paid off in more

than just a monetary fashion as it continues to accelerate

asset development in the Appalachian basin.

Figure 3.

Sources of LNG supply.