36

LNG

INDUSTRY

SEPTEMBER

2014

that has historically been underserved. Antero has converted

over 80% of its drilling fleet from diesel to 100% natural gas

fuelling.

Taking action

Leveraging its knowledge in developing unconventional

reserves based on previous experience in the Barnett,

Woodford and Piceance Shale Plays, several years ago Antero

made a decision to commit 100% of its resources to build and

develop a leading production position in the Appalachian Shale

Basin (Marcellus and Utica Shale Plays).

When an exploration play is rapidly developed into

producing assets, environmental issues can challenge

objectives and schedules. Antero’s strategy to develop its

Marcellus/Utica reserves was partly based on the transition of

its drilling and completions operations from diesel fuel to a

100% natural gas platform.

The company planned to maximise use of very low cost

wellhead gas as much as possible, but knew that its raw

wellhead gas contained significant amounts of NGL

hydrocarbons. Antero also needed a gas supply solution when

drilling in new, undeveloped areas so that it could utilise its

drilling rigs 100% of the time. It required a consistent, reliable

and repeatable solution, and while recognising that natural gas

use for fuelling its rigs and frac fleets could significantly

improve its bottom-line, the company was also committed to

the issues of safety and the environment. As such, the

company executed the following strategies throughout its

drilling operations:

Working with two large contract drilling companies

(Patterson-UTI and Precision Drilling), Antero decided to

implement 100% gas drilling over the long-term using

GE-Waukesha’s ‘rich-burn’ gas engine technology.

It began converting its regional vehicles to natural gas

combustion (NGV).

It commenced construction of a central frac ‘flowback’

water treatment facility that will allow the company to

recycle over 90% of its water consumption requirement in

frac operations.

Gas drilling solution

In 2012, Antero set out to find strategic partners to address

its challenges for designing a 100% gas-fuelled drilling

platform with a primary goal of utilising wellhead gas as much

as possible, and also providing a reliable fuel supply when

wellhead gas was not available.

The company worked with its primary drilling contractors

to explore gas engine technology that would be able to

efficiently utilise wellhead gas over a wide range of gas quality.

It also wanted these rigs to operate with extreme reliability

and, most importantly, be readily accepted by the drill rig

operators. GE-Waukesha, working closely with Patterson-UTI,

provided just such a solution. Patterson-UTI chose the

Waukesha rich-burn gas engines for the following reasons:

The Waukesha spark-ignited gas engines are able to

operate without a load bank, meaning that the drilling

technician experiences diesel-like performance from a

natural gas engine. As a result, the transition to rich-burn

gas engines was relatively easy from an operator’s

perspective.

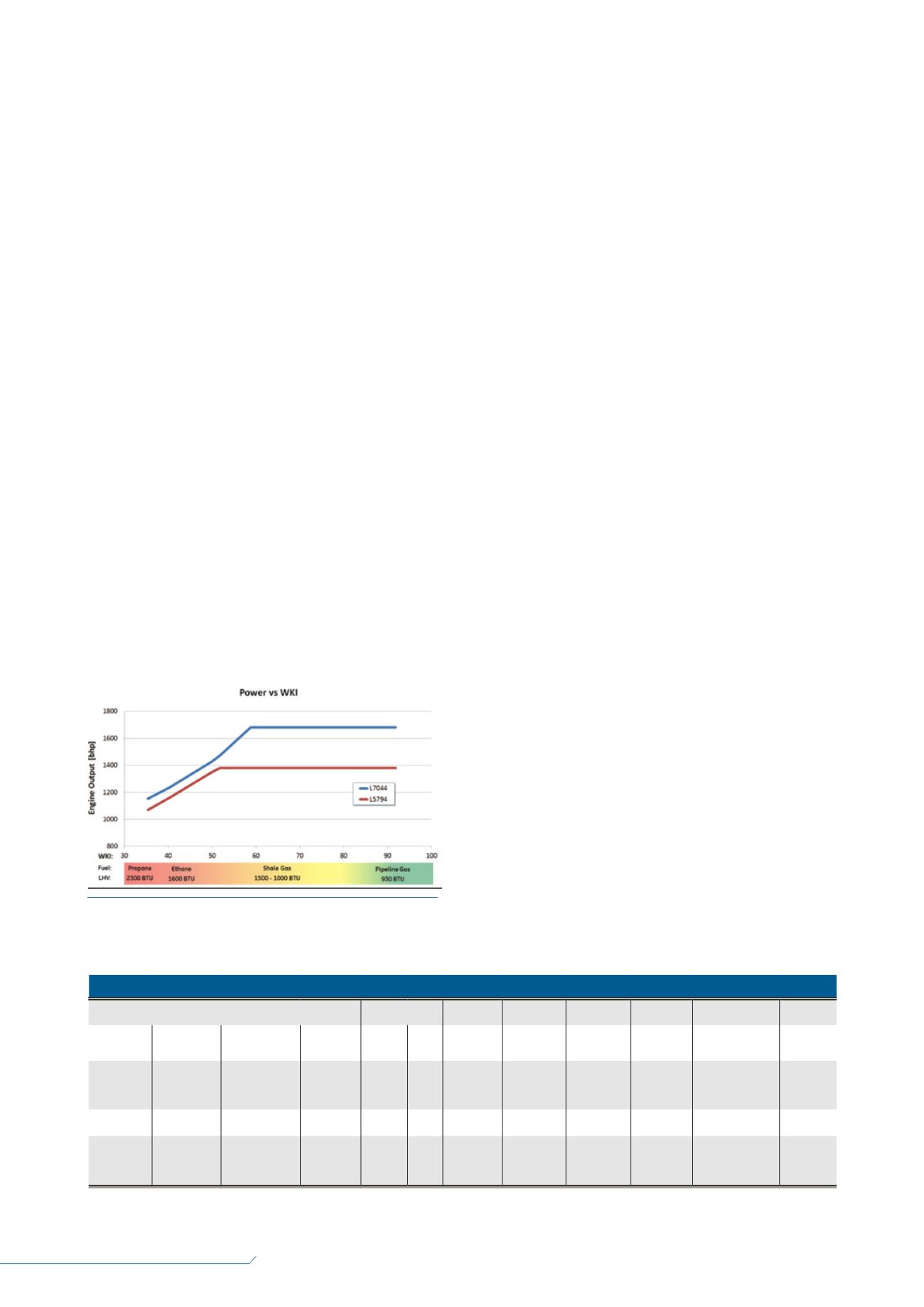

The Waukesha engines, both the 1.0 MW (L5794) and

1.2 MW (F7044) models, could handle very hot (high BTU)

field gases, which enabled the gas engine powered drill

rig to operate on field gas in almost any shale formation.

This fuel tolerance is highlighted in Figure 1, which shows

that the engine power output can handle rich gases up

1650 Btu/ft

3

without ‘knocking’ (power vs. Waukesha

Knock Index).

The Waukesha engines could achieve US Environmental

Protection Agency (EPA) mobile certification on field gas.

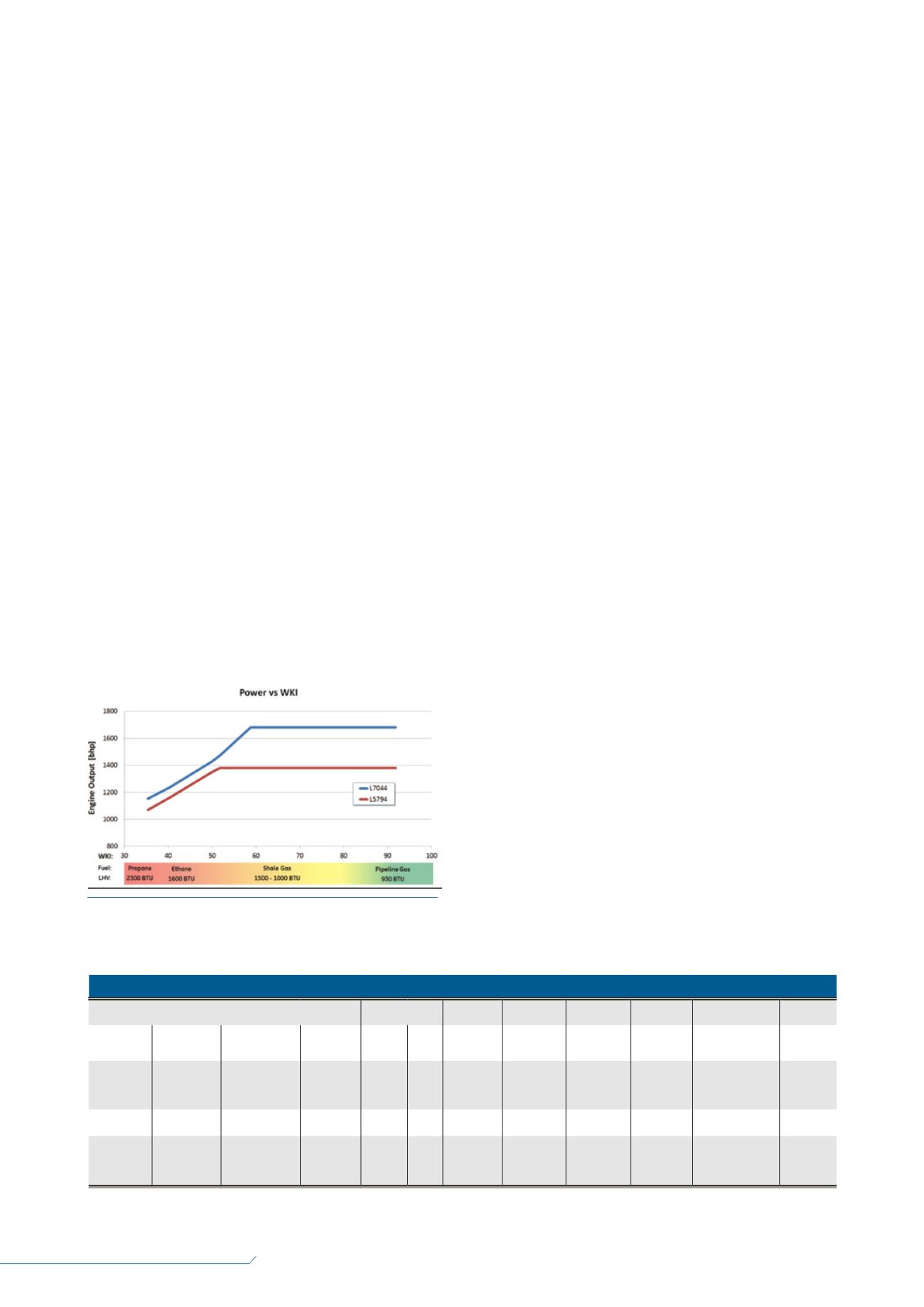

In addition to the performance aspects, the Patterson-UTI

team also considered the emissions profiles of various drilling

engines available on the market. These data are provided in

Table 1.

Figure 1.

Waukesha engines power output operating on

various fuel compositions (LHV). (Source: GE-Waukesha.)

Table 1.

Engine emissions (Source: GE-Waukesha)

Power

NO

x

CO

NHMC PM Methane slip CO

2

Model

Three-way

catalyst

Fuel

Load (%) bhp kW g/bhp-hr g/bhp-hr g/bhp-hr g/bhp-hr g/bhp-hr

g/bhp-hr

7044GSI

Y

Commercial

quality natural

gas

100% 1680 1253 0.28

1.3

0.03

0.001

1.23

542

3512C N

Diesel

100% 1476 1101 6.20

0.19

-

.03

-

465.7

5794GSI

Y

Commercial

quality natural

gas

100% 1380 1029 0.32

1.8

0.02

0.001

1.06

524