In the beginning

Boskalis’ strength is its ability to undertake projects in a variety

of circumstances and in diverse locations. To meet the high

quality of service expected by its clients, Boskalis organises itself

by sourcing logistics support, entering into subcontracts with

suppliers and setting up offices.

Once offices were established in Darwin and sufficient

accommodation was secured, Boskalis entered into an agreement

with local suppliers and major local subcontractors for, amongst

other things, the procurement of approximately 750 000 t of rock.

Local vessels were obtained to support the dredging campaigns

and to bring onboard resources to carry out the shore approach

works, including the procurement of a 600 t linear to perform the

pipe-pull.

Rocking in the top end

The quarries being utilised to source the required 250 000 t of

filter and 500 000 t of armour rock are located approximately

100 km from Darwin. The rock is quarried and transported in quad

road trains to the intermediate stockpile areas located close to

Darwin’s East Arm Port, where the rock load out facility will be

located.

HBOJV is the Darwin based joint venture contracted by

Boskalis to produce and transport the rock. Boskalis recently

congratulated the HBOJV transport team for reaching a

1 million km incident and injury free milestone. Using local drivers

with good knowledge of Darwin and surrounding areas, the team

has safely and successfully transported 500 000 t of rock from

Mount Bundey quarries to the intermediate stockpile areas since

June 2013.

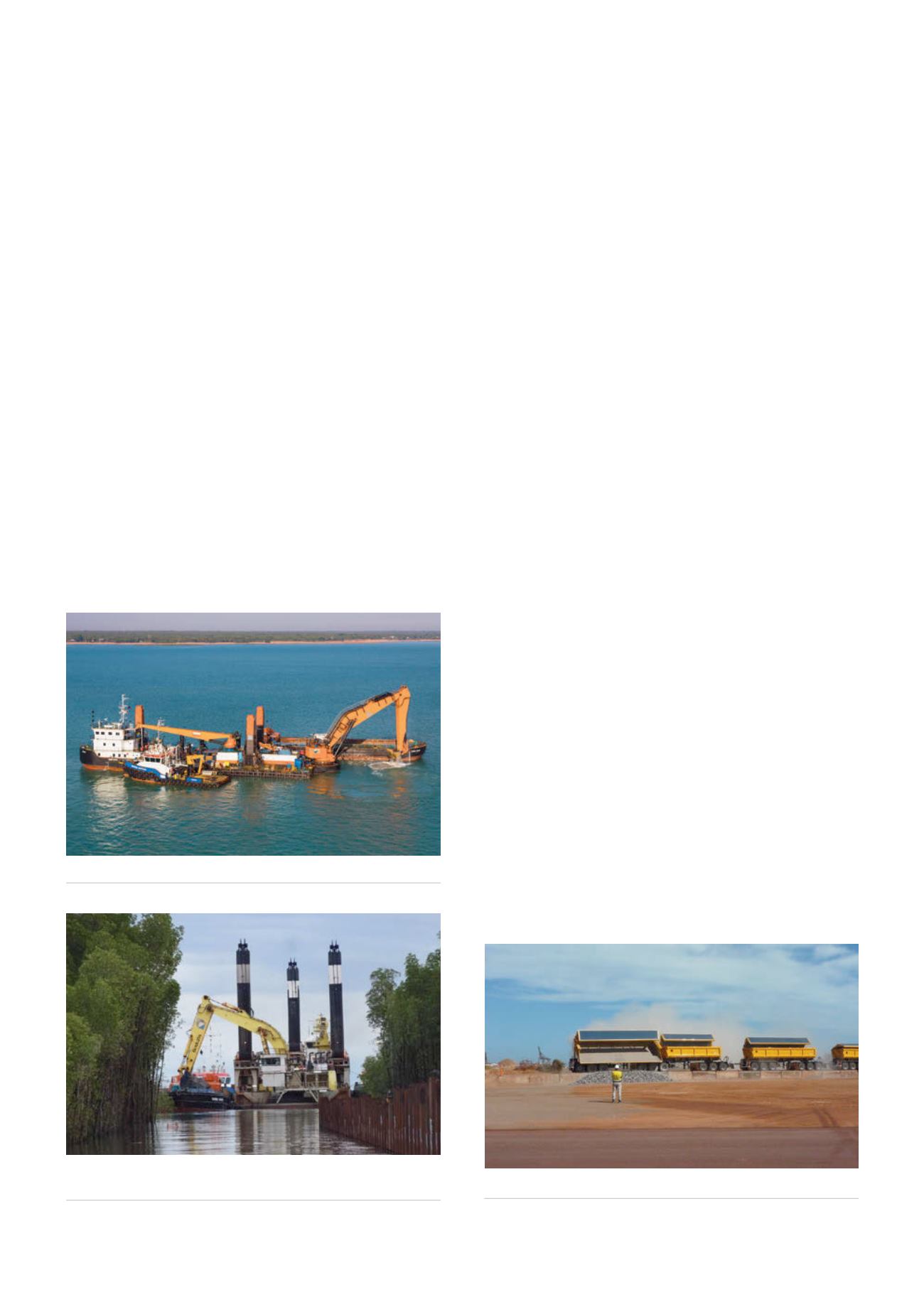

Trench dredging

The trench was required to be dredged over a length of

approximately 16 km, in varying soil conditions and at various

depths, leading Boskalis to deploy a number of different dredgers.

Dredging was initially executed with the trailing suction

hopper dredger (TSHD)

Queen of the Netherlands

, which

removed the soft overlying material. The remaining offshore

trench profile dredging was undertaken utilising the backhoe

dredger (BHD)

Baldur

and the backacter (BA)

Simson

, supported

by self-propelled split hopper barges and shallow drafted non-

propelled split hopper barges for the shallower sections of the

trench.

Offshore, pre-sweeping 60 km from Darwin Harbour was

undertaken utilising the TSHD

Queen of the Netherlands

and some

nearer shore pre-sweeping was undertaken with the BA

Simson

and the BHD

Baldur

.

Near shore, the BHD

Baldur

carried out bedding layer dredging,

following which a filter bedding layer was placed.

Shore approach

Prior to the pipelay commencing, a shore approach needed to

be constructed in difficult and varying soil conditions. Initially, it

had been the intention to construct an open trench through the

entire shore approach, but this was not possible and a cofferdam

was required through the most challenging soil conditions in the

mangrove swamp area. An open trench was constructed through

the salt flat, but the soil conditions in this area also proved to be

extremely soft and various work methods were required before

the trench was completed.

Pulling the pipe

A 600 t linear winch was mobilised and installed at the beginning

of the trench at the shore approach. Together with 3300 m of

121 mm dia. wire, the winch was used to pull the pipe from the

pipelay vessel

Semac 1

onto the shore. Buoyancy tanks were

installed on the pull wires and a number of pipe rollers were

installed in the trench to assist with the pull.

Figure 2.

Backacter

Simson

.

Figure 4.

Rock delivery.

Figure 3.

Backhoe dredger

Baldur

dredging the shore

approach.

74

World Pipelines

/

SEPTEMBER 2014