for project managers. The testing performed under the supervision

of TÜV, however, provides a clear overview of the performance of

available pipe-end protection solutions and makes the selection

of the best product easy.

Three tests to establish performance

Dhatec aims to position itself as the number one supplier when

it comes to quality and highly specialised pipe-end protection

products. In order to achieve this, Dhatec has set up a certification

programme with the well-known, independent underwriters

company TÜV-Nord. Dhatec and TÜV have determined a test

programme in which three different tests are conducted. The

tests are performed in order to distinguish the performance of the

different available solutions.

The first test is designed to establish how strong the pipe

closure solution or bevel protector is when clamping itself to

the pipe-end. A high clamping force is needed to guarantee that

the bevel protector or pipe cap will not fall off the pipe during

logistics due to temperature fluctuation, wind load or hook

lifting. The test was designed so

that weights pulled on the product

on the pipe. By adding weights, the

point at which the specific pipe-end

solution was pulled out of the pipe-

end was found. The results range

from as high as 500 kg pulling load

on a bevel protector, to only 50 kg

pulling load on a simple pipe cap.

The second test was done to

establish the level of water and

dust resistance of the different

pipe closure solutions. Tests are

performed according to the norm

IEC 60529 and result in a certain IP

classification. To keep the pipes in good condition during storage

and transport, it is necessary to decide to which degree the pipe

needs to be protected. Is some degree of dust and water in the

pipe allowed? Or is it necessary to seal the pipe completely

against rain and dust? This test resulted in high IP-44 classifications

but also in IP-40 classifications where water can get into the pipe.

The third test was done to establish to which degree the

solution protects the pipe-end against impact forces. As well as

bevelled pipes needing protection against damage, unbevelled

pipes and offshore weld preparations need to be protected

against excessive damage. An offshore impact test tower was used

to drop a weight of 505 kg from various heights until damage was

found on the pipe-end. Differences in results range from drop

heights as high as 3.75 m for combinations with the steel bevel

protector to as low as 0.1 m for simple pipe caps.

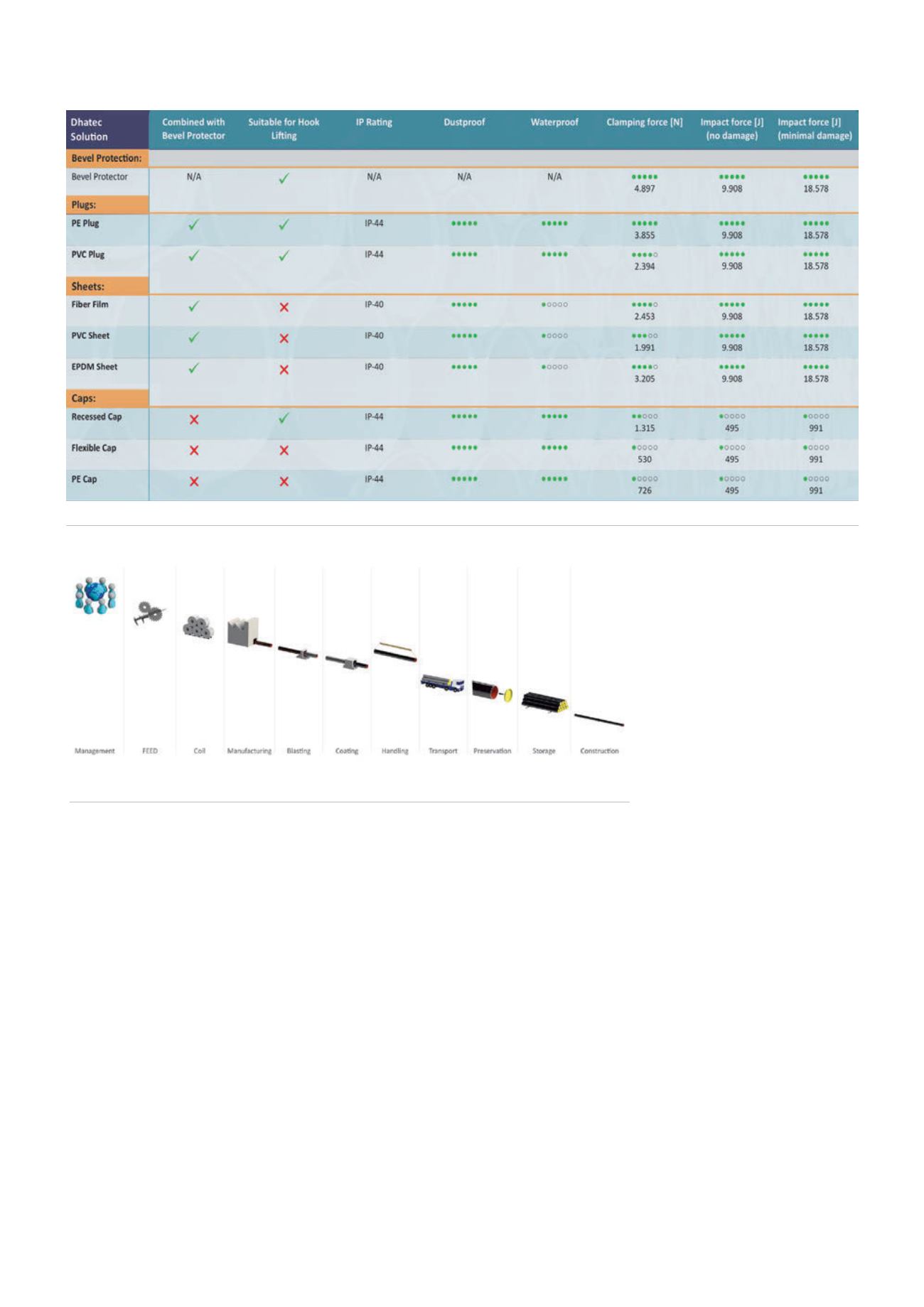

All test results have been displayed graphically in a table in

order to easily distinguish the level of protection offered by each

solution. This enables project managers to select the best solution

for their project.

Figure 2.

Pipe closure selection table: making the best selection for pipe-end protection and closure.

Figure 3.

Task environment: line pipe supply chain.

66

World Pipelines

/

SEPTEMBER 2014