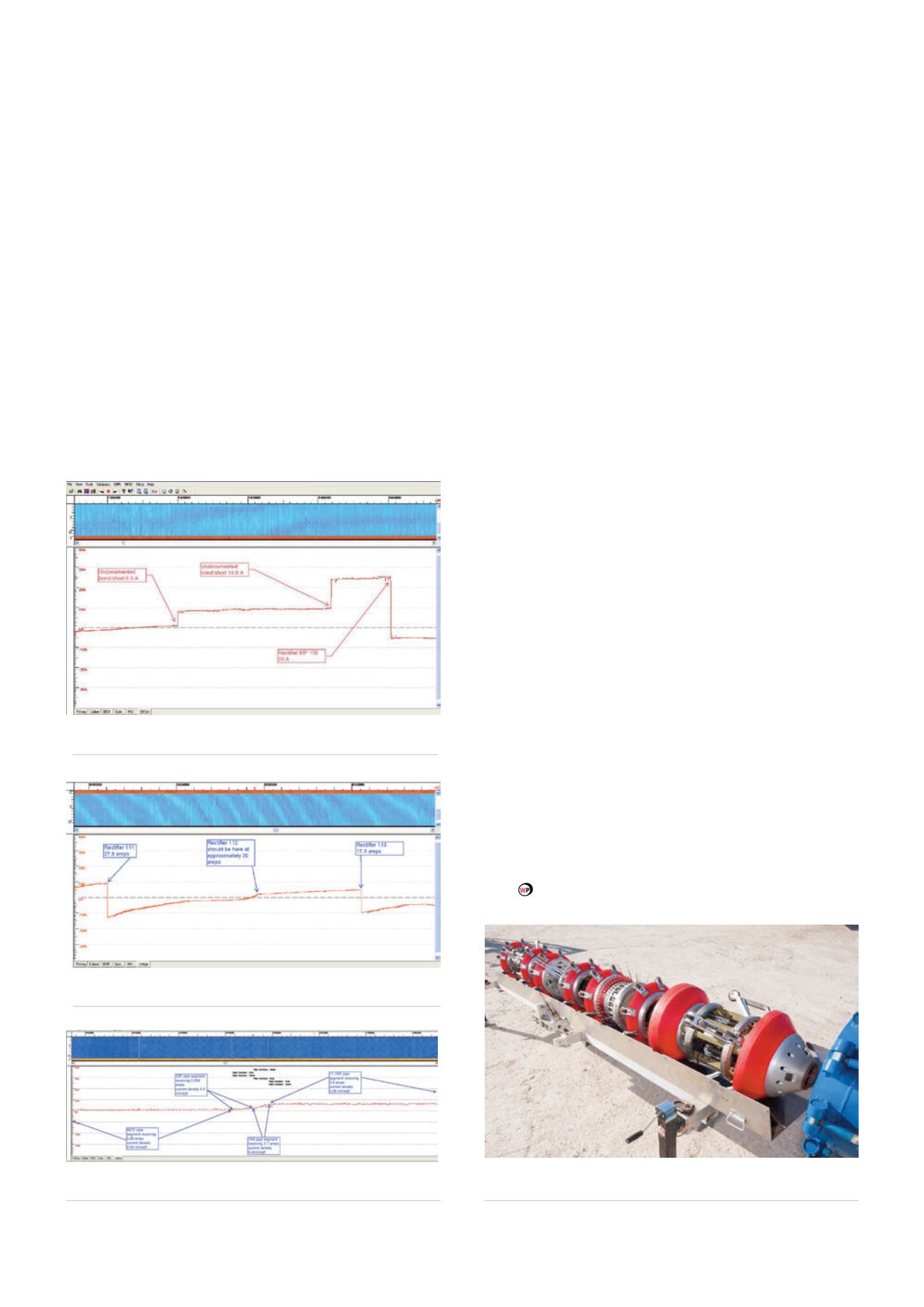

bonds existed. A CPCM inspection confirmed this suspicion

and found 27 undocumented bonds that were stealing more

than 200 amps of protective CP current away from the one

active pipeline (Figure 4).

This same inspection revealed that approximately 30%

of the current from the CP system was being wasted and

was not protecting the intended pipeline. However, it was

protecting the abandoned parallel pipelines as well as the

power company grounds due to these undocumented

bonds.

There is great value in learning that a CP installation

that had been thought to protect a particular pipeline for

many years was not found in the axial CP current data. In

this particular instance, the negative drain cable from the

rectifier was found to be connected to a different structure

rather than the intended pipeline. This condition had gone

unrecognised for many years and was only discovered

because the company looked at the new data set collected

by CPCM (Figure 5).

Another way an additional dataset like CPCM can

reduce uncertainty is by giving pipeline operators a better

understanding of the pipeline coating condition. CPCM

accomplishes this by measuring the CP current that the

pipe is receiving over a given area in real time. There is a

direct relationship between CP current density and pipeline

coating quality, except in the case of disbonded and

shielding coating. During the analysis of the axial CP current

data, the pipeline is segmented where CP current slope

changes are found.

These segments are tabulated with information listed,

such as length of segment, start and end points, surface

area and amount of CP current received. This makes it

quite easy to see, at a glance, the high and low current

density segments. The axial current plot makes it quite

simple to identify changes in coating quality, as can be

seen in Figure 6.

Importance of knowledge

As stated previously, knowledge is the key to reducing

uncertainty in the life of pipeline integrity. Using all of the

tools available to collect CP data during inspections and

testing allows operators to gain knowledge about pipelines

and pipeline CP systems, which leads to much better

decision making and reduced risk. The different datasets

that are gathered to assess pipeline integrity are useful in

reducing uncertainty when used with enhanced knowledge.

However, the datasets become much more powerful and

valuable when integrated and evaluated together in a formal

process. Axial CP current data adds one more layer of vital

information that was not available until the development of

CPCM technology. Axial CP current data can be used to help

pipeline integrity personnel better understand a pipeline

and the CP system that protects it from hazards. Keeping

people, property, and the environment safe from harm

should be our primary goal. Developing a more complete

understanding of the true condition of a pipeline and the

pipeline CP systems will allow everyone to sleep better at

night.

Figure 6.

Coating quality changes identified by current density

changes.

Figure 5.

Missing CP rectifier that was not connected as

reported.

Figure 4.

Undocumented CP bonds discovered by CPCM

inspections.

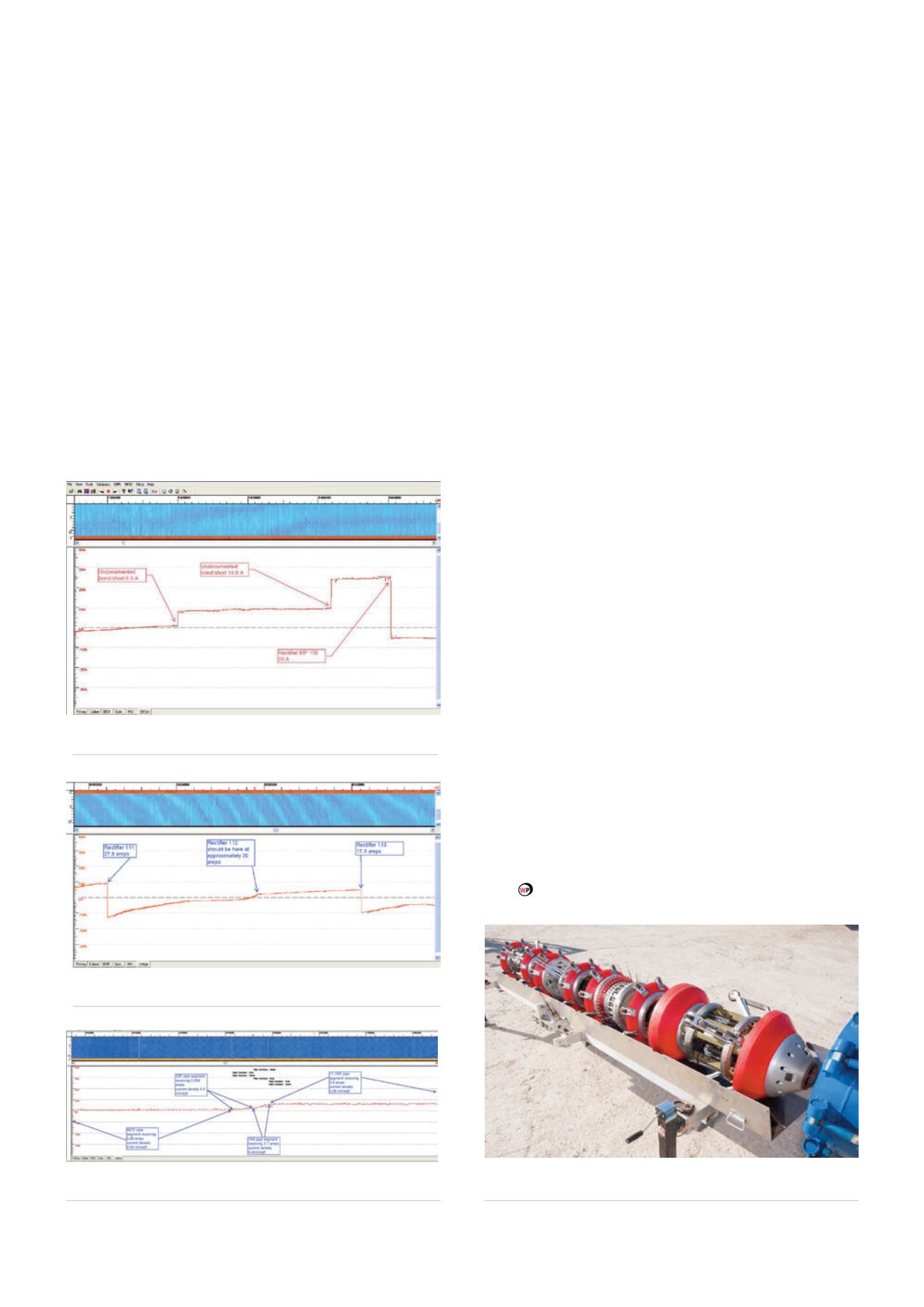

Figure 7.

CPCM tools provide another dataset to help

understand the effectiveness of a pipeline CP system.

46

World Pipelines

/

SEPTEMBER 2014