the business, some operators may use antiquated methods

to monitor CP system effectiveness. While these out-dated

methods may satisfy most regulatory requirements, they

may not provide the utmost confidence that the pipeline

is fully protected in all cases. Therefore, Shell and Baker

Hughes developed a tool that provides another dataset to

help understand the effectiveness of a pipeline CP system.

The CPCM

TM

tool measures the actual voltage drop in the

pipe wall that is caused by the CP current and converts this

value to a current using a simple Ohm’s Law calculation. This

axial CP current value is plotted against pipeline footage for

an unprecedented view of the current distribution along a

pipeline.

While there are no specific regulations that prescribe a

minimum required CP current density to achieve adequate

protection, axial current data provides unique insight into

exactly where and how much current collects on the pipeline.

By analysing the data, significant information about the

pipeline, including the pipeline coating and the CP system

effectiveness, is provided. CPCM provides a very critical piece

of the CP puzzle that could not be evaluated in previous

years.

Since operators are typically under serious budget

constraints, they may be unwilling to use new technology

unless it meets a specific regulatory requirement. However,

there are tools available that go beyond those required by

regulations and help operators to avoid pipeline failures. The

safety of people, property and the environment must always

take precedence, leaving no room for shortcuts in the pipeline

integrity management world.

When assessing pipelines, “what you don’t know” can be

much more important than “what you do know,” especially

in the case of pipeline corrosion and CP. One standalone

dataset rarely tells the entire story on its own. One way to

decrease uncertainty is to integrate as much data as possible

in an effort to identify all possible integrity threats, even those

hidden in areas where conventional test methods were not an

effective method of detection.

At present, CPCM inspections may not directly replace a

close interval potential survey (CIPS) since there is currently

no recognised criterion for CP current (although one is now

under development); however, the two definitely complement

one another. In an interrupted CIPS, the data is only accurate

if every current source/drain is identified and cycled. Failing

to interrupt one source or drain can invalidate an entire

survey, and this problem is exacerbated by the fact that

the existence of hidden sources and drains may never be

found using conventional survey techniques. CPCM excels at

identifying every CP current source and drain on a pipeline.

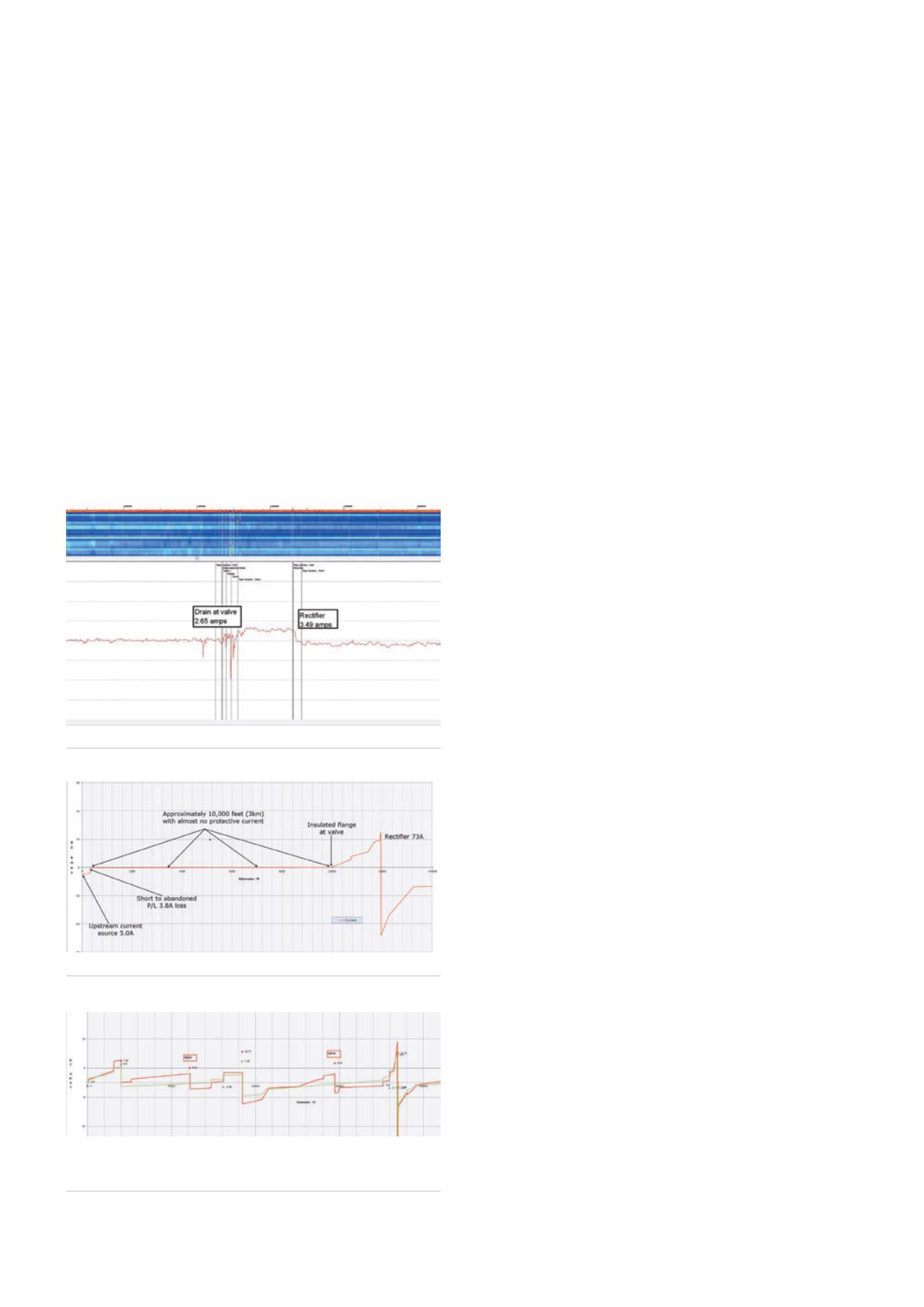

A recent CPCM inspection found that almost every valve site

on a particular pipeline was the site of substantial loss of CP

current due to grounded motor operator electrical conduit

(Figure 1).

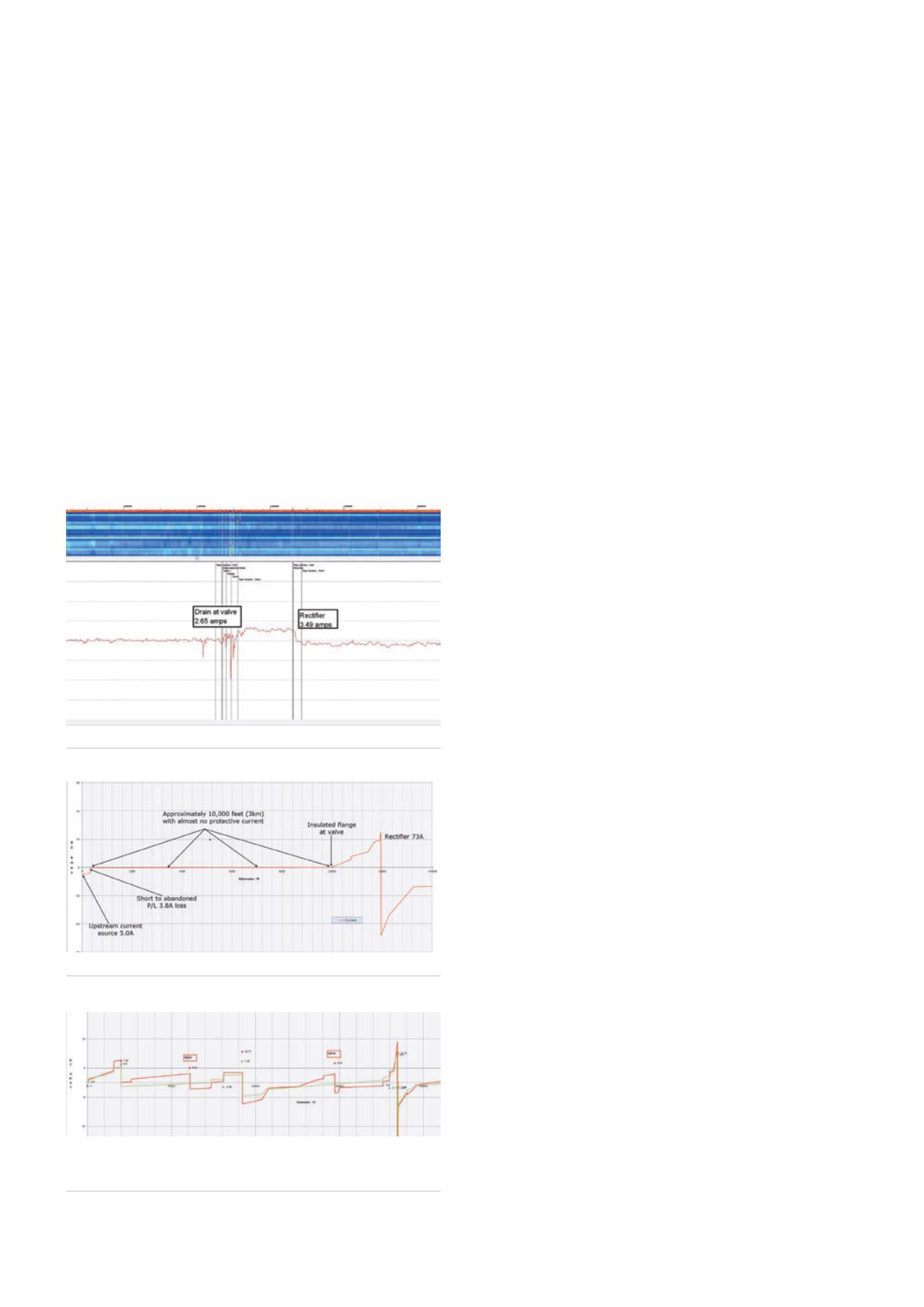

Axial CP current data can reveal much about the

performance of pipeline CP systems, including findings that

call for immediate attention, or it may confirm that the

pipeline is being well protected. In Figure 2, a CPCM inspection

revealed a short to a foreign pipeline and an undocumented,

underground insulated flange that left approximately 10 000 ft

(3 km) of pipeline with little or no protective CP current across

a major waterway.

One operator used CPCM data from a 2011 inspection to

identify areas of low CP current density and then planned

eight additional CP rectifiers and anode beds. A subsequent

CPCM inspection made in 2013 after the installation of the

additional CP rectifiers confirmed they were installed in the

optimum locations. An overlay of both of these inspections

can be seen in Figure 3. It is plain to see that the new CP

rectifier installations significantly increased CP current density

in areas that had previously been low.

CPCM has been used to locate and size previously

unknown bonds to parallel pipelines. In this case, one pipeline

was all that remained active in a multiple pipeline corridor. All

of the pipelines had been protected by a common CP system.

It was suspected that many undocumented, underground CP

Figure 1.

Unwanted CP current drain at a valve site.

Figure 2.

Unprotected pipe discovered in a critical area.

Figure 3.

Comparison of CP changes using two CPCM

inspections confirmed that CP rectifiers were installed in

optimum locations.

44

World Pipelines

/

SEPTEMBER 2014