T

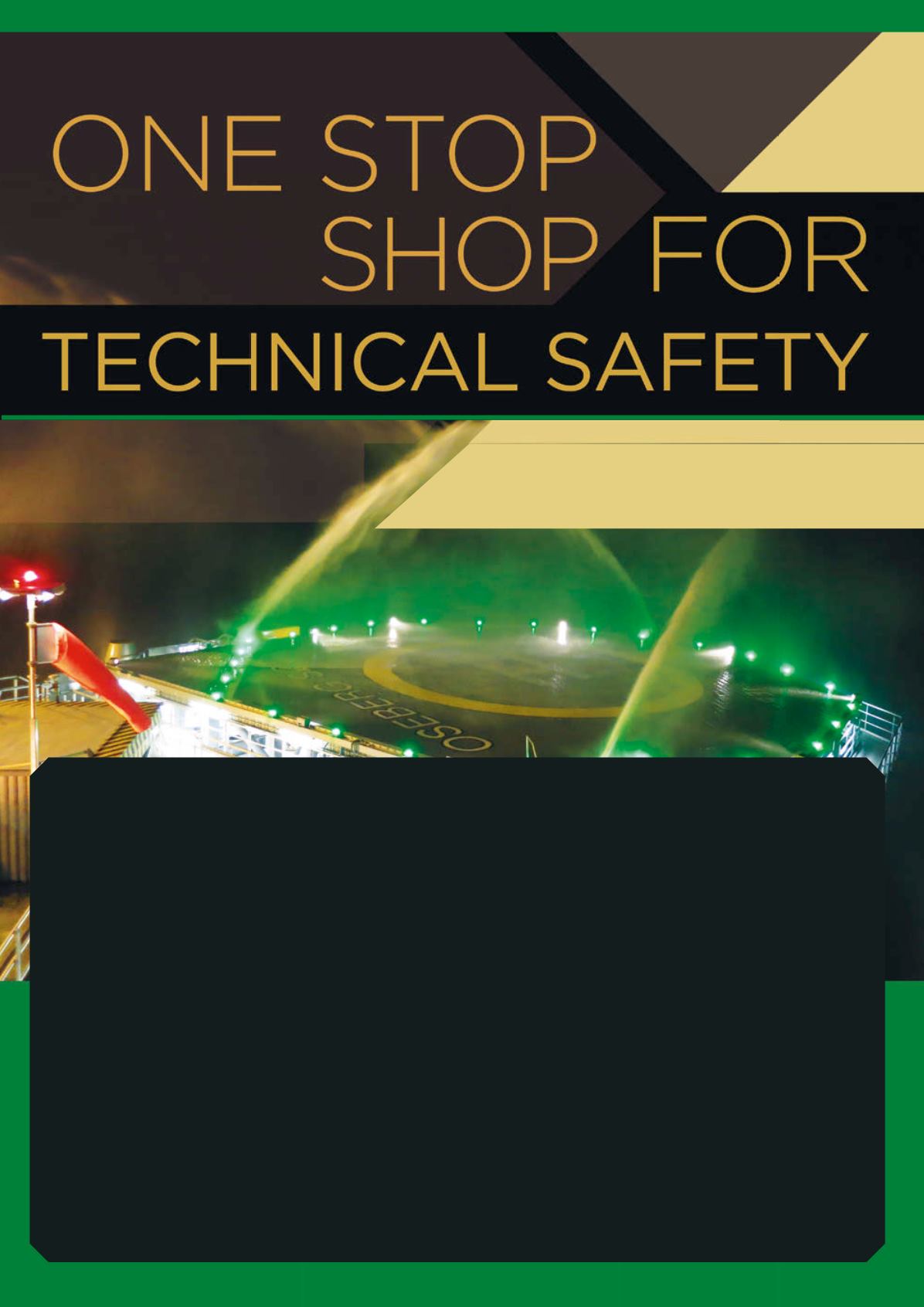

echnical safety is the lastmajor sector within oil and gas still

weighed down by fragmentation. The largest safety suppliers have

already aligned their safety products and expert skills, offering both

regulatory compliance and retrenchment for operators ready to integrate

safety throughout their project architecture.

Services such as active fire fighting, safety automation and pump

systems are still largely purchased and operated on a component basis.

Since its incorporation in 2010, ALIGN, a supplier of bundled technical

safety and total fire fighting solutions for the global oil and gas industry,

headquartered inNorway, has pioneered a holistic shiftof safety thinking

in the oil and gas industry. Such a perspective has also been prevalent in

themedia after the tragic Deepwater Horizon accident the same year. The

investigation report revealed flaws in the real time safetymanagement of

the platform, but also aworrying lack of long‑termsafety decisions during

engineering design and development of newplatforms.

Although a shiftof thinking in a holistic direction has beenwidely

recognised as the correct development for the industry, the oil and gas

operators have yet to apply corresponding newmethods on a consistent

basis during construction, maintenance andmodification projects. According

to theNORSOK standards developed by theNorwegian petroleum industry

to ensure safety and value adding, technical safety is an overarching task in

project development and design processes. Also inmodification projects,

such as upgrading and tie‑in of satellite fields, technical safety should adjust

to project scope and complexity, according to the branch standard. The oil

and gas industry has a lot towin on changing its approach to the question

of technical safety. The challenge is to find optimisedways tomeet safety

obligationswhile ensuring business is as competitive as possible. Many

operators are battlingwith toomany layers of administration. Even small

modifications on platforms can end up passing through several costly layers

of projectmanagement in away that is no longer necessary. This belief has

led ALIGN to position itself as a specialist provider involved right fromthe

design study to the completedmodification project.

Promisingdevelopment

The relatively few commissions that until now have included a practical

implementation of technical safety on a holistic basis, point towards a

gradual shift in the industry’s behaviour.

Recently Talisman Energy in Norway concluded a safety EPCI‑C project

on an oil platformon the Norwegian Shelf, integrating safety into a larger

modification job based on a concept study carried out by Origo Solutions,

one of ALIGN’s brands. The study recommended broadmodifications

or replacements of switchgear and distribution boards, gas detectors,

the fire and gas system, emergency shutdown systems, control panels

for generators and other equipment. Unlike a traditional procedure, the

contractor carried out themodifications without taking the platformout

of production. The key was to integrate safety expertise across the project

phases.

“ALIGN had the project all from the start, and carried out a

complicated installation job to our full satisfaction”, says Talisman Energy

Project Manager Sigurd Oftedal.

Erik Christensen, ALIGN, Norway,

explains the benefits of increased integration

in technical safety for oil and gas operators.

|

67